How to tell if there was reversion/or leak with headers?

#11

Registered

By 'each one' you mean each header, surely?

I couldn't figure out how to check each cylinder separately.

Besides, it would be pointless: if there's any leak, the header has to be removed anyway, I suppose.

#12

Registered

Join Date: May 2003

Location: Lone Star State

Posts: 127

Likes: 0

Received 0 Likes

on

0 Posts

Yes, approximately 5 minutes per header. A leak would need to be dealt with by removing the header and replacing or repairing.

#14

Registered

Any good welder.... but.... most headers are heat treated and welding puts stresses into the stainless that can generate new cracks. Once you start welding on them you usually end up chasing cracks for ever. The other problem is the inside jacket may be coroded and is thinner in spots, likewhere it cracked. Welding can blow though and make holes, big mess!

I've had many headers welded in the past to get through a weekend or to finnish a season but a crack is a good sign it's time to replace. I just through out 2 sets for this reason. Leaking headers can cause some big $$$ in engine damage and I don't think it's worth the risk.

just my .02

I've had many headers welded in the past to get through a weekend or to finnish a season but a crack is a good sign it's time to replace. I just through out 2 sets for this reason. Leaking headers can cause some big $$$ in engine damage and I don't think it's worth the risk.

just my .02

#15

Registered

Just to complicate things for you:

Leak checking doesn't always reveal a leak. When running the inner jacket is hot and the water jacket is cool. The differential heating will open up cracks that don't show up on a pressure check.

Leak checking doesn't always reveal a leak. When running the inner jacket is hot and the water jacket is cool. The differential heating will open up cracks that don't show up on a pressure check.

#16

Registered

Join Date: Jan 2004

Location: San Diego, California

Posts: 2,777

Likes: 0

Received 6 Likes

on

6 Posts

Mapism:

The CMI 496 sportubes are really good at getting water in the back two cylinders of even stock 496's with stock camshafts. They have very little or no downturn in the lower two cylinder tubes that enter the collecter area of the header and with some boats with captain's call or silent choice switchable exhaust or low fall to the transom exhaust outlets they can get a lot of water vapor and actual water in the header that will run downhill into those last two cylinders on the engine at idle.

We've seen this and damage on a lot of 496's with Sportubes on even stock engines!

I always reccomend welding some 1/4" high 45 degree slanted anti-reversion rings in the tips a few inches back towards the engine from the water injection point inside the tips. These will prevent a lot of water and water vapor from migrating back up the header which occurs along the inside diameter of the tube in what we call the 1/8" dead air boundry layer. Ya, thats right! air does not flow in this inside 1/8" thick boundry layer and in some cases it even moves backwards from standard exhaust pulsing without actual reversion. We see this damage on 496's even when the headers are not leaking from cracks in CMI's.

Best Regards,

Ray @ Raylar

The CMI 496 sportubes are really good at getting water in the back two cylinders of even stock 496's with stock camshafts. They have very little or no downturn in the lower two cylinder tubes that enter the collecter area of the header and with some boats with captain's call or silent choice switchable exhaust or low fall to the transom exhaust outlets they can get a lot of water vapor and actual water in the header that will run downhill into those last two cylinders on the engine at idle.

We've seen this and damage on a lot of 496's with Sportubes on even stock engines!

I always reccomend welding some 1/4" high 45 degree slanted anti-reversion rings in the tips a few inches back towards the engine from the water injection point inside the tips. These will prevent a lot of water and water vapor from migrating back up the header which occurs along the inside diameter of the tube in what we call the 1/8" dead air boundry layer. Ya, thats right! air does not flow in this inside 1/8" thick boundry layer and in some cases it even moves backwards from standard exhaust pulsing without actual reversion. We see this damage on 496's even when the headers are not leaking from cracks in CMI's.

Best Regards,

Ray @ Raylar

#17

Registered

Geez Ray, now you got my attention!

I surely would like to get more than the current 200 or so hours out of my engine, possibly with a kit of yours on it!...

