DIY - Duramax Marinisation

#52

Registered

Thread Starter

I've heard they will do 300MPa at low output volumes. Have any flow charts you can share?

Highest I've ever seen used in a LMM tune was like 200MPa at 125mm3. EFI max pressure limit value is 250MPa. Typically what I've found with large pulsewidth tunes or 40-60% oversized injectors is the stock gearotor pump can't keep up with commanded pressure at high RPM. Adding an electric lift pump seems to resolve that issue in most cases. Most common issue I see fuel filters plugged up when people drop a truck off to be tuned.

What's your experience with the 10mm or 12mm CP3 stroker pumps? I hear they are more reliable now than ones a few years back.

Highest I've ever seen used in a LMM tune was like 200MPa at 125mm3. EFI max pressure limit value is 250MPa. Typically what I've found with large pulsewidth tunes or 40-60% oversized injectors is the stock gearotor pump can't keep up with commanded pressure at high RPM. Adding an electric lift pump seems to resolve that issue in most cases. Most common issue I see fuel filters plugged up when people drop a truck off to be tuned.

What's your experience with the 10mm or 12mm CP3 stroker pumps? I hear they are more reliable now than ones a few years back.

#53

Registered

iTrader: (2)

According to everything I've read Dodge uses both an in-tank and gearotor pump from the factory.

http://www.cumminsforum.com/forum/3r...mp-system.html

GEAROTOR PUMP

DESCRIPTION

The gearotor pump has two functions

- draws fuel from the fuel supply

- increases fuel pressure for regulation to housing pressure required for internal lubrication and supplying the high-pressure injection pump

OPERATION

This fuel system uses a gearotor supply-pump attached to the rear of the high-pressure pump. This medium-pressure fuel pump is driven by the end of the high-pressure pump shaft, and can generate 20" vacuum at the fuel inlet at high rpm.

The gearotor pump is supplied fuel from the lift pump in the fuel tank through the fuel manager\filter.

--

[ATTACH=CONFIG]554361[/ATTACH]

The mechanical lift or "gearotor" pump is the aluminum piece attached by 4 torques head bolts above.

Dodge uses basically the same CP3 pump as the GM model, however GM didn't include an electric pusher pump to feed the gearotor pump. In my experience that gearotor can't handle much above 500hp fueling by itself. Even at slightly over stock power demands the ECM will "limp mode" if the fuel filter has some miles on it. The gear pump is constantly sucking fuel through the filter on GM's, as where everyone else prefers to push the fuel to the pump.

My 3.2L Mercedes does not have that gear pump on the CP3. It is totally supplied by an in-tank pusher pump. Being a German car, and one of the first models equipped with a CP3 makes me wonder why the change for US trucks.

Ultimately a combination of electric and mechanical is what all the high performance setups run. I added a 190gph lift pump in my boat pushing at 10-15psi and all fuel starvation issues were solved. Especially when running B100 fuel.

http://www.cumminsforum.com/forum/3r...mp-system.html

GEAROTOR PUMP

DESCRIPTION

The gearotor pump has two functions

- draws fuel from the fuel supply

- increases fuel pressure for regulation to housing pressure required for internal lubrication and supplying the high-pressure injection pump

OPERATION

This fuel system uses a gearotor supply-pump attached to the rear of the high-pressure pump. This medium-pressure fuel pump is driven by the end of the high-pressure pump shaft, and can generate 20" vacuum at the fuel inlet at high rpm.

The gearotor pump is supplied fuel from the lift pump in the fuel tank through the fuel manager\filter.

--

[ATTACH=CONFIG]554361[/ATTACH]

The mechanical lift or "gearotor" pump is the aluminum piece attached by 4 torques head bolts above.

Dodge uses basically the same CP3 pump as the GM model, however GM didn't include an electric pusher pump to feed the gearotor pump. In my experience that gearotor can't handle much above 500hp fueling by itself. Even at slightly over stock power demands the ECM will "limp mode" if the fuel filter has some miles on it. The gear pump is constantly sucking fuel through the filter on GM's, as where everyone else prefers to push the fuel to the pump.

