Bearings - dirt or oil starvation - need expert opinions, please

#1

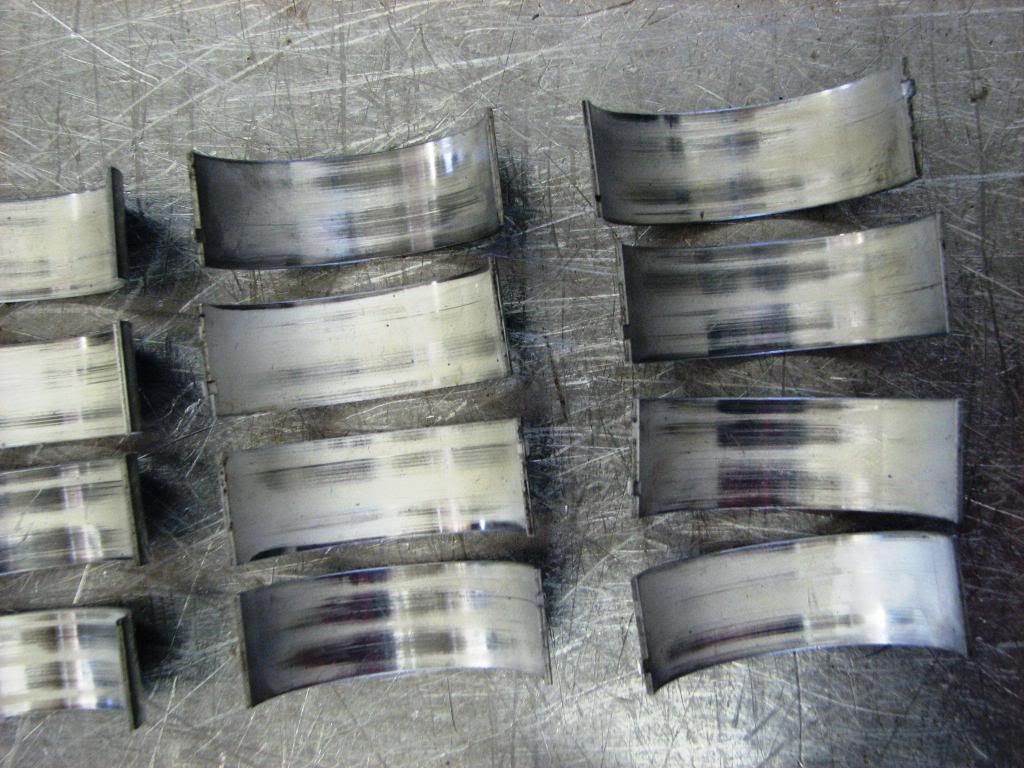

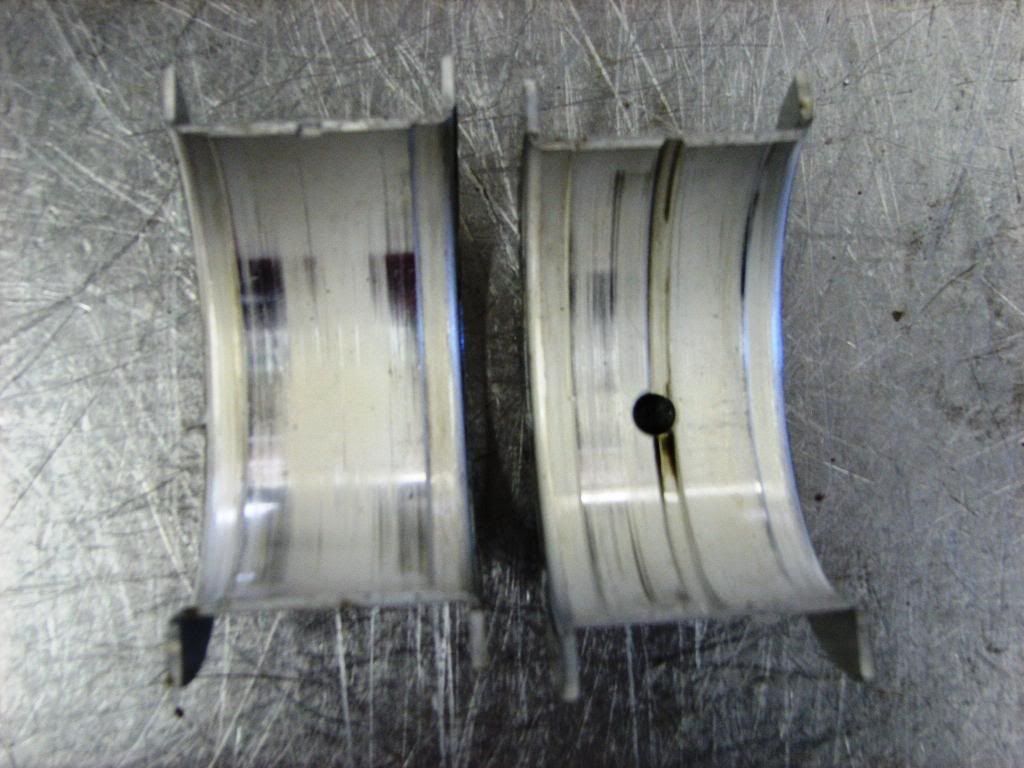

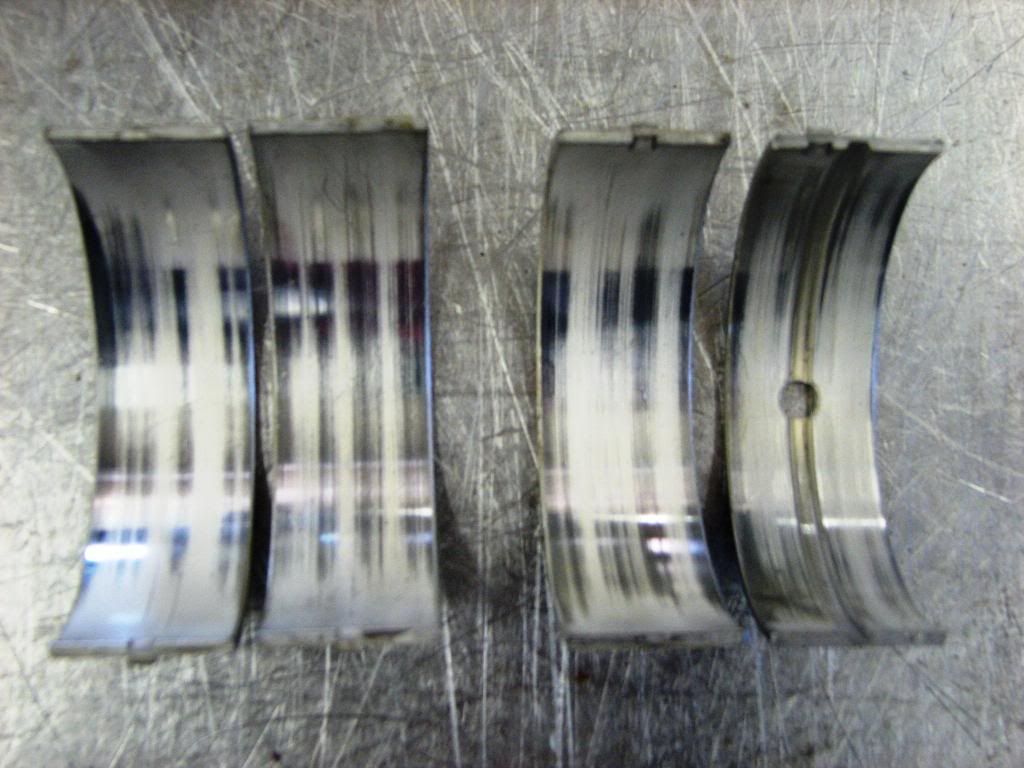

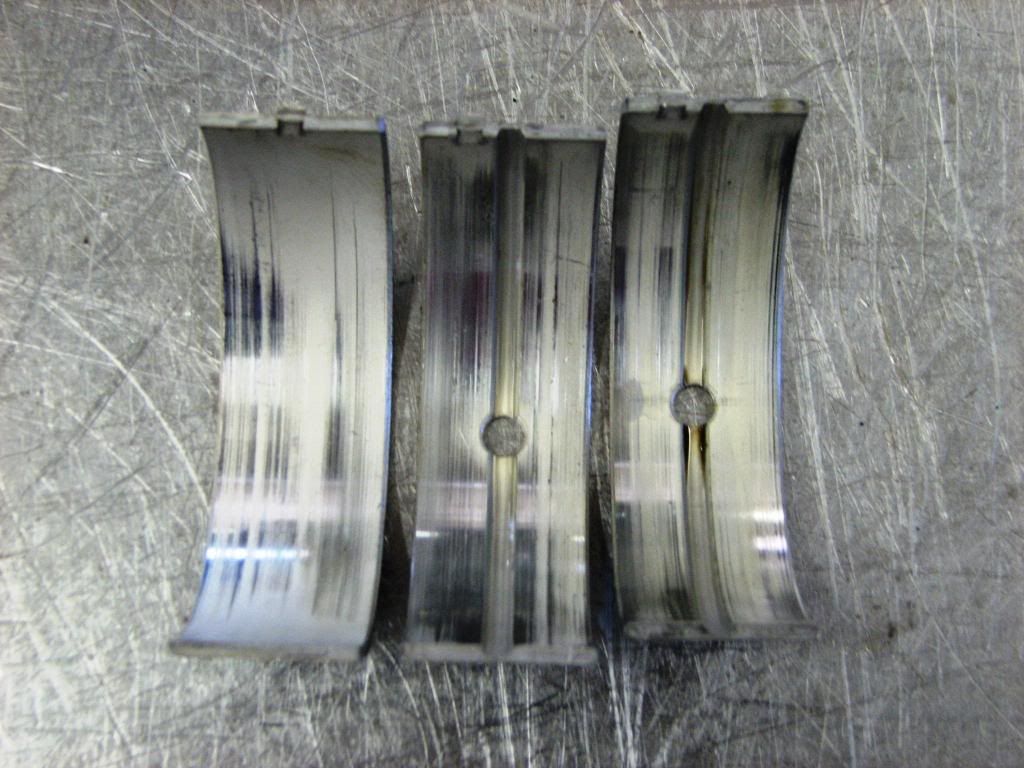

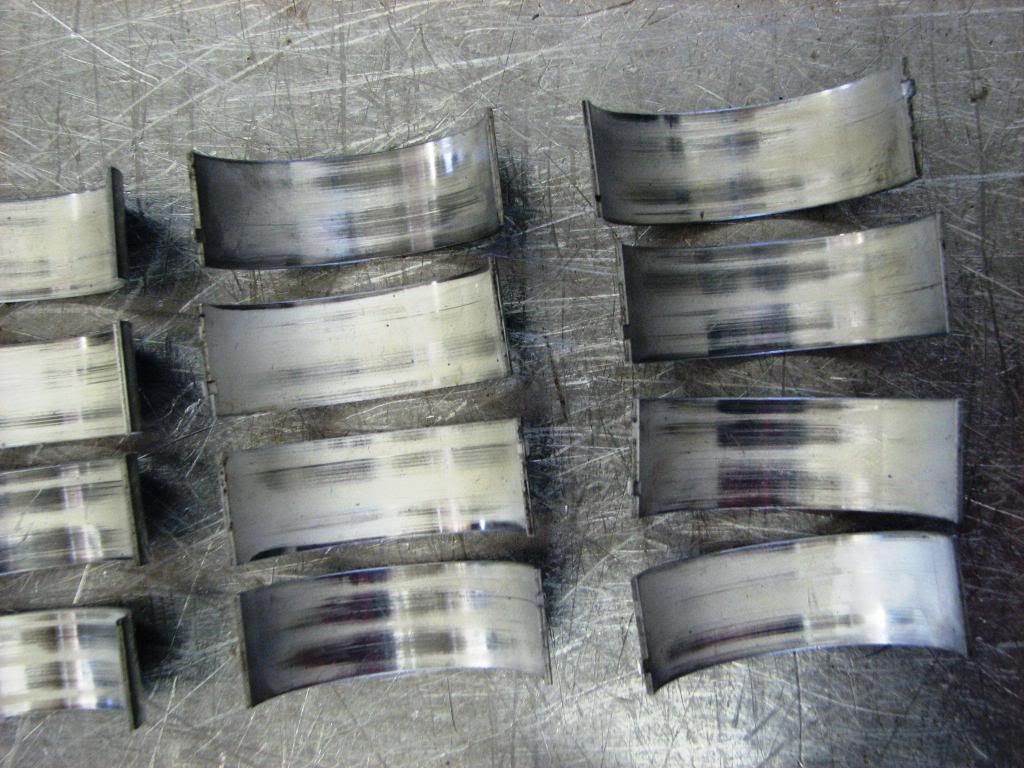

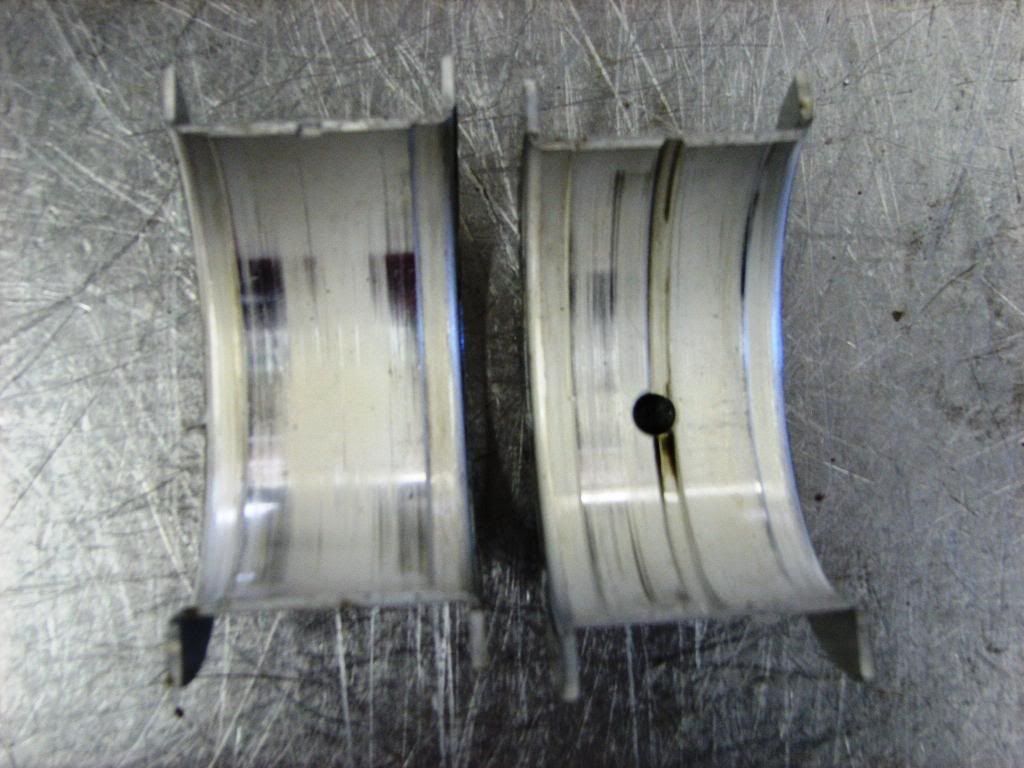

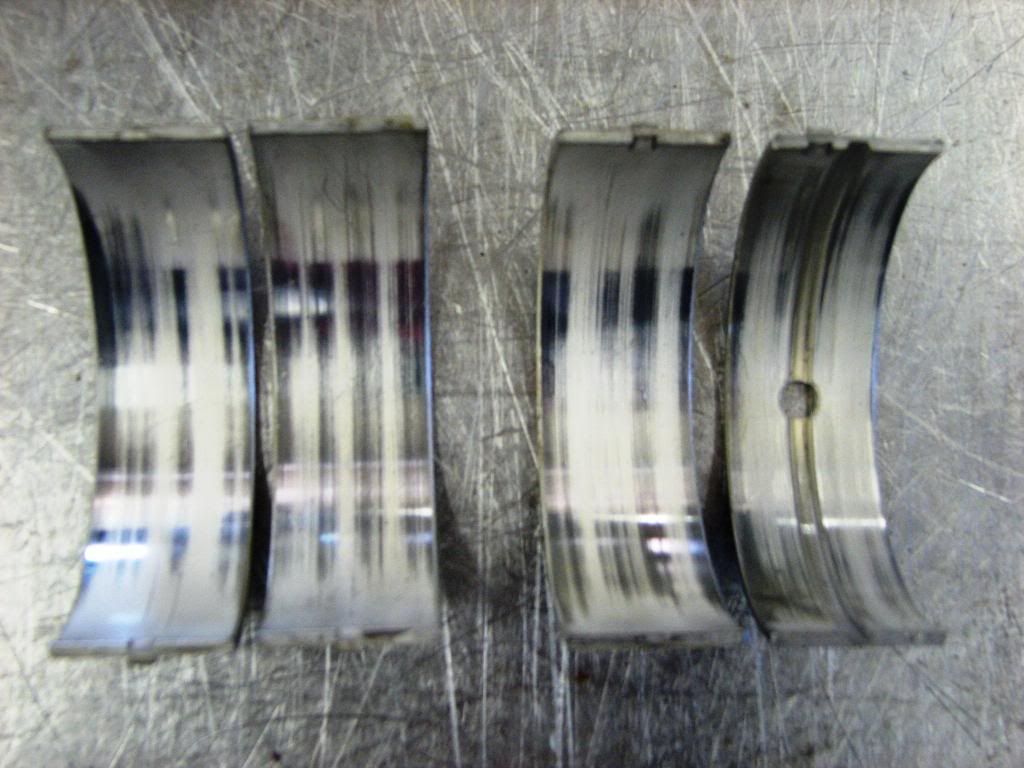

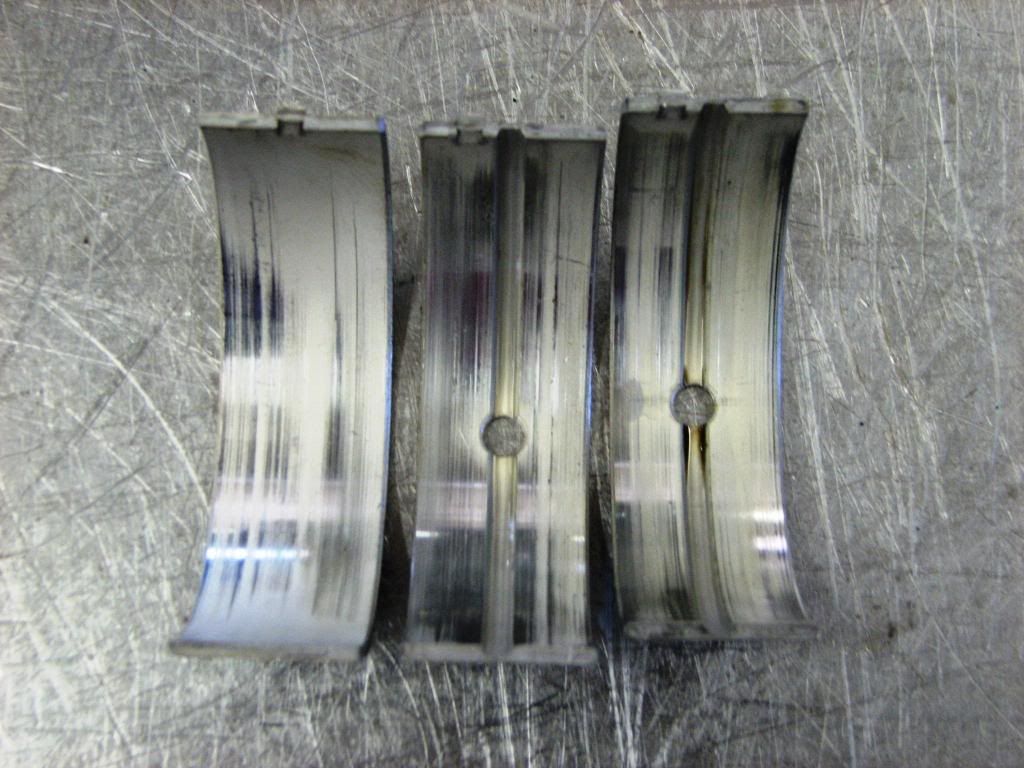

I have a couple of other threads related to the demise of my 489 floating around on here, but I thought this one