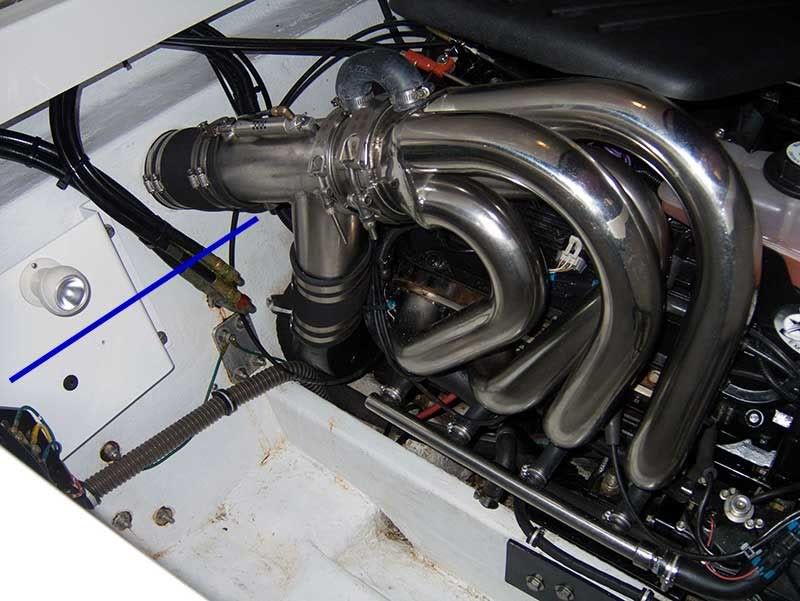

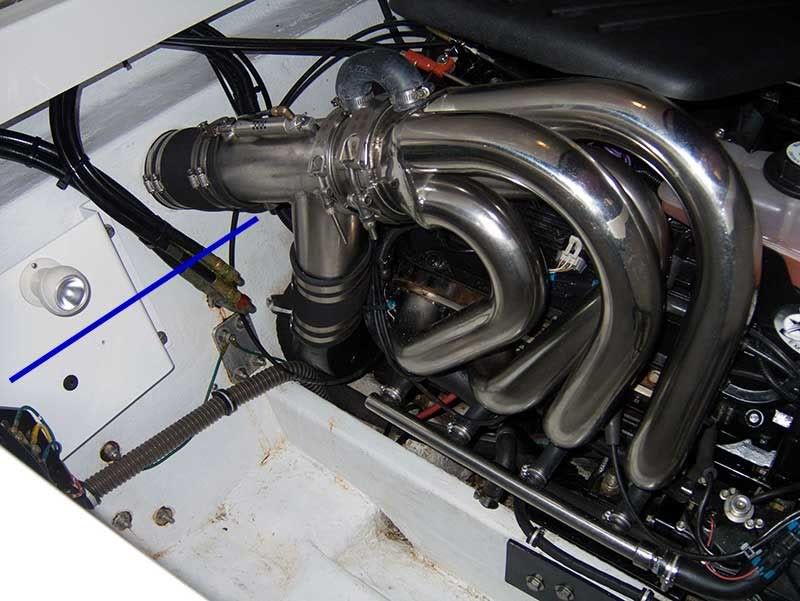

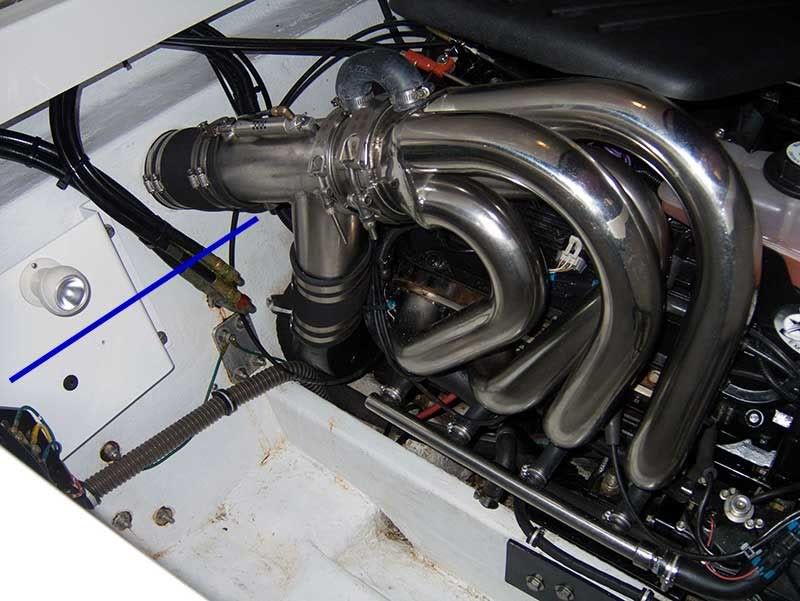

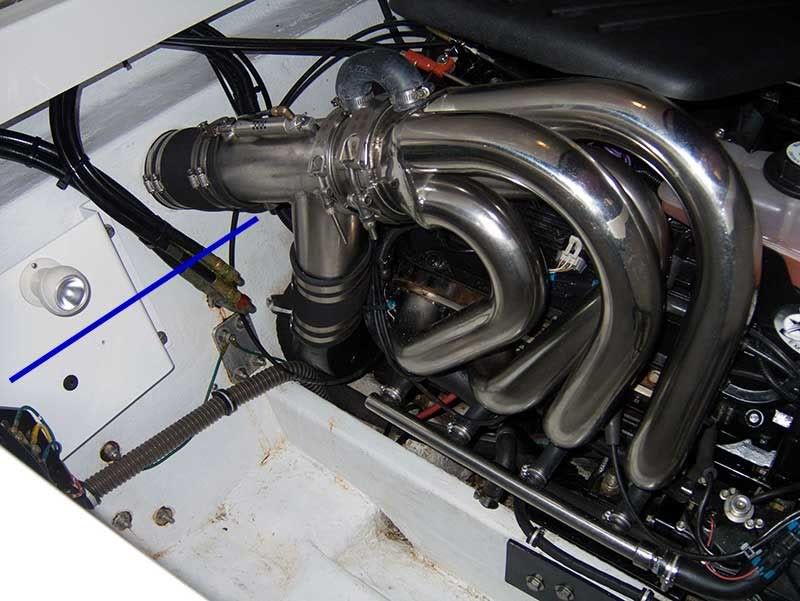

Let me see if I understood correctly what you mean, with the help of a pic of my engine compartment.

I added a blue line to show (approximately) the hull waterline.

First of all, by "the back two cylinders", do you mean the last one of each header (hence two in the engine overall), or the last two of each header (whose tubes enter the collector below the other two)? I guess you mean just the last one of each header, because I can clearly see that it has much less downturn than the others?

Secondly, isn't there already some sort of anti-reversion jacket inside these diverters, where the water injection rubber hose is connected?

Mind, the header was already installed when I bought the boat, and I never removed it, so I've never seen it inside.

But I guessed that there should be some protection, considering how near the water injection point is to the 4 tubes collector.

Another thing which should help is that the boat (Fever 27) sits pretty low in the water astern, so when the engine is idling the downward angle of the diverter and exhaust tip is even higher than it appears in the pic.

Anyhow, after 20 hours or so during this season, the engine seems to be running just fine - fingers crossed!...

Considering these premises, if you think that it's worth making the anti-reversion protection that you suggest, could you please describe it in more details? I mean, how should those rings be shaped, and where exactly should they be welded? I don't get it when you say "in the tips a few inches back towards the engine from the water injection point inside the tips".

...it might well be just a problem due to my poor english, please be patient...

Many, many thanks in advance!

I surely would like to get more than the current 200 or so hours out of my engine, possibly with a kit of yours on it!...

Let me see if I understood correctly what you mean, with the help of a pic of my engine compartment.

I added a blue line to show (approximately) the hull waterline.

