40' Outlaw Upgrades - Twin 900Sc to 1000hp Duramax Diesels

#311

Registered

Thread Starter

Currently around 54.5" off transom if I recall. With a +2.5deg jacked angle, if boat ran flat at 60mph, no prop would be in water...

#312

Registered

Thread Starter

This has turned out to be a real pain in the hatch, but we finally have the glass setting correctly.

After laser cutting multiple cardboard templates to within 3mm edge tolerance, and clearly specifying the glass panels ONLY be waterjet cut for accuracy, all that got lost in translation. Glass was hand cut and ended up being 1/2" out of specs in several spots. Then I learned once tempered, ya can't grind the edges of glass to make it fit. But all that didn't stop the glass shop from installing them incorrectly soon as I left.. I go to pick it up and find the front corners setting higher than the center fiberglass [first pic] right where your gonna step on it every day...

Luckily a fiend of a friend is really good at fixing others install screw ups. Wire cut both panels out, and after little tweaking to the hatch, have both panels sitting pretty flush. All good now, and back to what I was working on before leaning how to be a glass installer.

After laser cutting multiple cardboard templates to within 3mm edge tolerance, and clearly specifying the glass panels ONLY be waterjet cut for accuracy, all that got lost in translation. Glass was hand cut and ended up being 1/2" out of specs in several spots. Then I learned once tempered, ya can't grind the edges of glass to make it fit. But all that didn't stop the glass shop from installing them incorrectly soon as I left.. I go to pick it up and find the front corners setting higher than the center fiberglass [first pic] right where your gonna step on it every day...

Luckily a fiend of a friend is really good at fixing others install screw ups. Wire cut both panels out, and after little tweaking to the hatch, have both panels sitting pretty flush. All good now, and back to what I was working on before leaning how to be a glass installer.

#314

Gold Member

He said "mm". (millimeter)

If anyone's wondering, 3 mm is really small, it's about a pfteenth of an inch.

Nice work Kidturbo, not just the mechanical design and engineering but the attention to detail with cosmetic items will really pay off. The finished product is gonna be beautiful.

RR.

If anyone's wondering, 3 mm is really small, it's about a pfteenth of an inch.

Nice work Kidturbo, not just the mechanical design and engineering but the attention to detail with cosmetic items will really pay off. The finished product is gonna be beautiful.

RR.

#315

Registered

Thread Starter

#316

Registered

The world would greatly benefit if we’d all adopt the C hair unit of measurement. Very fine unit of measurement. I think issues like this could be avoided. There’s several different sizes- blk C hair, Blnd C hair, brn C hair, and the very rare R C hair.

Definitely one of the coolest projects to follow along with. Keep it up!

Definitely one of the coolest projects to follow along with. Keep it up!

#319

Registered

Thread Starter

Thanks guys.

BR I bet your buddy doesn't have to walk on his house windows either.. Imagine stubbing your toe on a 1/4" high glass corner, [cause obviously be in bare feet] then ya trip and fall on one of those tempered plates.

Yesterday I sent the the shop owner pictures of where the glass measured out of spec by 1/2", along with how much I paid to have them reset. Ask for a couple hundred refund on the CC since the glass obviously wasn't as ordered, but the other guy still made it fit. He basically told me to piss off and don't contact him again. So maybe I'll share his cell # with a couple of these aholes who call me up every day offering 50k in business funding...

