Building a new engine hatch - any pointers?

#21

Registered

Thread Starter

iTrader: (3)

Join Date: Aug 2007

Location: Sandown, NH - Sebago Lake Region, ME

Posts: 2,960

Likes: 0

Received 7 Likes

on

7 Posts

Yes 2 layers of 1708 top & bottom........remember, I course of1708 is conprised of 17oz. bi-axle & 8oz. Mat.....so, in actuality it's 8 total layers of glass used. I can stand on it and it doesn't flex.

I've used Epoxy & 17 oz. bi-axle to glass the hull & deck together. It is a stronger resin, better sealer for wood, has better temperture tolerance and better strenght ratio with less glass. It is expensive and you don't need 1708 .....17oz. bi-axle alone would work the best.

I've used Epoxy & 17 oz. bi-axle to glass the hull & deck together. It is a stronger resin, better sealer for wood, has better temperture tolerance and better strenght ratio with less glass. It is expensive and you don't need 1708 .....17oz. bi-axle alone would work the best.

I really want to make sure it is nice and strong!!!

Thanks

Jim

#22

Platinum Member

iTrader: (3)

Join Date: Jan 2007

Location: Jackson, n.j. ~ Brooklyn, n.y.

Posts: 2,083

Received 151 Likes

on

77 Posts

For your hatch, the strongest application (I would use) is to match the best suggested glass with the proper resin. Hence, Epoxy resin/Bi-axle glass without mat....Vinylester resin/Bi-axle glass with mat.......I think these are the best combinations to use for laminating. Can you use epoxy & 1708?..........I think (like Dave said) in a pinch yes, but there's a definite reason to stick with the recomemded pairings......I remember something about the bindings in 1708 & using Epoxy isn't the best suited???........Dave???

#23

Jim,

For your hatch, the strongest application (I would use) is to match the best suggested glass with the proper resin. Hence, Epoxy resin/Bi-axle glass without mat....Vinylester resin/Bi-axle glass with mat.......I think these are the best combinations to use for laminating. Can you use epoxy & 1708?..........I think (like Dave said) in a pinch yes, but there's a definite reason to stick with the recomemded pairings......I remember something about the bindings in 1708 & using Epoxy isn't the best suited???........Dave???

For your hatch, the strongest application (I would use) is to match the best suggested glass with the proper resin. Hence, Epoxy resin/Bi-axle glass without mat....Vinylester resin/Bi-axle glass with mat.......I think these are the best combinations to use for laminating. Can you use epoxy & 1708?..........I think (like Dave said) in a pinch yes, but there's a definite reason to stick with the recomemded pairings......I remember something about the bindings in 1708 & using Epoxy isn't the best suited???........Dave???

__________________

Throttles- Cleveland Construction 377 Talon

08 OPA Class 1 National Champion

08 Class 1 Geico Triple Crown Champion

08 OPA High Points Champion

10 OPA Class 1 National Champion ( happy now Ed! )

Throttles- Cleveland Construction 377 Talon

08 OPA Class 1 National Champion

08 Class 1 Geico Triple Crown Champion

08 OPA High Points Champion

10 OPA Class 1 National Champion ( happy now Ed! )

#24

Registered

Thread Starter

iTrader: (3)

Join Date: Aug 2007

Location: Sandown, NH - Sebago Lake Region, ME

Posts: 2,960

Likes: 0

Received 7 Likes

on

7 Posts

All my materials have arrived and all the prep work is done to the wood. The next step is to fiberglass it! Any final pointers??

The glassing starts tomorrow!

The glassing starts tomorrow!

#25

Registered

Thread Starter

iTrader: (3)

Join Date: Aug 2007

Location: Sandown, NH - Sebago Lake Region, ME

Posts: 2,960

Likes: 0

Received 7 Likes

on

7 Posts

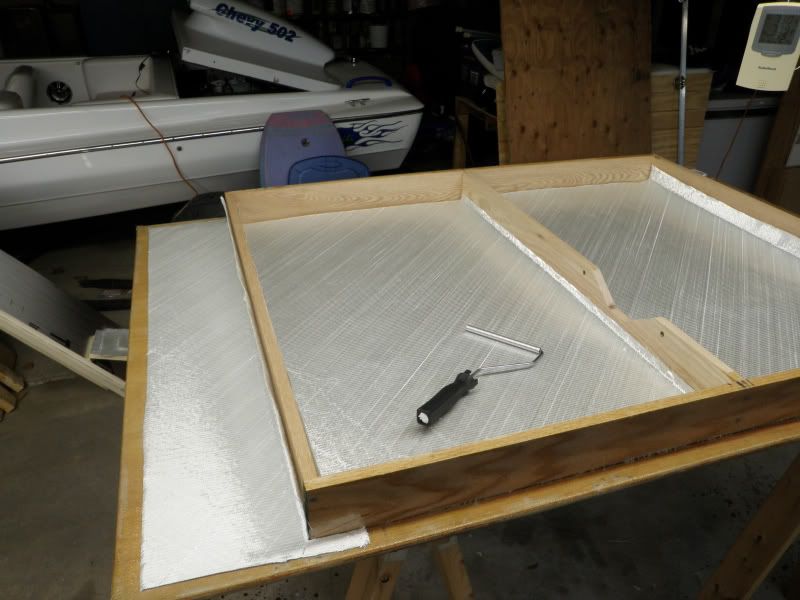

Top side is done! Tonight or tomorrow I will do the bottom. It was tricky to get the glass to wrap around the edge of the board and stick to the bottom. I had resin running down my arms from working upside down! What a mess but I am happy with the results so far!