First of all, by "the back two cylinders", do you mean the last one of each header (hence two in the engine overall), or the last two of each header (whose tubes enter the collector below the other two)? I guess you mean just the last one of each header, because I can clearly see that it has much less downturn than the others?

Secondly, isn't there already some sort of anti-reversion jacket inside these diverters, where the water injection rubber hose is connected?

Mind, the header was already installed when I bought the boat, and I never removed it, so I've never seen it inside.

But I guessed that there should be some protection, considering how near the water injection point is to the 4 tubes collector.

Another thing which should help is that the boat (Fever 27) sits pretty low in the water astern, so when the engine is idling the downward angle of the diverter and exhaust tip is even higher than it appears in the pic.

Anyhow, after 20 hours or so during this season, the engine seems to be running just fine - fingers crossed!...

Considering these premises, if you think that it's worth making the anti-reversion protection that you suggest, could you please describe it in more details? I mean, how should those rings be shaped, and where exactly should they be welded? I don't get it when you say "in the tips a few inches back towards the engine from the water injection point inside the tips".

...it might well be just a problem due to my poor english, please be patient...

Many, many thanks in advance!

Last edited by mapism; 12-01-2009 at 11:30 AM.

#18

Registered

Join Date: Oct 2002

Location: Menasha,WI

Posts: 285

Likes: 0

Received 0 Likes

on

0 Posts

Geez Ray, now you got my attention!

I surely would like to get more than the current 200 or so hours out of my engine, possibly with a kit of yours on it!...

Let me see if I understood correctly what you mean, with the help of a pic of my engine compartment.

I added a blue line to show (approximately) the hull waterline.

First of all, by "the back two cylinders", do you mean the last one of each header (hence two in the engine overall), or the last two of each header (whose tubes enter the collector below the other two)? I guess you mean just the last one of each header, because I can clearly see that it has much less downturn than the others?

Secondly, isn't there already some sort of anti-reversion jacket inside these diverters, where the water injection rubber hose is connected?

Mind, the header was already installed when I bought the boat, and I never removed it, so I've never seen it inside.

But I guessed that there should be some protection, considering how near the water injection point is to the 4 tubes collector.

Another thing which should help is that the boat (Fever 27) sits pretty low in the water astern, so when the engine is idling the downward angle of the diverter and exhaust tip is even higher than it appears in the pic.

Anyhow, after 20 hours or so during this season, the engine seems to be running just fine - fingers crossed!...

Considering these premises, if you think that it's worth making the anti-reversion protection that you suggest, could you please describe it in more details? I mean, how should those rings be shaped, and where exactly should they be welded? I don't get it when you say "in the tips a few inches back towards the engine from the water injection point inside the tips".

...it might well be just a problem due to my poor english, please be patient...

Many, many thanks in advance!

I surely would like to get more than the current 200 or so hours out of my engine, possibly with a kit of yours on it!...

Let me see if I understood correctly what you mean, with the help of a pic of my engine compartment.

I added a blue line to show (approximately) the hull waterline.

First of all, by "the back two cylinders", do you mean the last one of each header (hence two in the engine overall), or the last two of each header (whose tubes enter the collector below the other two)? I guess you mean just the last one of each header, because I can clearly see that it has much less downturn than the others?

Secondly, isn't there already some sort of anti-reversion jacket inside these diverters, where the water injection rubber hose is connected?

Mind, the header was already installed when I bought the boat, and I never removed it, so I've never seen it inside.

But I guessed that there should be some protection, considering how near the water injection point is to the 4 tubes collector.

Another thing which should help is that the boat (Fever 27) sits pretty low in the water astern, so when the engine is idling the downward angle of the diverter and exhaust tip is even higher than it appears in the pic.

Anyhow, after 20 hours or so during this season, the engine seems to be running just fine - fingers crossed!...

Considering these premises, if you think that it's worth making the anti-reversion protection that you suggest, could you please describe it in more details? I mean, how should those rings be shaped, and where exactly should they be welded? I don't get it when you say "in the tips a few inches back towards the engine from the water injection point inside the tips".