My 3.2L Mercedes does not have that gear pump on the CP3. It is totally supplied by an in-tank pusher pump. Being a German car, and one of the first models equipped with a CP3 makes me wonder why the change for US trucks.

Ultimately a combination of electric and mechanical is what all the high performance setups run. I added a 190gph lift pump in my boat pushing at 10-15psi and all fuel starvation issues were solved. Especially when running B100 fuel.

Yeah its all that low end torque when the turbo lights off at around 1500rpm if your on the throttle. Engine goes from 400ft lbs to 1200ft lbs in under couple seconds. Soon as that prop starts to boiling the edges, its done. Bravo1 drives being limited to just under 15.5" diameter props, and 36" pitch off the shelf options doesn't help. That 4 blade 32P at 15" dia I first ran was like a 13" radial on a drag car. You can drive on it, just don't jump on the throttle.

Once I changed to 15.5" with 5 blades and stepped up to 35 pitch it wouldn't blow out, but you could still feel it cavitate until you backed off the throttle for a second. I see this same thing happening on my friends boat with the 6spd Allison and ASD8 between shifts. He can log the output shaft speeds, and that surface piercing prop will jump like 600-700rpm when shifted from 4th to 5th [OD]. After 5 or 10 seconds you can see it slow back down and hook up again in the logs. It's a torque thing...

The easy fix, that also helps protect the Bravo drives is using the ECM's torque limit table to map power curve by RPM. Once I modified the torque table you could slam the throttle down from a dead stop and she would climb nice and mellow until up on plane. [See Pic Below] Above 2000 R's I left it maxed out and unrestricted. After breaking the shift lever bolt off inside the outdrive, I used that same table to limit idle torque to 50ft lbs. Nice feature you get with EFIlive...

[ATTACH=CONFIG]553735[/ATTACH]

Once I changed to 15.5" with 5 blades and stepped up to 35 pitch it wouldn't blow out, but you could still feel it cavitate until you backed off the throttle for a second. I see this same thing happening on my friends boat with the 6spd Allison and ASD8 between shifts. He can log the output shaft speeds, and that surface piercing prop will jump like 600-700rpm when shifted from 4th to 5th [OD]. After 5 or 10 seconds you can see it slow back down and hook up again in the logs. It's a torque thing...

The easy fix, that also helps protect the Bravo drives is using the ECM's torque limit table to map power curve by RPM. Once I modified the torque table you could slam the throttle down from a dead stop and she would climb nice and mellow until up on plane. [See Pic Below] Above 2000 R's I left it maxed out and unrestricted. After breaking the shift lever bolt off inside the outdrive, I used that same table to limit idle torque to 50ft lbs. Nice feature you get with EFIlive...

[ATTACH=CONFIG]553735[/ATTACH]

#54

Registered

I've heard they will do 300MPa at low output volumes. Have any flow charts you can share?

Highest I've ever seen used in a LMM tune was like 200MPa at 125mm3. EFI max pressure limit value is 250MPa. Typically what I've found with large pulsewidth tunes or 40-60% oversized injectors is the stock gearotor pump can't keep up with commanded pressure at high RPM. Adding an electric lift pump seems to resolve that issue in most cases. Most common issue I see fuel filters plugged up when people drop a truck off to be tuned.

What's your experience with the 10mm or 12mm CP3 stroker pumps? I hear they are more reliable now than ones a few years back.

Highest I've ever seen used in a LMM tune was like 200MPa at 125mm3. EFI max pressure limit value is 250MPa. Typically what I've found with large pulsewidth tunes or 40-60% oversized injectors is the stock gearotor pump can't keep up with commanded pressure at high RPM. Adding an electric lift pump seems to resolve that issue in most cases. Most common issue I see fuel filters plugged up when people drop a truck off to be tuned.

What's your experience with the 10mm or 12mm CP3 stroker pumps? I hear they are more reliable now than ones a few years back.

