The GM/Merc Rectangle port head. Discuss.

#41

I don't mind at all. Its a bit old school but it works. 509 cu , 10.3 comp, 630ish on the cam (roller of course) single plane, 850 race prep carb , msd, gm crank, good rods 32 degrees timing. There is a bit more little stuff but that kinda covers it. No porting, just built tough. They run like a clock. Knock on wood.

#42

Registered

on one of the many hard drives I have,there is a ton of cam specs and head data that I use to use for desk top dyno.will have to start searching for it.

#43

Registered

iTrader: (5)

As I went back to look at what you have there, I happen to notice you said "HP500" cam??? OMG.

Dude, what in gods name is that cam doing in a 555 cubic inch engine? lol.

Anyhow, the program with your combo is coming back around 490HP. Going from an 800 Carb to a dominator, only picked up about 7hp, which im not surprised. Your just not making enough power to take advantage of a bigger carb.

Going with the crane 651 specs, bumps it up slightly over 1HP per ci, to 570HP with a 1050.

Switching to a set of AFR 305's with CNC chamber, still with the 651 crane cam, made the numbers jump to 671HP with a 1050.

Dude, what in gods name is that cam doing in a 555 cubic inch engine? lol.

Anyhow, the program with your combo is coming back around 490HP. Going from an 800 Carb to a dominator, only picked up about 7hp, which im not surprised. Your just not making enough power to take advantage of a bigger carb.

Going with the crane 651 specs, bumps it up slightly over 1HP per ci, to 570HP with a 1050.

Switching to a set of AFR 305's with CNC chamber, still with the 651 crane cam, made the numbers jump to 671HP with a 1050.

#44

Registered

Here is the gist of a conversation that I have with guys on an almost daily basis.

We start talking about power output, budget, head choices, etc. When you are freshening up an engine completely and are replacing all of the head hardware, you are looking at about $1000 in parts. This includes Manley valves, ISKY (or similar) springs, Comp (or similar) retainers, locks, etc. You have about $600 in Manley Severe duty intake and Inconel exhaust valves and about $400 in the rest of the parts. These are just rough numbers. Now, whether you are freshening up the stock cast iron heads, aftermarket cast iron heads, or aftermarket aluminum heads, the price of the hardware is the same. It really doesn't matter as far as the price is concerned. The issue is that none of that hardware is interchangeable between the stock cast iron heads and aftermarket aluminum heads. The alum heads use longer valves (usually) with larger heads and smaller stems. They will not work in a stock cast iron head. Typically, the springs will install a little taller, so they won't work in a stock head. You get the picture. You are going to spend that $1000 one way or the other, but then you are stuck with it.

Now, the only difference you have is the price of the bare aftermarket heads. Let's say that you are looking at aluminum heads that sell for $1400 bare. You don't want to spend the money but you want more power. First, your heads need some work though. The guides are worn out so they need liners. Of course, they need a valve job and they need to be surfaced. None of that will help power though. You decide to do some port work to them. You will never do enough porting to them to make them flow as good as a decent aftermarket aluminum head though. It's one thing if you can do the port work yourself without actually making them worse. If you have to pay someone to do it, you could spend $500-$1000 for really nice port work. You have now eaten away at just about all of that $1400 cost of the new heads. Even if you don't port them, you can easily dump $500 or more into the stock heads just to make them fresh and usable. Now, the new heads are only $900 more. The more you spend on the stockers, the smaller that price gap gets. I realize that it's a bunch of money, but you will never get into a set that cheap again. If you want to change them in the future, not only will you have to buy the heads, but you will have to buy all of that hardware again. You are already going to dump a bunch of money into some dinosaurs, why not spend a little more, get all of the benefits that aftermarket heads offer and only buy it once.