#27

Platinum Member

iTrader: (3)

Join Date: Jan 2007

Location: Jackson, n.j. ~ Brooklyn, n.y.

Posts: 2,083

Received 151 Likes

on

77 Posts

Jim,

Why does the box frame (you built on top of ply sheet) not extend out to the corners of the plywood?...........Also, if you haven't already, fillet all the corners with a hull & deck putty. 1708 doesn't like sharp bends..........looks like you making good progress......nice job!

Why does the box frame (you built on top of ply sheet) not extend out to the corners of the plywood?...........Also, if you haven't already, fillet all the corners with a hull & deck putty. 1708 doesn't like sharp bends..........looks like you making good progress......nice job!

#28

Registered

Thread Starter

iTrader: (3)

Join Date: Aug 2007

Location: Sandown, NH - Sebago Lake Region, ME

Posts: 2,960

Likes: 0

Received 7 Likes

on

7 Posts

Jim,

Why does the box frame (you built on top of ply sheet) not extend out to the corners of the plywood?...........Also, if you haven't already, fillet all the corners with a hull & deck putty. 1708 doesn't like sharp bends..........looks like you making good progress......nice job!

Why does the box frame (you built on top of ply sheet) not extend out to the corners of the plywood?...........Also, if you haven't already, fillet all the corners with a hull & deck putty. 1708 doesn't like sharp bends..........looks like you making good progress......nice job!

The 1708 did very well in the tight corners. It helped to have the right rollers. I bought the corner roller and the small roller used to remove air bubbles. Huge difference!!

We tested the strength today. Had it supported just along the two edges and had me and my buddy (close to 400lbs) stand on the cover and it didn't move at all!

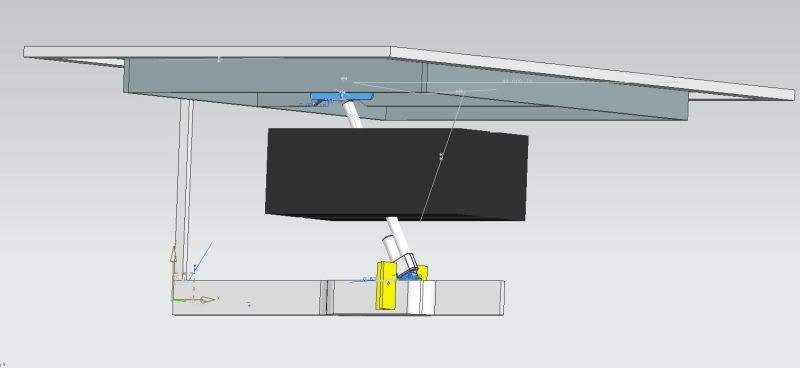

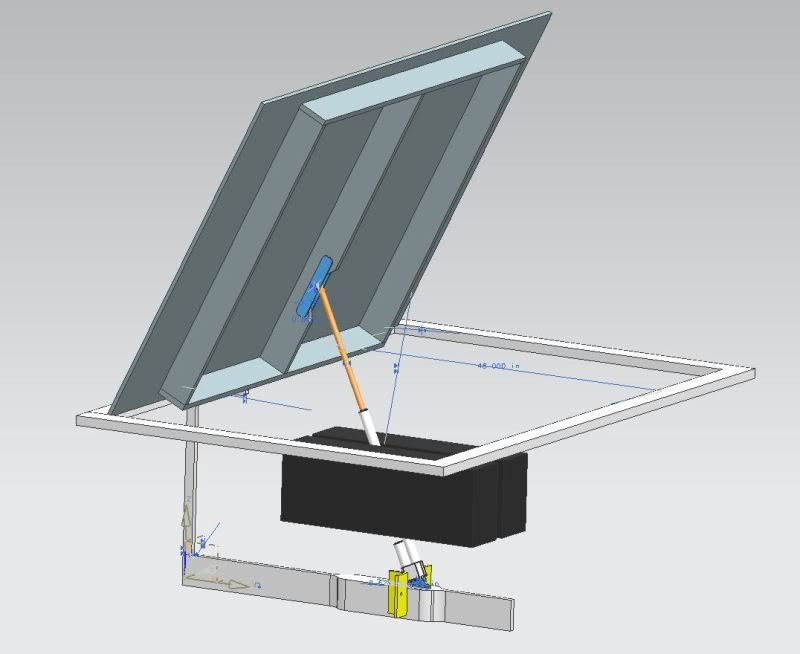

The reason the box doesn't go out to the edge of the plywood is because of interference with the manifold risers. The vertical box will land just to the inside of the outside risers directly over the valve covers. (see picture below)

My next question is what do I paint it with? Top side is not that important because it will be totally covered with a hatch pad but the bottom side needs to look good! I am thinking either awlgrip or actual gelcoat!

Any thoughts??

#29

Registered

iTrader: (4)

Looking good! What are you going to use for the hatch ram? and where do you plan on placing it? If you need some pics I have some for ram placement if you use a single ram in the middle. We have pretty much the same setup.

#30

Registered

Thread Starter

iTrader: (3)

Join Date: Aug 2007

Location: Sandown, NH - Sebago Lake Region, ME

Posts: 2,960

Likes: 0

Received 7 Likes

on

7 Posts

I have spent many hours in my CAD software playing with different ram mounting options. I have settled on mounting it on the center stringer right between the engines. I am going to push on the cover were the recess is on the center support beam. You can see it in one of the earlier posts and in the CAD renderings. Where are you pushing yours from?