#55

Registered

Thread Starter

Second I have a question I hope you can answer. I also have a turbo benz with torque limiting, while I understand you can control torque output through software settings what is physically happening in the engine to limit torque output? Is it boost being bled, fuel reduced??? I have never understood how this works.

Requested torque tables control the commanded fuel, by using Nm calculations based on driving modes, 4x4 range and such. You have the requested torque tables above that says "x" Nm based on throttle % and RPM.

[ATTACH=CONFIG]554401[/ATTACH]

The next table then provides total commanded fuel that the engine gets fed. A third table takes that mm3 info above and uses fuel pressure values to calculate how long to open the injectors. The RPM torque limit table overrides all those requests based on max values set there. No matter what the engine wants, the torque limit tables control the peak based simply on RPM.

There is a whole different set of tables that limit torque based on CANbus requests from transmission or stability control. When the Allison shifts, it will request the engine to torque limit between gears. Same goes with traction control. These are all network data requests,also used in diesel and gas cars like your MB.

I'm attempting to hack those torque limit messages right now actually. Goal is to use a button on the wheel, or a dive based sensor to torque limit the engine when the drives leave the water. IE: set the throttles at 80% and never touch them again no matter how far/long the boat leave the water. Like traction control for a boat..

Last edited by kidturbo; 04-20-2016 at 08:29 PM.

#56

Registered

iTrader: (2)

Like they say keep it simple. I guess I was overthinking it. Makes sense now that you explained to me. The boost is a result of the fuel wouldn't make sense to try to control it by bleeding off boost. I wish it was that easy to play with the fuel map on the MB, problem is I doubt the transmission can handle much more torque.

Changing gears to the Yanmar 6LP my "map" is screws, springs, pins, and diaphragms. Do you know if this software (or similar) will work on any common rail marine diesels? Cummins 550, FPT 570, Yanmar 8LV 370, the Mercruiser 370 (I think still a VW motor), Steyr.

Changing gears to the Yanmar 6LP my "map" is screws, springs, pins, and diaphragms. Do you know if this software (or similar) will work on any common rail marine diesels? Cummins 550, FPT 570, Yanmar 8LV 370, the Mercruiser 370 (I think still a VW motor), Steyr.

#57

Registered

Thread Starter

For $100 off eBay you can trick the ECM to believing rail pressure is lower than actual. Thus the ECM adds more fuel pressure, and that increases the power output. I've considered trying one

#58

Registered

Thread Starter

Back to fuel supply

Below is a stock filter head showing the primmer button and a pressure sensor in the bleeder port. Normally that port will have a vacuum on it unless you run an electric lift pump. I'll stick a simple mechanical gauge in that same port to set the lift pump pressure to 10-15psi. While the stock filter unit works ok into the 700hp range, it's not the best choice for marine applications.

[ATTACH=CONFIG]554407[/ATTACH]