Eddie

We start talking about power output, budget, head choices, etc. When you are freshening up an engine completely and are replacing all of the head hardware, you are looking at about $1000 in parts. This includes Manley valves, ISKY (or similar) springs, Comp (or similar) retainers, locks, etc. You have about $600 in Manley Severe duty intake and Inconel exhaust valves and about $400 in the rest of the parts. These are just rough numbers. Now, whether you are freshening up the stock cast iron heads, aftermarket cast iron heads, or aftermarket aluminum heads, the price of the hardware is the same. It really doesn't matter as far as the price is concerned. The issue is that none of that hardware is interchangeable between the stock cast iron heads and aftermarket aluminum heads. The alum heads use longer valves (usually) with larger heads and smaller stems. They will not work in a stock cast iron head. Typically, the springs will install a little taller, so they won't work in a stock head. You get the picture. You are going to spend that $1000 one way or the other, but then you are stuck with it.

Now, the only difference you have is the price of the bare aftermarket heads. Let's say that you are looking at aluminum heads that sell for $1400 bare. You don't want to spend the money but you want more power. First, your heads need some work though. The guides are worn out so they need liners. Of course, they need a valve job and they need to be surfaced. None of that will help power though. You decide to do some port work to them. You will never do enough porting to them to make them flow as good as a decent aftermarket aluminum head though. It's one thing if you can do the port work yourself without actually making them worse. If you have to pay someone to do it, you could spend $500-$1000 for really nice port work. You have now eaten away at just about all of that $1400 cost of the new heads. Even if you don't port them, you can easily dump $500 or more into the stock heads just to make them fresh and usable. Now, the new heads are only $900 more. The more you spend on the stockers, the smaller that price gap gets. I realize that it's a bunch of money, but you will never get into a set that cheap again. If you want to change them in the future, not only will you have to buy the heads, but you will have to buy all of that hardware again. You are already going to dump a bunch of money into some dinosaurs, why not spend a little more, get all of the benefits that aftermarket heads offer and only buy it once.

Eddie

#45

Registered

iTrader: (1)

Not sure if GM made any changes to their rectangle port cast iron heads in the past years, but those heads are known for cracking between the seats for whatever reason...probably because they're too thin in that area---???

Anyway, no matter what the reason may be, who would want to take a chance of reusing those GM heads again if they're known for cracking at random when there is such a wider selection of better aftermarket designed heads these days???

Even if an aluminum head design is out of the budget....at least buy a good a set of aftermarket iron heads such as the Dart Iron Eagle heads or something that is not so prone to cracking at random as the GM cast iron heads are known for doing so often. Just my .02 gang

Anyway, no matter what the reason may be, who would want to take a chance of reusing those GM heads again if they're known for cracking at random when there is such a wider selection of better aftermarket designed heads these days???

Even if an aluminum head design is out of the budget....at least buy a good a set of aftermarket iron heads such as the Dart Iron Eagle heads or something that is not so prone to cracking at random as the GM cast iron heads are known for doing so often. Just my .02 gang

Last edited by KAAMA; 01-19-2015 at 12:34 AM.

#48

Registered

#49

Registered

iTrader: (1)

I went down this SAME road once before when I first started out in this "hobby"

