40' Outlaw Upgrades - Twin 900Sc to 1000hp Duramax Diesels

#391

Registered

Thread Starter

Most simply, there would be no easy way to get at the flange bolts. But adding a simple removable stainless safety shield over these main loops is actually on my list of things.. Main design concern was loops strong enough to cradle and capture the drive shaft if a U-Joint fails at speed on transmission end.

#393

Registered

Thread Starter

Exhaust pipes are done, polished, and ready to bolt on.

40' Outlaw Upgrades - Twin 900Sc to 1000hp Duramax Diesels

Last thing that gets bolted on, cause they take up all the room behind turbos.

40' Outlaw Upgrades - Twin 900Sc to 1000hp Duramax Diesels

Last thing that gets bolted on, cause they take up all the room behind turbos.

#396

Registered

Thread Starter

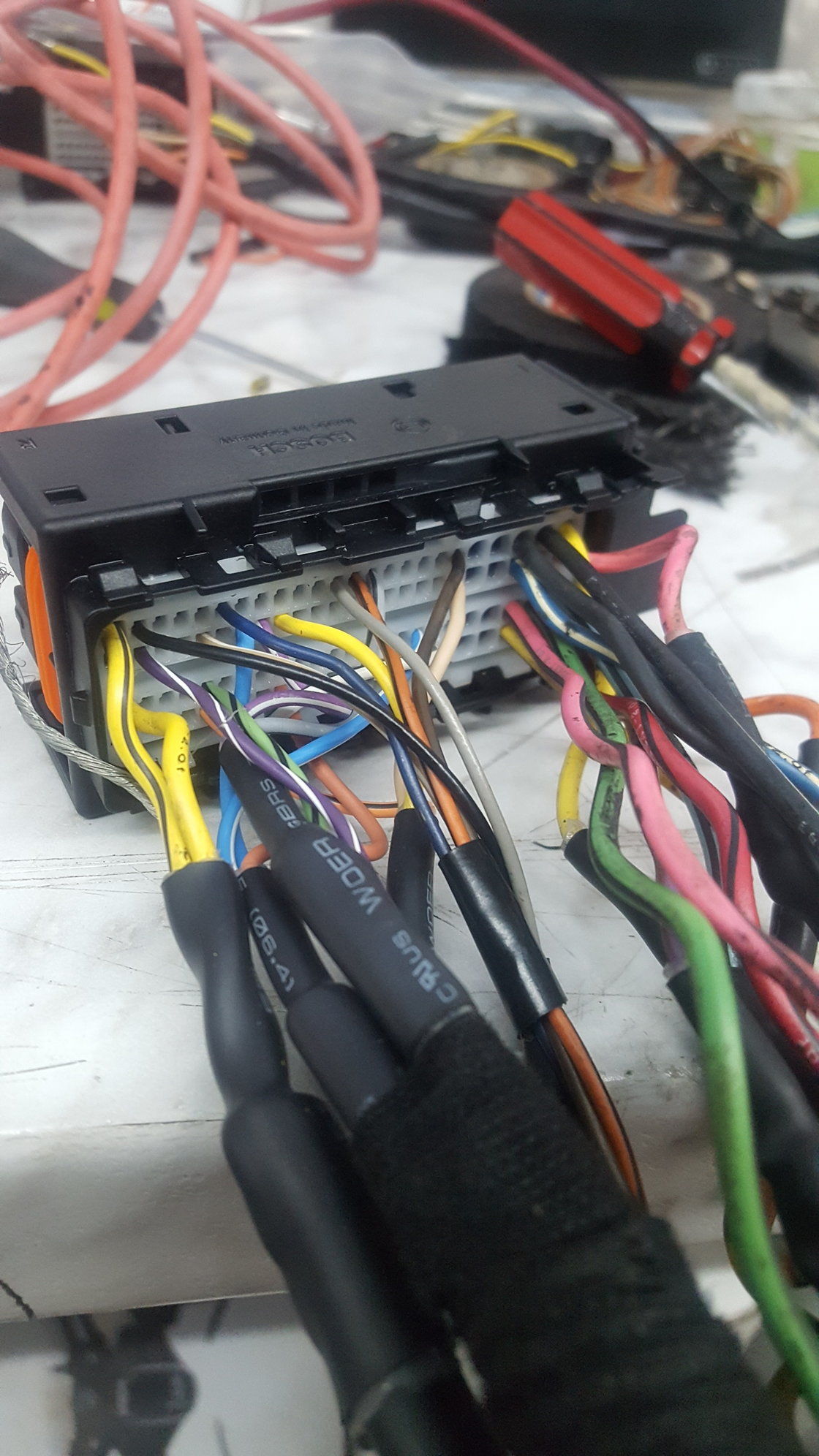

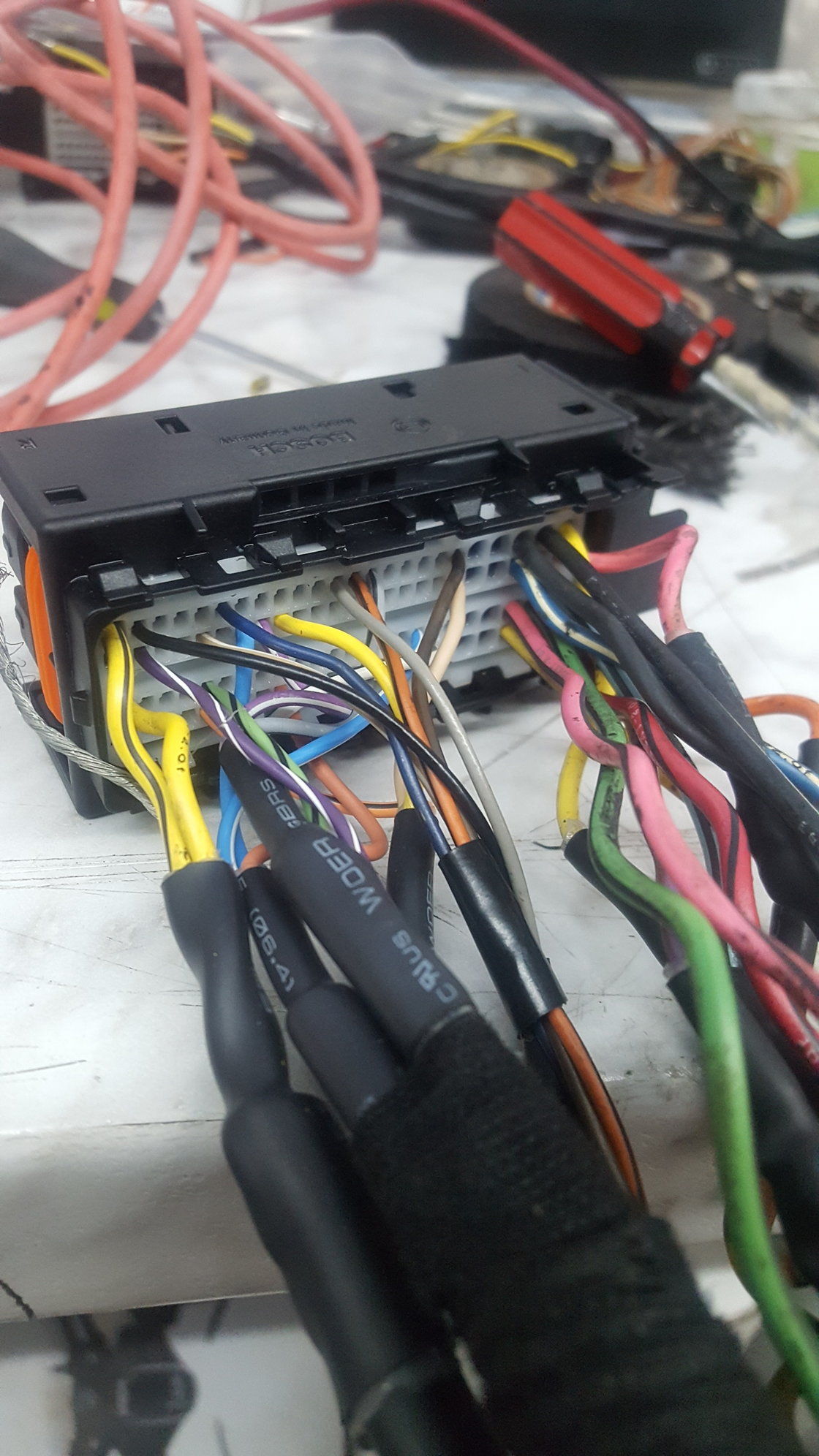

Once I get all this electrical stuff connected up, they could be running in a couple days.

Fuel system is coming together nicely. We had to pull the extra pickup tubes outa the tank to make room for the diesel fuel returns. But as of last week, everything has oil in it, and we even found some things to spin...

Fuel system is coming together nicely. We had to pull the extra pickup tubes outa the tank to make room for the diesel fuel returns. But as of last week, everything has oil in it, and we even found some things to spin...

#397

Registered

Thread Starter

All the aluminum helm pieces showed up from local waterjet shop last week. A little dash trimming and fitting, but should head off to powedercoating later this week.

As always, some assembly required :-)

As always, some assembly required :-)

Last edited by kidturbo; 08-12-2019 at 05:24 AM.