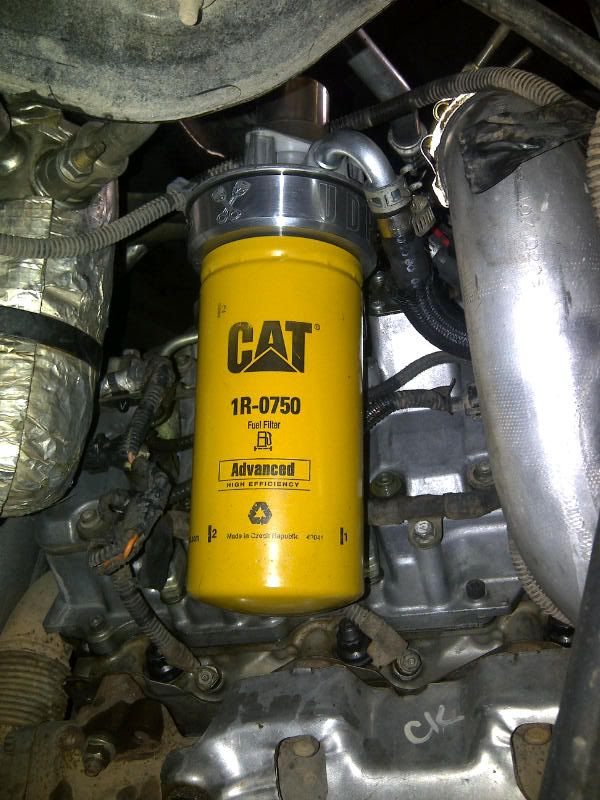

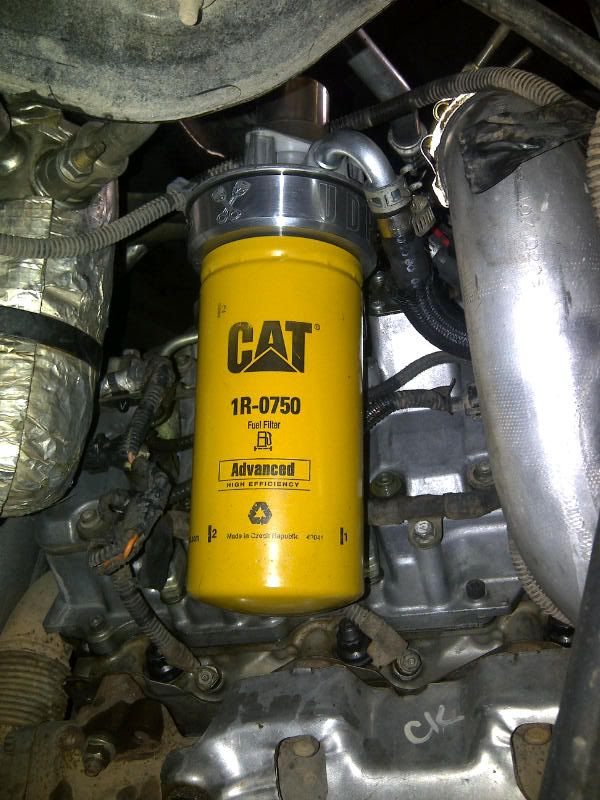

First that primmer button on top tends to start leaking if you run a lift pump. Simple rebuild, just pain.. Second it has a fuel heater built in that you likely won't need. Third those GM filters are an uncommon design and fairly expensive. So someone came up with an adapter to take a standard 2 micron CAT filter. If using the standard head assembly, you'll be way ahead to upgrade to this CAT filter setup.

For those looking to upgrade the filter or add a lift pump we have plenty of options based on power levels. For stock or slightly elevated power a 120gph lift pump will do the trick. I ran the adjustable pressure 160gph model [incorrectly listed as 190gph above] in the Warlock at 650hp. This rotary vane pump is built by SX performance. Pump is re branded under Edelbrock, PPE, and Jegs to name a few. Nice thing about these pumps, it's not very expensive, and because of the rotary design, if it fails the mechanical lift will still pull fuel through it to get you home. They are rebuildbable, while I put 4 years on mine with no issues.

[ATTACH=CONFIG]554408[/ATTACH] [ATTACH=CONFIG]554409[/ATTACH]

PPE and Edelbrock 160gph units sell for $260. Jegs units are $219.

Those pumps can be used with a stock, Racor, or CAT filter head assembly as pictured below. Unless going serious power levels or constant offshore running, that's my lift pump choice. Your just helping out the gearotor pump on the CP3. Just remember these 2 points, rated flow volume, and correct micron rating. Five micron tops, and two micron is what I would recommend if you can manage it.

[ATTACH=CONFIG]554410[/ATTACH] [ATTACH=CONFIG]554412[/ATTACH] [ATTACH=CONFIG]554411[/ATTACH]

For those looking to make 800+hp, or with plans to seriously agitate the fuel tanks, the starting price doubles. Two leaders in "air removal" pump market are FASS and Airdog pumps. These units are designed to separate air bubbles from the fuel supply by returning part of the fuel back to the tank. Since the Duramax fuel system also returns fuel, you'll need a extra port in the tanks either way. Here is a good video I found that explains this air removal process. https://youtu.be/ujokaEkF8Z0

FASS $500 - $800

Flow Rate

220gph @ 8-10psi

[ATTACH=CONFIG]554414[/ATTACH]

Airdog pumps $690 and up.