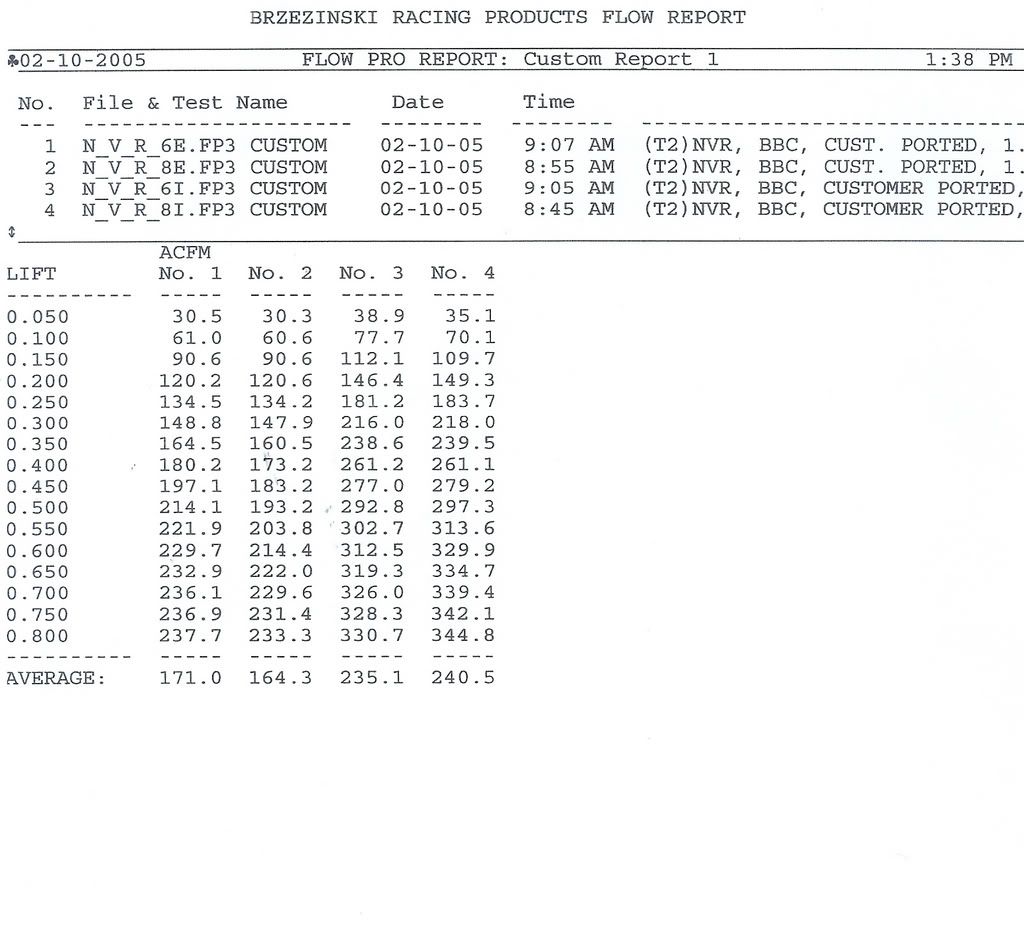

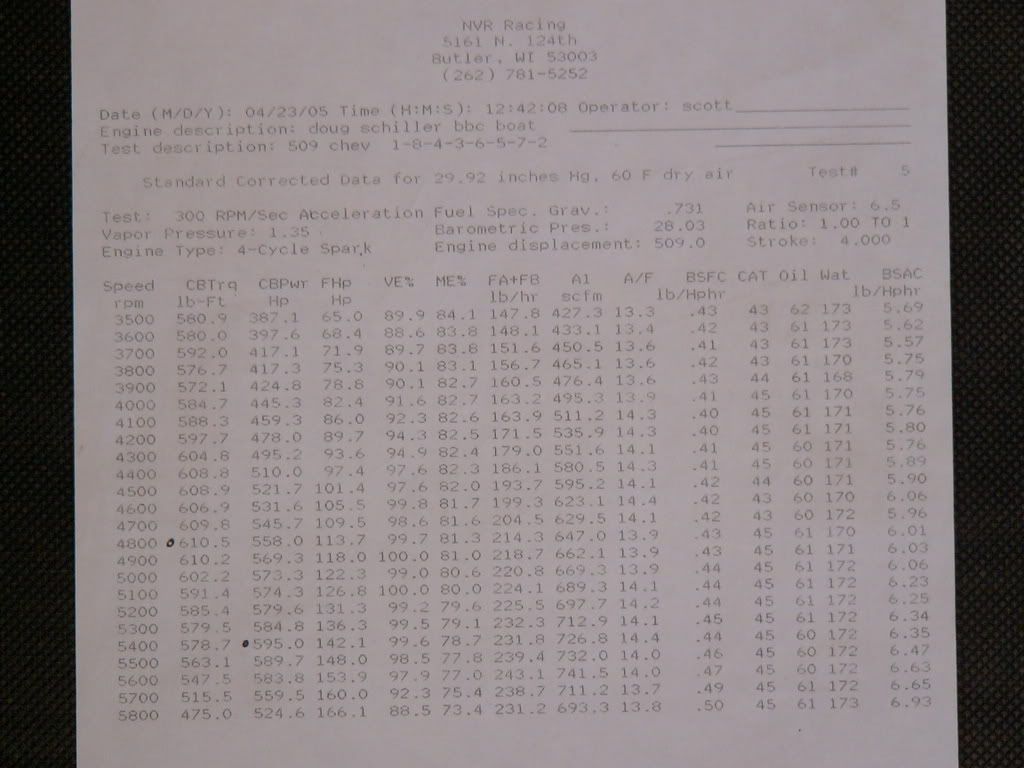

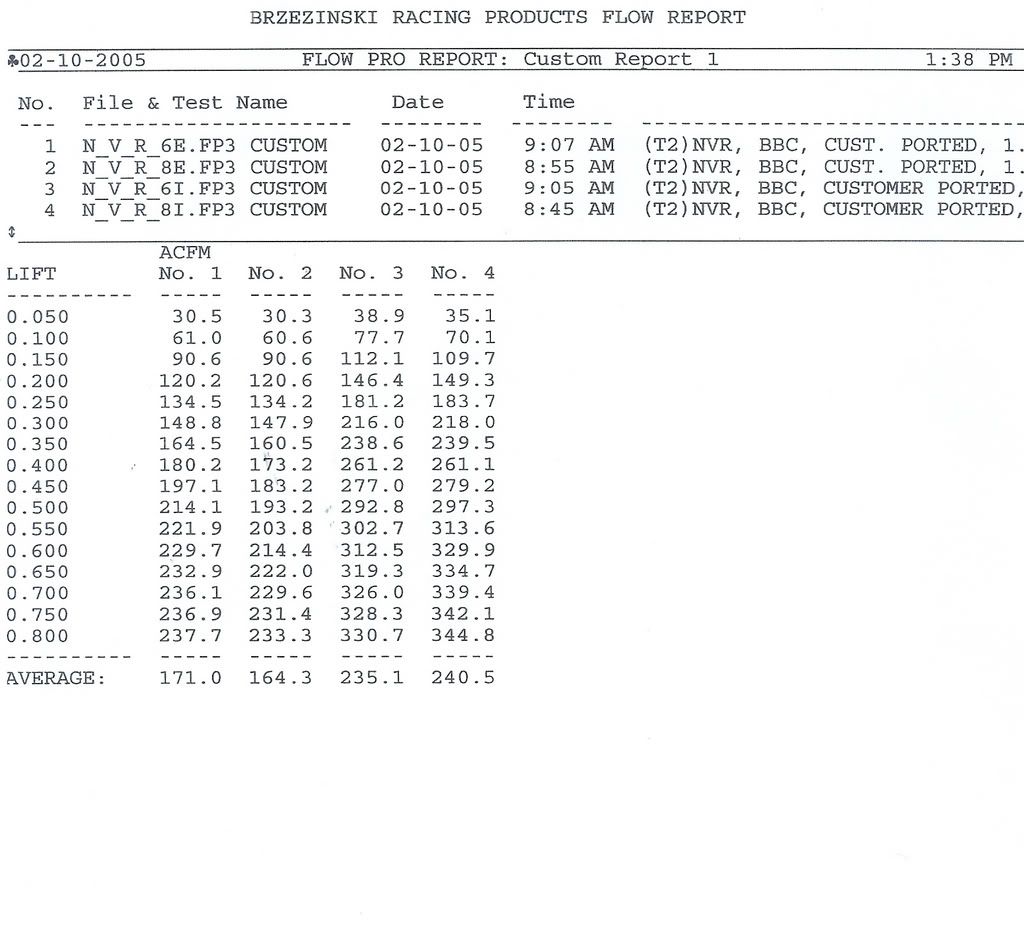

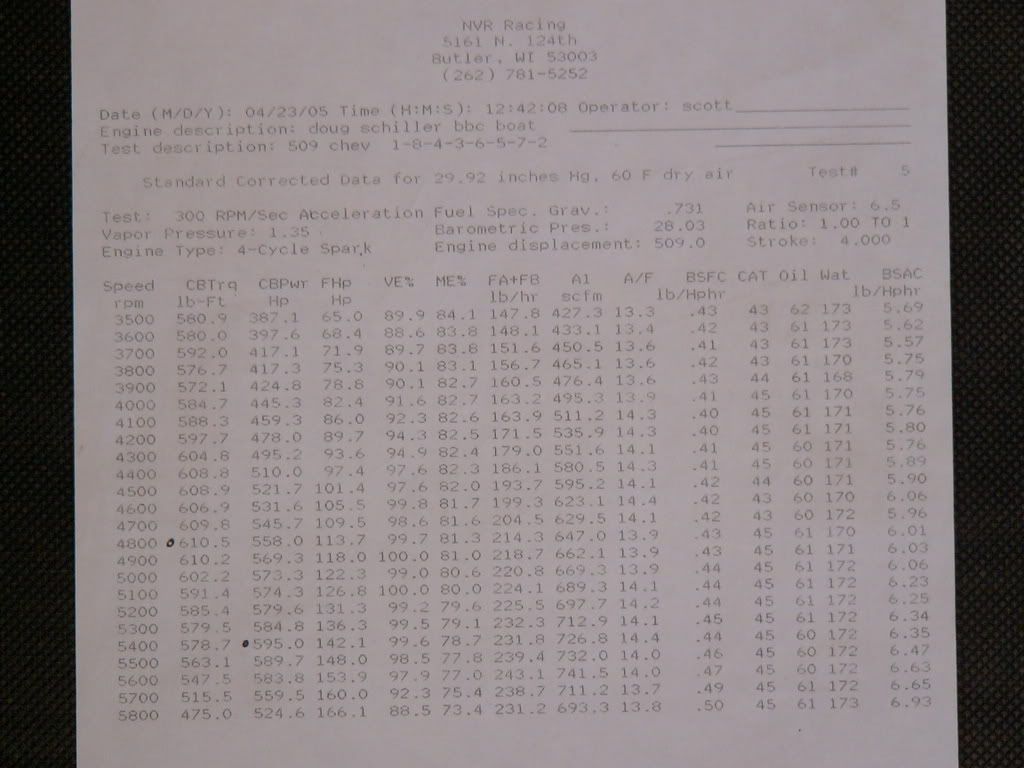

Spent some $$ having 088 casting GM iron heads custom ported at NVR racing with Manley 2.25 stainless intake and 1.9 inconel exhaust valves

Custom Ground Cam Motion cam (spec'd by rmbuilder)

Intake .594 lift 228 degrees duration at .050

Exhaust .600 lift 232.7 degrees duration at .050

112.2 degrees lobe separation 58 crank degrees overlap

509 cid...

Engine was dyno'd bare with car headers on it... I'm thinkin' the Dyno may have been set to be a bit optimistic as well....