#399

Registered

Thread Starter

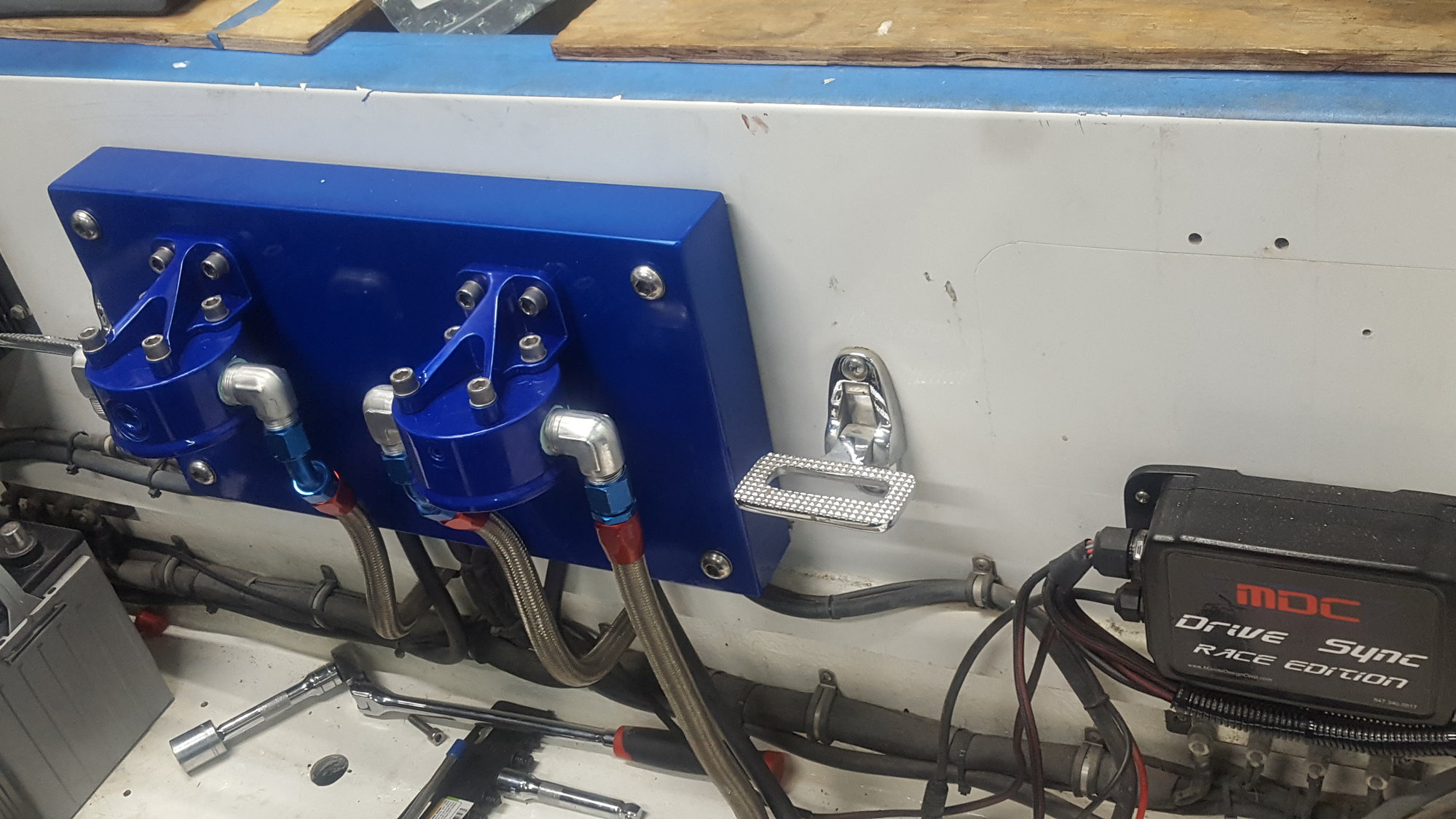

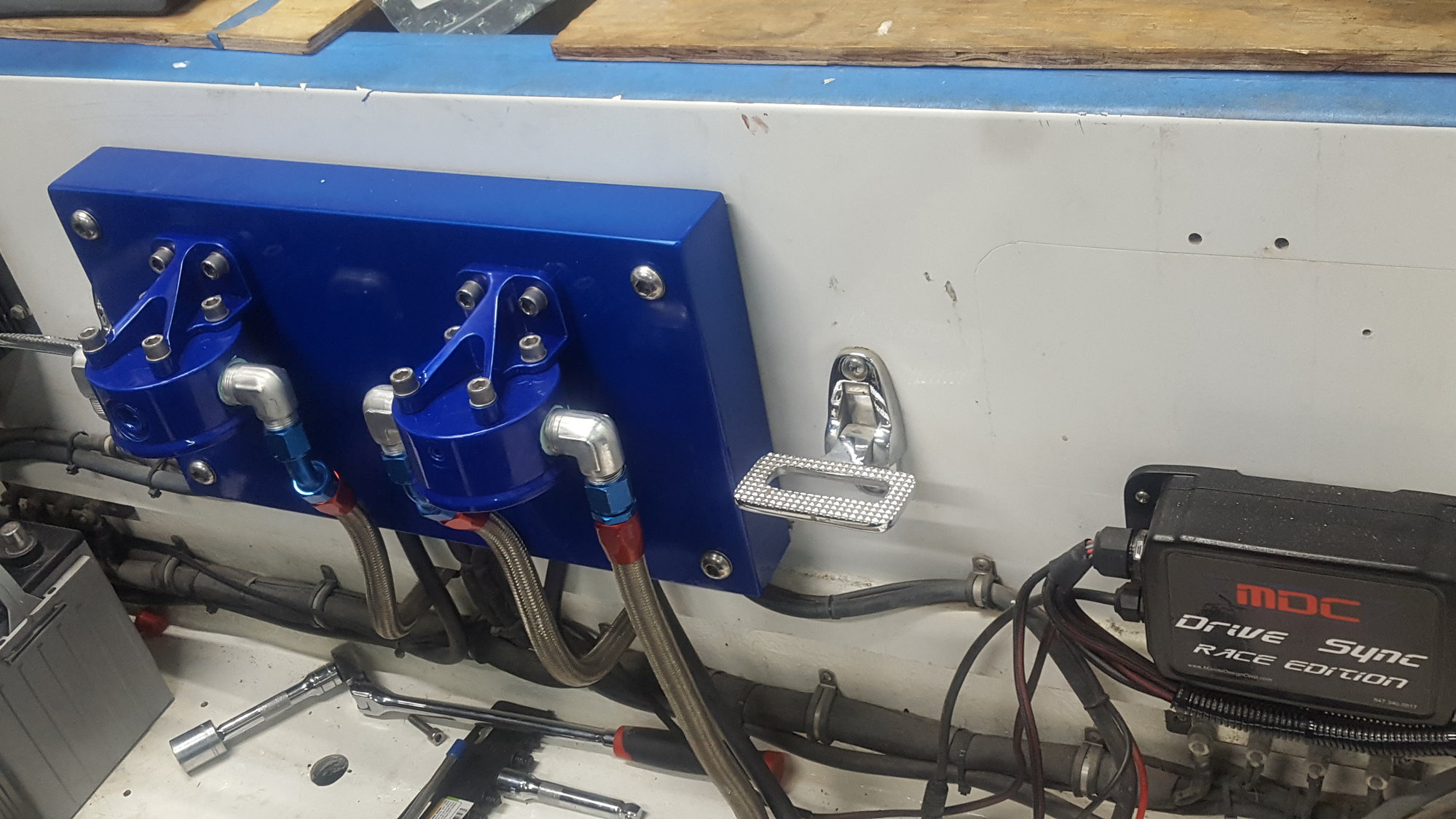

The CP3 mechanical lift can actually suck through if it fails to spin up. Running the same 15micron water separators that came with the 900's. Then after the lift pump, under the crank pulley is a 1-micron glass filter before reaches the CP3. Also have the lift hooked to an old school oil pressure switch, so it doesn't kick on until engine fires up. Engine dies,automatically kicks off.

#400

Registered

Thread Starter

Speaking of those Weismanns,, do ya recall what direction your turbines output shafts spun??

Reason I ask, we fired up port side engine last week. With driveshaft spinning clockwise, everything looking great, except I'm get no oil pumping outa the upper gear set. So I overfilled the pan and primed it with air