...it might well be just a problem due to my poor english, please be patient...

Many, many thanks in advance!

You may want to investigate the water system for proper flow and volume. The incomplete fill of the header causing the discoloration is more of a cause for concern.

#20

Registered

Join Date: Jan 2004

Location: San Diego, California

Posts: 2,777

Likes: 0

Received 6 Likes

on

6 Posts

Mapism & JRZ:

Pictures can be a bit decieving and distorting with respect to angles and dimensions, but what I am talking about there is the lower two tubes on each header on each side. If you get into the engine compartment and look straight over at the header you will see that where these two tubes enter the collector with the other two tubes, the lower two tubes have almost no real downturn or angle on them, maybe a 1/4" or so, couple this with the fact that when you install CMI's captain's call switchable system as you have Mapism, the distance now from the water exit in the tip to this low point for the two lower tubes (back cylinders) has been shortened by over 4" on one side and slightly more on the other. This is putting the water into the header so close to the low tubes and the collector thats its almost impossible to keep water and heavy water vapor (steam) out of the engine and especially the back cylinders.

This is one of the reasons I also don't like switchable or captain's call type switchable exhausts on Performance engines . these systems were a stopgap measure at best many years ago on smaller engines with less power.

When you are idling the engine the water mixed with exhaust gas is hitting at an almost right angle(obstruction) on the blade of the switchable exhaust, it causes exhaust gas mixed heavily with water to strike the plate with some velocity and bounce back into the exhaust stream with the pulses of a 4 cycle engine and with this location so close to those lower tubes with almost no real downturn or angle, you have a reciepe for slow damage and ultimate disaster!

This problem does not show up with all CMI headers or manifold systems, but this problem is amplified with this any header system where with your boat like a lot of other 23-28 foot boats the Bravo dimensions put the collector of the header so close to the switchable blade. You most likely have and I would suspect on a closer inspection or teardown you will find water and moisture damage in your rear cylinders. If I am wrong, then I will eat the CROW!

Hate to scare the hell out of everyone with 496 Sporttube systems, but there have been just to many 496 engines , even stock ones suffering from rear cylinder water damage.

I suspect most are the ones with the switchable systems described here.

Best Regards,

Ray @ Raylar

Pictures can be a bit decieving and distorting with respect to angles and dimensions, but what I am talking about there is the lower two tubes on each header on each side. If you get into the engine compartment and look straight over at the header you will see that where these two tubes enter the collector with the other two tubes, the lower two tubes have almost no real downturn or angle on them, maybe a 1/4" or so, couple this with the fact that when you install CMI's captain's call switchable system as you have Mapism, the distance now from the water exit in the tip to this low point for the two lower tubes (back cylinders) has been shortened by over 4" on one side and slightly more on the other. This is putting the water into the header so close to the low tubes and the collector thats its almost impossible to keep water and heavy water vapor (steam) out of the engine and especially the back cylinders.

This is one of the reasons I also don't like switchable or captain's call type switchable exhausts on Performance engines . these systems were a stopgap measure at best many years ago on smaller engines with less power.

When you are idling the engine the water mixed with exhaust gas is hitting at an almost right angle(obstruction) on the blade of the switchable exhaust, it causes exhaust gas mixed heavily with water to strike the plate with some velocity and bounce back into the exhaust stream with the pulses of a 4 cycle engine and with this location so close to those lower tubes with almost no real downturn or angle, you have a reciepe for slow damage and ultimate disaster!

This problem does not show up with all CMI headers or manifold systems, but this problem is amplified with this any header system where with your boat like a lot of other 23-28 foot boats the Bravo dimensions put the collector of the header so close to the switchable blade. You most likely have and I would suspect on a closer inspection or teardown you will find water and moisture damage in your rear cylinders. If I am wrong, then I will eat the CROW!

Hate to scare the hell out of everyone with 496 Sporttube systems, but there have been just to many 496 engines , even stock ones suffering from rear cylinder water damage.

I suspect most are the ones with the switchable systems described here.

Best Regards,

Ray @ Raylar