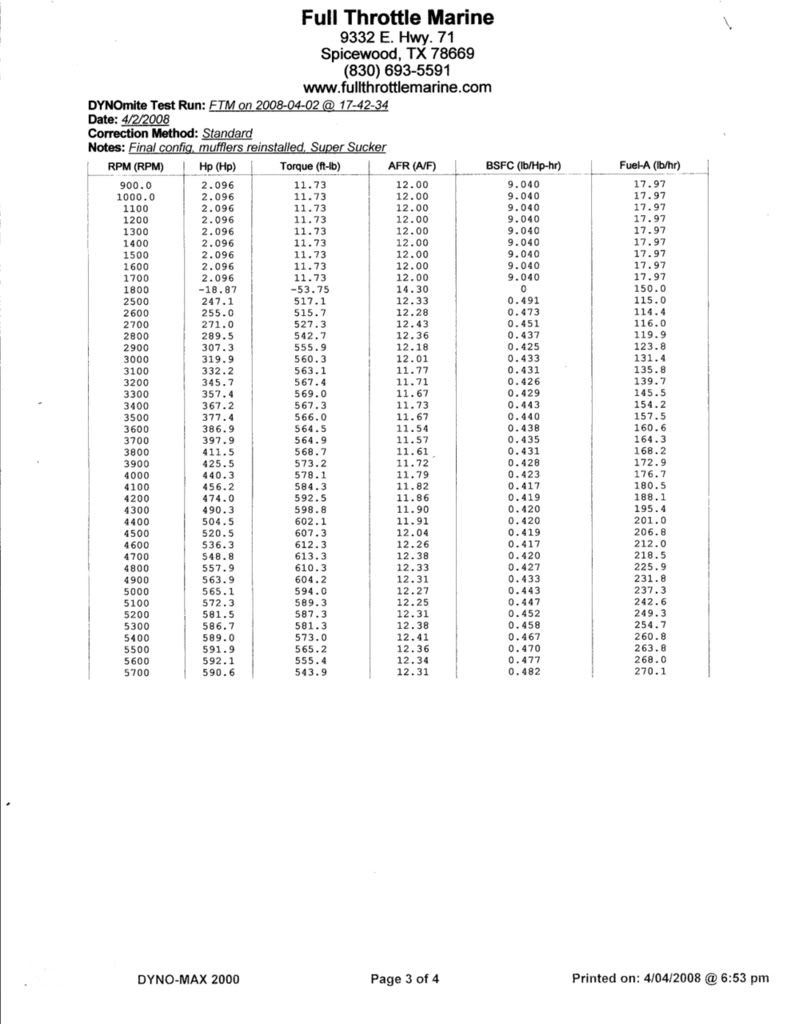

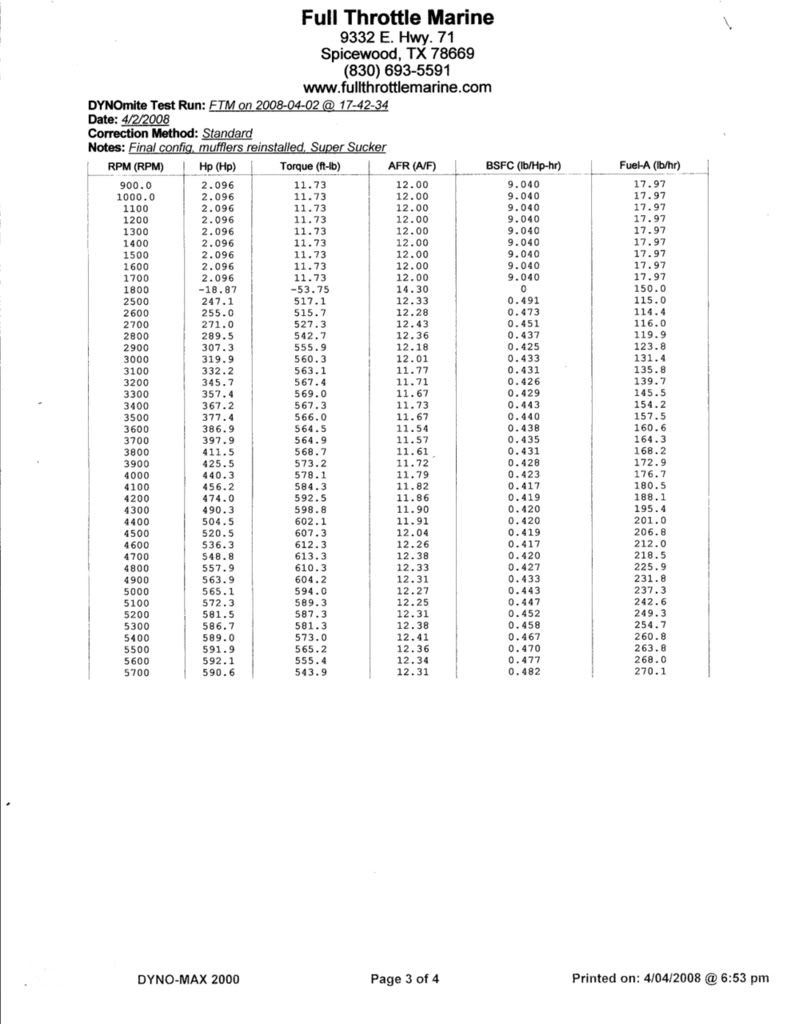

I refreshed the engine... Went another .030 over to a 516 cid..

Changed to AFR "305" heads CNC chambered, Inconel exhaust, hydraulic roller springs, hard anodized, flat milled to 114 CCs

Yet another Madera Cam..

Intake. .611" lift 231° duration. Exhaust .595" lift 238° duration. 112° lobe sep.

Ran it a Full Throttle Marine on a more accurate dyno I'm sure...

Full marine dress.. Even the mufflers this time....

Dyno results show I lost horsepower... Yet the boat accelerated MUCH harder and picked up 7 mph with the SAME prop..

Doug

Spent some $$ having 088 casting GM iron heads custom ported at NVR racing with Manley 2.25 stainless intake and 1.9 inconel exhaust valves

Custom Ground Cam Motion cam (spec'd by rmbuilder)

Intake .594 lift 228 degrees duration at .050

Exhaust .600 lift 232.7 degrees duration at .050

112.2 degrees lobe separation 58 crank degrees overlap

509 cid...

Engine was dyno'd bare with car headers on it... I'm thinkin' the Dyno may have been set to be a bit optimistic as well....

I refreshed the engine... Went another .030 over to a 516 cid..

Changed to AFR "305" heads CNC chambered, Inconel exhaust, hydraulic roller springs, hard anodized, flat milled to 114 CCs

Yet another Madera Cam..

Intake. .611" lift 231° duration. Exhaust .595" lift 238° duration. 112° lobe sep.

Ran it a Full Throttle Marine on a more accurate dyno I'm sure...

Full marine dress.. Even the mufflers this time....