should be split out into its own thread. These are the bearings from my 489 BBC. I had 5 exhaust lobes with severe spalling on my hyd roller cam, and some wear on the distributor gear. My first thought on examining these bearings was that this was the result of metal fragments from that damage going through the bearings, but after looking at pictures of damaged bearings on the Clevite site - http://catalog.mahleclevite.com/bearing/ - I am becoming concerned that I may have an additional oil starvation or cold start issue. None of the marks on these bearings were deep enough to feel with your fingertips. I had some minor scuffing on my piston skirts too, so some metal definitely went through the motor. I never did see low oil pressure while running it, and oil temps were running about 180* under light load and around 225* on a hard run. I was running 20W50 conventional oil.

I would appreciate some comments from some of the pros on here as to whether this wear is the result of fine particles, or if it is evidence of lack of oil film at the bearings.

Thanks!

I would appreciate some comments from some of the pros on here as to whether this wear is the result of fine particles, or if it is evidence of lack of oil film at the bearings.

Thanks!

#2

Registered

Join Date: Mar 2008

Location: Vancouver BC

Posts: 1,181

Likes: 0

Received 0 Likes

on

0 Posts

Just a guess but, it looks like incorrect clearances, a bit of bad machining, and a hint of detonation for good measure... I haven't read your other thread but, if you're having the engine rebuilt, then definitely get the main bore checked for alignment, and the big end size on the rods. Also wouldn't hurt to have the crank checked for size and straightness. If you had oil issues you'd see heat on the crank, rods, etc., and usually more damage to the bearings. #1 should be the worst as it's the last in line for oil. It looks like some particles may have gone through there too but, that isn't what's causing the uneven shiny areas. That stuff should have been caught during assembly.