Last point is powering the pump. Because it's diesel, we can get away with running electric fuel pumps in the bilge without the Coast Guard freaking out on ya.. However to be safe I suggest running an oil pressure safety switch in the system. The Duramax has several extra ports in the block to add a pressure safety switch. The engine will fire up fine without the added fuel pressure. Wire the safety switch in with a momentary-on push button for priming the system, and replacing fuel filters is now a 3 minute job max.

That's about all I have on lift pumps and fuel filters. Positive I've missed some other good marine diesel options.

Below is a stock filter head showing the primmer button and a pressure sensor in the bleeder port. Normally that port will have a vacuum on it unless you run an electric lift pump. I'll stick a simple mechanical gauge in that same port to set the lift pump pressure to 10-15psi. While the stock filter unit works ok into the 700hp range, it's not the best choice for marine applications.

[ATTACH=CONFIG]554407[/ATTACH]

First that primmer button on top tends to start leaking if you run a lift pump. Simple rebuild, just pain.. Second it has a fuel heater built in that you likely won't need. Third those GM filters are an uncommon design and fairly expensive. So someone came up with an adapter to take a standard 2 micron CAT filter. If using the standard head assembly, you'll be way ahead to upgrade to this CAT filter setup.

For those looking to upgrade the filter or add a lift pump we have plenty of options based on power levels. For stock or slightly elevated power a 120gph lift pump will do the trick. I ran the adjustable pressure 160gph model [incorrectly listed as 190gph above] in the Warlock at 650hp. This rotary vane pump is built by SX performance. Pump is re branded under Edelbrock, PPE, and Jegs to name a few. Nice thing about these pumps, it's not very expensive, and because of the rotary design, if it fails the mechanical lift will still pull fuel through it to get you home. They are rebuildbable, while I put 4 years on mine with no issues.

[ATTACH=CONFIG]554408[/ATTACH] [ATTACH=CONFIG]554409[/ATTACH]

PPE and Edelbrock 160gph units sell for $260. Jegs units are $219.

Those pumps can be used with a stock, Racor, or CAT filter head assembly as pictured below. Unless going serious power levels or constant offshore running, that's my lift pump choice. Your just helping out the gearotor pump on the CP3. Just remember these 2 points, rated flow volume, and correct micron rating. Five micron tops, and two micron is what I would recommend if you can manage it.

[ATTACH=CONFIG]554410[/ATTACH] [ATTACH=CONFIG]554412[/ATTACH] [ATTACH=CONFIG]554411[/ATTACH]

For those looking to make 800+hp, or with plans to seriously agitate the fuel tanks, the starting price doubles. Two leaders in "air removal" pump market are FASS and Airdog pumps. These units are designed to separate air bubbles from the fuel supply by returning part of the fuel back to the tank. Since the Duramax fuel system also returns fuel, you'll need a extra port in the tanks either way. Here is a good video I found that explains this air removal process. https://youtu.be/ujokaEkF8Z0

FASS $500 - $800

Flow Rate

220gph @ 8-10psi

[ATTACH=CONFIG]554414[/ATTACH]

Airdog pumps $690 and up.

Last point is powering the pump. Because it's diesel, we can get away with running electric fuel pumps in the bilge without the Coast Guard freaking out on ya.. However to be safe I suggest running an oil pressure safety switch in the system. The Duramax has several extra ports in the block to add a pressure safety switch. The engine will fire up fine without the added fuel pressure. Wire the safety switch in with a momentary-on push button for priming the system, and replacing fuel filters is now a 3 minute job max.

That's about all I have on lift pumps and fuel filters. Positive I've missed some other good marine diesel options.

Last edited by kidturbo; 04-21-2016 at 12:55 AM.

#59

Registered

I forgot to go over the oil pan options before getting into the fuel system. So taking a step back for a minute.