Dyno results show I lost horsepower... Yet the boat accelerated MUCH harder and picked up 7 mph with the SAME prop..

Doug

Last edited by Boatally Insane; 01-19-2015 at 11:10 AM.

#50

Registered

iTrader: (4)

I will add this in regards to the flow numbers on Stain Weiss. I used to use the data from the Stan Weiss site as gold; however, with the new heads I bought, I was sent the flow data for them. On the sheet it shows the flow data for Dart 335 CNC heads, Brodix 2X ported heads, BB2 Plus, and AFR 305.

The Brodix BB2 Plus and the AFR 305 have very similar numbers on on the intake. Now looking at the Stan Weiss charts, the AFR head should blow away the Brodix BB2 Plus, however it isn't the case. The Brodix BB2 Plus and AFR 305 when being measured by the same person on the same flow bench are all about the same.

So my point with all of this is that while it can be fun to compare all of the data from one head to another, in the end it's kind of pointless. Unless the head was flowed on the same bench you really can't compare the information that accurately.

The Brodix BB2 Plus and the AFR 305 have very similar numbers on on the intake. Now looking at the Stan Weiss charts, the AFR head should blow away the Brodix BB2 Plus, however it isn't the case. The Brodix BB2 Plus and AFR 305 when being measured by the same person on the same flow bench are all about the same.

So my point with all of this is that while it can be fun to compare all of the data from one head to another, in the end it's kind of pointless. Unless the head was flowed on the same bench you really can't compare the information that accurately.