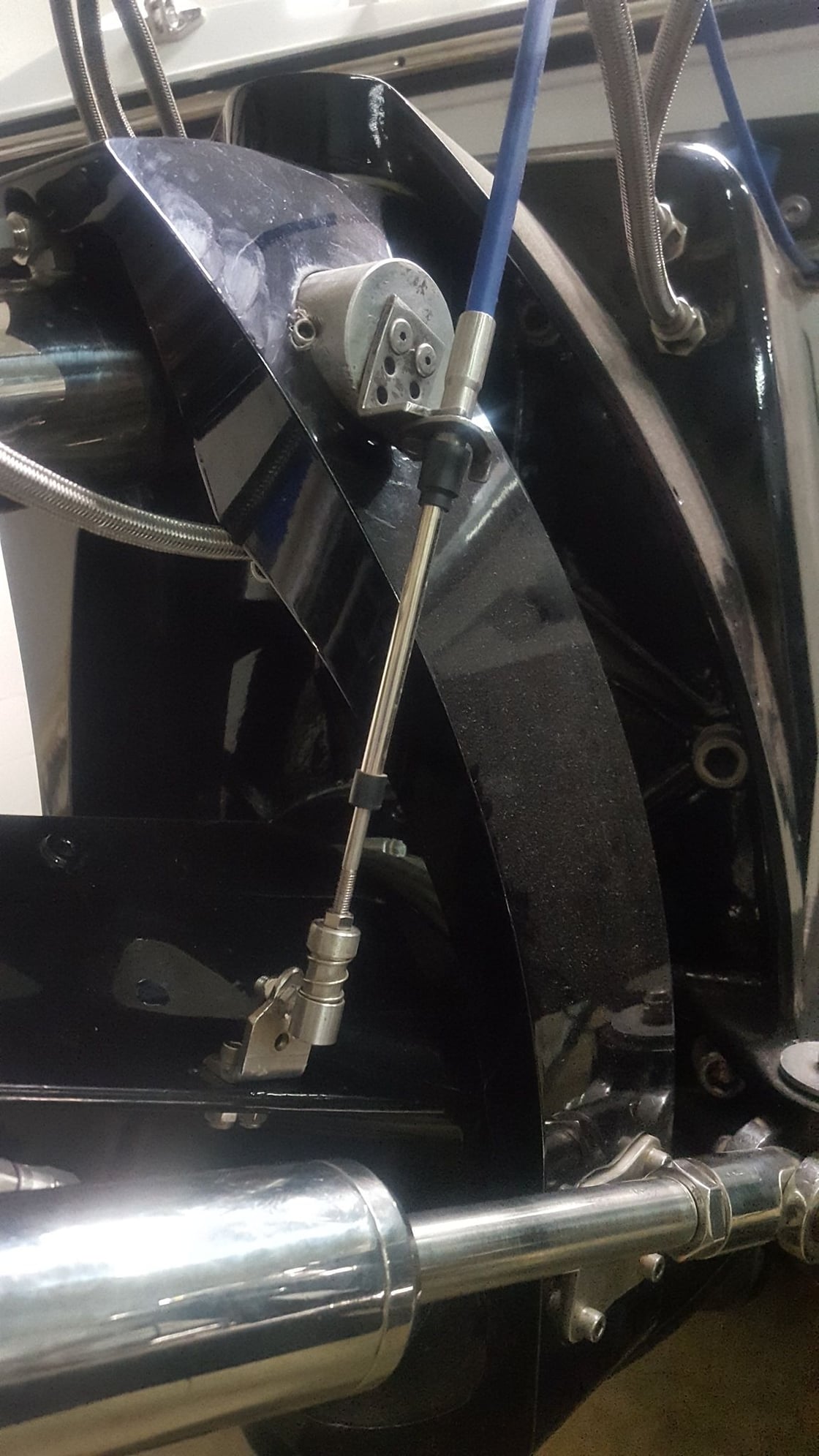

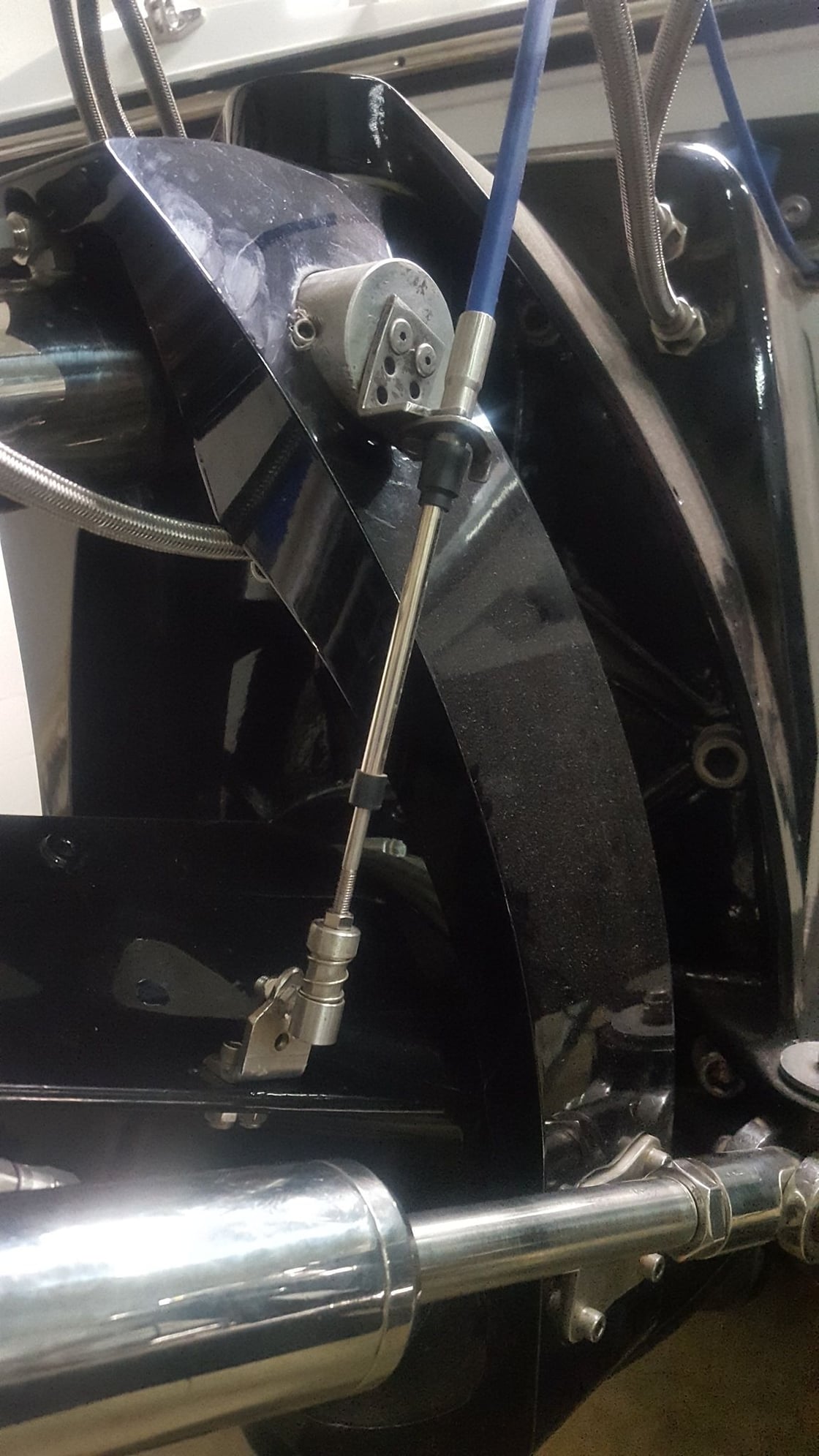

Now back to adjusting these digital drive trim indicators to within 0.1deg of each other. JUST BECAUSE I CAN !!

BR I bet your buddy doesn't have to walk on his house windows either.. Imagine stubbing your toe on a 1/4" high glass corner, [cause obviously be in bare feet] then ya trip and fall on one of those tempered plates.

Yesterday I sent the the shop owner pictures of where the glass measured out of spec by 1/2", along with how much I paid to have them reset. Ask for a couple hundred refund on the CC since the glass obviously wasn't as ordered, but the other guy still made it fit. He basically told me to piss off and don't contact him again. So maybe I'll share his cell # with a couple of these aholes who call me up every day offering 50k in business funding...

Now back to adjusting these digital drive trim indicators to within 0.1deg of each other. JUST BECAUSE I CAN !!

Last edited by kidturbo; 05-30-2019 at 10:33 PM.

#320

Registered

Post his name, business name and cell phone.....****wit he is.