The factory pan is two piece setup with a built in windage tray design. Likely this will work fine in most situations. I've yet to hear any issues with these in a boat, no matter how much wave jumping you do. The medium duty oil pan has a bit larger volume. I couldn't find a pic of one right off. All the Duramax models have a low oil level sensor in them. After some testing, I have serious reservations if the ECM will even report a low oil level... But you could easily wire that sensor to a light or audiable alarm and be safe.

[ATTACH=CONFIG]554119[/ATTACH]

Below is the stock light duty upper, and comparison of stock steel lower and the aftermarket aluminum "Banana Pan." No matter which one you chose, be sure to install a drain hose or tube so you can pump it out in the boat. I forgot to add one when I had the engine out first time, and it was a real pain to install in the boat. Pumping it out the dipstick is not an option either...

[ATTACH=CONFIG]554111[/ATTACH] [ATTACH=CONFIG]554114[/ATTACH] [ATTACH=CONFIG]554117[/ATTACH]

For those looking to do some serious power and heavy offshore running, dry sump pans are available. Here is an example of a custom built unit, along with cast models. First cast model was by Curtis Halvorson from Extreme Engine Development. Last two pics are the PPE version release a couple years ago.

[ATTACH=CONFIG]554112[/ATTACH] [ATTACH=CONFIG]554113[/ATTACH] [ATTACH=CONFIG]554115[/ATTACH] [ATTACH=CONFIG]554116[/ATTACH]

Last is a pic I took of a HP4 filter head my friend was installing in a hot rod build this week. I liked the connection options and felt was worth posting here.

[ATTACH=CONFIG]554120[/ATTACH]

Back to the fuel system now.

The factory pan is two piece setup with a built in windage tray design. Likely this will work fine in most situations. I've yet to hear any issues with these in a boat, no matter how much wave jumping you do. The medium duty oil pan has a bit larger volume. I couldn't find a pic of one right off. All the Duramax models have a low oil level sensor in them. After some testing, I have serious reservations if the ECM will even report a low oil level... But you could easily wire that sensor to a light or audiable alarm and be safe.

[ATTACH=CONFIG]554119[/ATTACH]

Below is the stock light duty upper, and comparison of stock steel lower and the aftermarket aluminum "Banana Pan." No matter which one you chose, be sure to install a drain hose or tube so you can pump it out in the boat. I forgot to add one when I had the engine out first time, and it was a real pain to install in the boat. Pumping it out the dipstick is not an option either...

[ATTACH=CONFIG]554111[/ATTACH] [ATTACH=CONFIG]554114[/ATTACH] [ATTACH=CONFIG]554117[/ATTACH]

For those looking to do some serious power and heavy offshore running, dry sump pans are available. Here is an example of a custom built unit, along with cast models. First cast model was by Curtis Halvorson from Extreme Engine Development. Last two pics are the PPE version release a couple years ago.

[ATTACH=CONFIG]554112[/ATTACH] [ATTACH=CONFIG]554113[/ATTACH] [ATTACH=CONFIG]554115[/ATTACH] [ATTACH=CONFIG]554116[/ATTACH]

Last is a pic I took of a HP4 filter head my friend was installing in a hot rod build this week. I liked the connection options and felt was worth posting here.

[ATTACH=CONFIG]554120[/ATTACH]

Back to the fuel system now.

#60

Registered

Like they say keep it simple. I guess I was overthinking it. Makes sense now that you explained to me. The boost is a result of the fuel wouldn't make sense to try to control it by bleeding off boost. I wish it was that easy to play with the fuel map on the MB, problem is I doubt the transmission can handle much more torque.

Changing gears to the Yanmar 6LP my "map" is screws, springs, pins, and diaphragms. Do you know if this software (or similar) will work on any common rail marine diesels? Cummins 550, FPT 570, Yanmar 8LV 370, the Mercruiser 370 (I think still a VW motor), Steyr.

Changing gears to the Yanmar 6LP my "map" is screws, springs, pins, and diaphragms. Do you know if this software (or similar) will work on any common rail marine diesels? Cummins 550, FPT 570, Yanmar 8LV 370, the Mercruiser 370 (I think still a VW motor), Steyr.