pressure. Crank it over again, and noticed it's sucking in on the out port.. Only reasonable explanation, pump is clocked backwards. And I'd thought those were bi-directional, so never checked the flow, just plumbed em back up as they were on the Nor-Tech.

So tonight I stop by the shop and grabbed one of the spare pumps to crack open. And quickly find they are a not bi-directional design like the lower units. And I'm betting those turbines spin counter clockwise...

Looks like I'll be pulling "two" driveshafts next week and spinning both pumps around. Besides that, things were coming together quite nicely. Luckily we caught it before bolting up all the exhaust. Here is picture of those pumps, if anyone recognizes the design, please chime in.

Reason I ask, we fired up port side engine last week. With driveshaft spinning clockwise, everything looking great, except I'm get no oil pumping outa the upper gear set. So I overfilled the pan and primed it with air pressure. Crank it over again, and noticed it's sucking in on the out port.. Only reasonable explanation, pump is clocked backwards. And I'd thought those were bi-directional, so never checked the flow, just plumbed em back up as they were on the Nor-Tech.

So tonight I stop by the shop and grabbed one of the spare pumps to crack open. And quickly find they are a not bi-directional design like the lower units. And I'm betting those turbines spin counter clockwise...

Looks like I'll be pulling "two" driveshafts next week and spinning both pumps around. Besides that, things were coming together quite nicely. Luckily we caught it before bolting up all the exhaust. Here is picture of those pumps, if anyone recognizes the design, please chime in.