Confused - my new oil rings are much thinner than originals

#1

Putting together my bottom end (489), and it looks like I may have the wrong oil control rings. Original rings measured about .157 in radial thickness and .017 in vertical thickness, and had probably about a 3/8" gap when installed on the piston. The rings that came with my new set (PN 4285MS-15) measure about 0.11 in radial thickness and .030 in vertical thickness. The compression rings both look to be the same as the originals. I looked through Mahle's online catalog, and this part number appears to be the correct one for my pistons. Starting to wonder if these are low tension rings and I had standard tension rings previously.

This sucks - was planning to have the bottom end together this weekend. Motor only had 30 hours on it, and was torn down because of cam spalling and a small amount of metal that went through the bearings. I'm tempted to run the new compression rings and reuse the oil rings. Engine was holding 185+ PSI previously with no oil control issues.

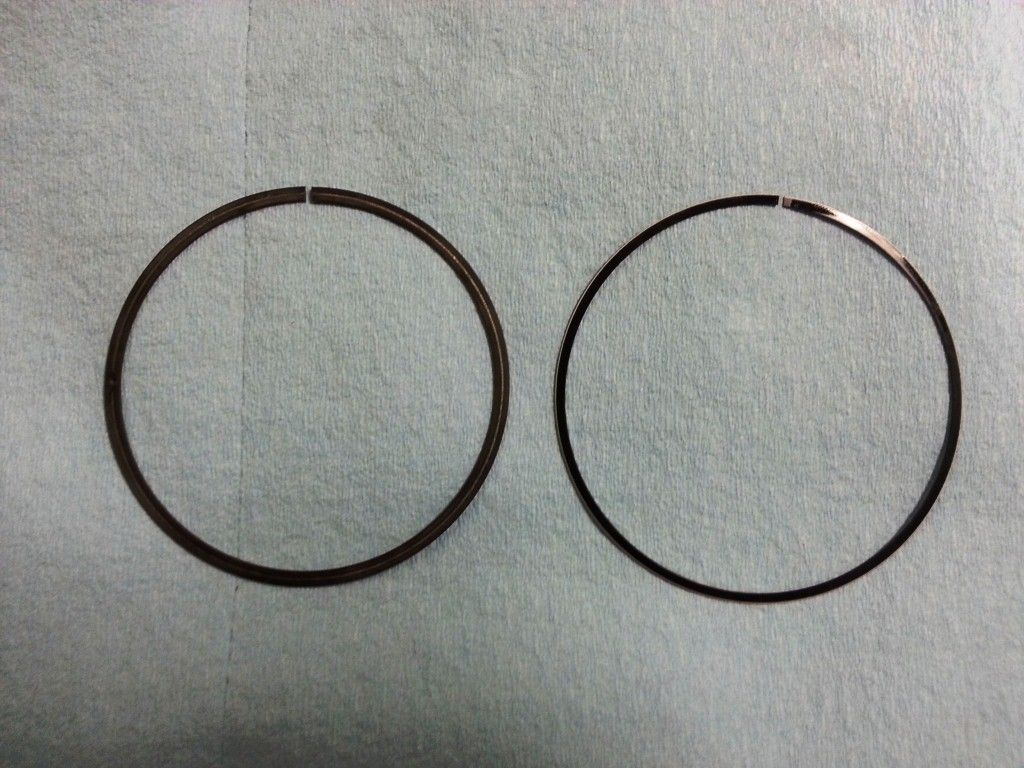

In picture below, original ring is on the left:

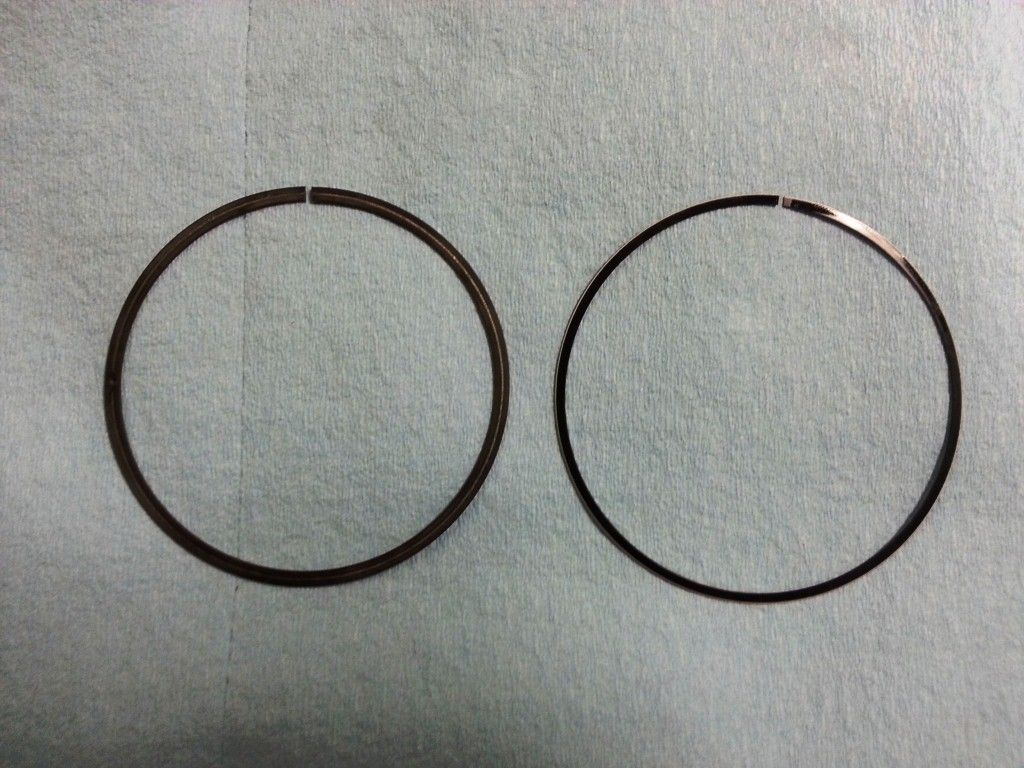

Another picture showing the difference in radial thickness:

Anyone ever run into this when ordering rings?

This sucks - was planning to have the bottom end together this weekend. Motor only had 30 hours on it, and was torn down because of cam spalling and a small amount of metal that went through the bearings. I'm tempted to run the new compression rings and reuse the oil rings. Engine was holding 185+ PSI previously with no oil control issues.

In picture below, original ring is on the left:

Another picture showing the difference in radial thickness:

Anyone ever run into this when ordering rings?

#4

Registered

how do the oil rings fit the pistons? if they are a mistake, the oil ring groove will swallow them. if they are a redesign, the new spacer with them will work just fine. on the other hand, you know your old oil rings work. and they were in a boat. not 165k in a truck. they ain't worn out...

#5

how do the oil rings fit the pistons? if they are a mistake, the oil ring groove will swallow them. if they are a redesign, the new spacer with them will work just fine. on the other hand, you know your old oil rings work. and they were in a boat. not 165k in a truck. they ain't worn out...

#6

Registered

Join Date: Dec 2012

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

Mahle has gone to metric ring packs on most of their piston packages now and they are substantially different. Also some different oil ring package types support the rails differently off the expander and they look different. When you assemble the oil ring (all three pieces) in the piston, do they fit, look and measure right for proper fit?

Also good advice here to check with Mahel if they supplied the rings with the pistons.

Good Luck

Also good advice here to check with Mahel if they supplied the rings with the pistons.

Good Luck

#7

Mahle has gone to metric ring packs on most of their piston packages now and they are substantially different. Also some different oil ring package types support the rails differently off the expander and they look different. When you assemble the oil ring (all three pieces) in the piston, do they fit, look and measure right for proper fit?

Also good advice here to check with Mahel if they supplied the rings with the pistons.

Good Luck

Also good advice here to check with Mahel if they supplied the rings with the pistons.

Good Luck

Thanks for the replies.

#8

Registered

iTrader: (2)

Join Date: Aug 2005

Location: Between A Womans Leggs in IL

Posts: 6,306

Likes: 0

Received 1 Like

on

1 Post

If all yourdoing is disassembling the block and cleaning out the crud and you did not hone the cylinders their is nothing wrong with reusing the rings..i have done it in the past with out any issues..i have also ran a ball hone through a cylinder and scuffed up the rings with a \grey scotch bright pad with no issues..i would not use those rings,,make sure the pistons are real clean and reuse the old rings..

#10

Registered

iTrader: (3)

If all yourdoing is disassembling the block and cleaning out the crud and you did not hone the cylinders their is nothing wrong with reusing the rings..i have done it in the past with out any issues..i have also ran a ball hone through a cylinder and scuffed up the rings with a \grey scotch bright pad with no issues..i would not use those rings,,make sure the pistons are real clean and reuse the old rings..