#3

Registered

iTrader: (2)

Join Date: Aug 2005

Location: Between A Womans Leggs in IL

Posts: 6,306

Likes: 0

Received 1 Like

on

1 Post

I'm taking the 5th on this one..Seem's a few certain members bash my comments so ill keep to my self even tho thease bearing look like the ones i took out of a engine...

#5

Registered

Was that crank new? I hate to say it but I've heard a lot of bad stories about Eagle cranks. Like specs being all over the place as well as tapered journals and out of round. Don't know how close your builder checked everything but those cranks need to be checked close and set up carefully. Believe it or not a lot of people have the thinking of new crank-new bearings-everything must be fine.

You can do a search on the web of Eagle Crank Problems and read about these things. I think there has even been a lot of problems mentioned on this board.

You can do a search on the web of Eagle Crank Problems and read about these things. I think there has even been a lot of problems mentioned on this board.

#6

Registered

iTrader: (2)

Join Date: Aug 2005

Location: Between A Womans Leggs in IL

Posts: 6,306

Likes: 0

Received 1 Like

on

1 Post

Was that crank new? I hate to say it but I've heard a lot of bad stories about Eagle cranks. Like specs being all over the place as well as tapered journals and out of round. Don't know how close your builder checked everything but those cranks need to be checked close and set up carefully. Believe it or not a lot of people have the thinking of new crank-new bearings-everything must be fine.

You can do a search on the web of Eagle Crank Problems and read about these things. I think there has even been a lot of problems mentioned on this board.

You can do a search on the web of Eagle Crank Problems and read about these things. I think there has even been a lot of problems mentioned on this board.

#7

Thanks for the input guys - I would agree that the tolerances on the crank could be suspect, and other machining issues could be the cause, but the builder is pretty meticulous, so I would be surprised if these areas were not checked. I paid extra to have the mains align honed, because they were just slightly out. I didn't check the clearances myself, so I guess I am just relying on the word of the machinist at this point. I will be assembling the bottom end myself this time, so I will be extra careful about checking tolerances this time.

FWIW, when I dropped the crank off with him to have it polished last week, he checked the main and rod journals for size and consistency, and nothing out of the ordinary was noted.

I seriously doubt detonation was an issue. I was only running about 8.6:1 on Mahle forged flat tops, and the tune was a bit on the rich side to begin with. Total timing was set conservatively at 32*. Was running 91 - 93 octane. I did note relatively high cranking compression numbers when I checked before teardown - 185+ PSI, but the cam didn't have a lot of overlap to bleed off pressure.

Bob M's reply on my other thread got me thinking about the possibility of oil starvation due to too cold and too thick oil running through the engine. That is why I am taking a close look at my oil supply system this time.

Thanks for the input. More is welcome.

FWIW, when I dropped the crank off with him to have it polished last week, he checked the main and rod journals for size and consistency, and nothing out of the ordinary was noted.

I seriously doubt detonation was an issue. I was only running about 8.6:1 on Mahle forged flat tops, and the tune was a bit on the rich side to begin with. Total timing was set conservatively at 32*. Was running 91 - 93 octane. I did note relatively high cranking compression numbers when I checked before teardown - 185+ PSI, but the cam didn't have a lot of overlap to bleed off pressure.

Bob M's reply on my other thread got me thinking about the possibility of oil starvation due to too cold and too thick oil running through the engine. That is why I am taking a close look at my oil supply system this time.

Thanks for the input. More is welcome.

#8

I'll try to get some pictures of the pistons, but they had obvious signs of scuffing from foreign material on the skirts, with some imbedded particles. Not bad enough not to run again, but I will have to burnish the skirts a little bit to make sure not particles are still there. Piston crowns looked good, although a bit carboned from running fat.

#10

Registered

iTrader: (3)

budman,i am not saying this is what happened,and i doubt any shop would assemble an engine without lubricating the bearings ,but stranger things have happened.if this is the case,i could see where the bearings would look shiny from contact with the crank as the crank is turned during assembly,then you primed it before initial start up.if you run your finger nail across the bearing, does it feel smooth,or can you feel any roughness.i once had a guy,oso member,tell me prelubing the bearings was not necessary,because they would get oil during priming,that is a scary thought.