1979 24 pantera se restoration/class 6 build

#1

Bought this 1979 24 pantera last year 454 trs boat. Bought it sight unseen shipped it from washington state to NJ. Turned out the 454 was locked up so i tore it out and threw an LS in it. Kicked cam bearings out of the first stock 6.0 then threw a 700hp blower motor in it kicked the cam bearings out of that one too (needed a bigger sump) so i decided to tear into it and bravo swap it. Well once i cut into the transom there was no turning back and it has spiraled into building a class 6 boat lol theres a ton of work to be done but I am determined to race it this year. Figured i would post the progress on here for anyone interested

The following users liked this post:

hogie roll (04-08-2024)

#3

Pulled the 454 out inspected stringers/transom with a hammer and meter was surprisingly not rotted (little wet on meter but not in the red)

Sanded engine room down painted with some bilgecoat. I remember doing this thinking man this is alot of work HA!

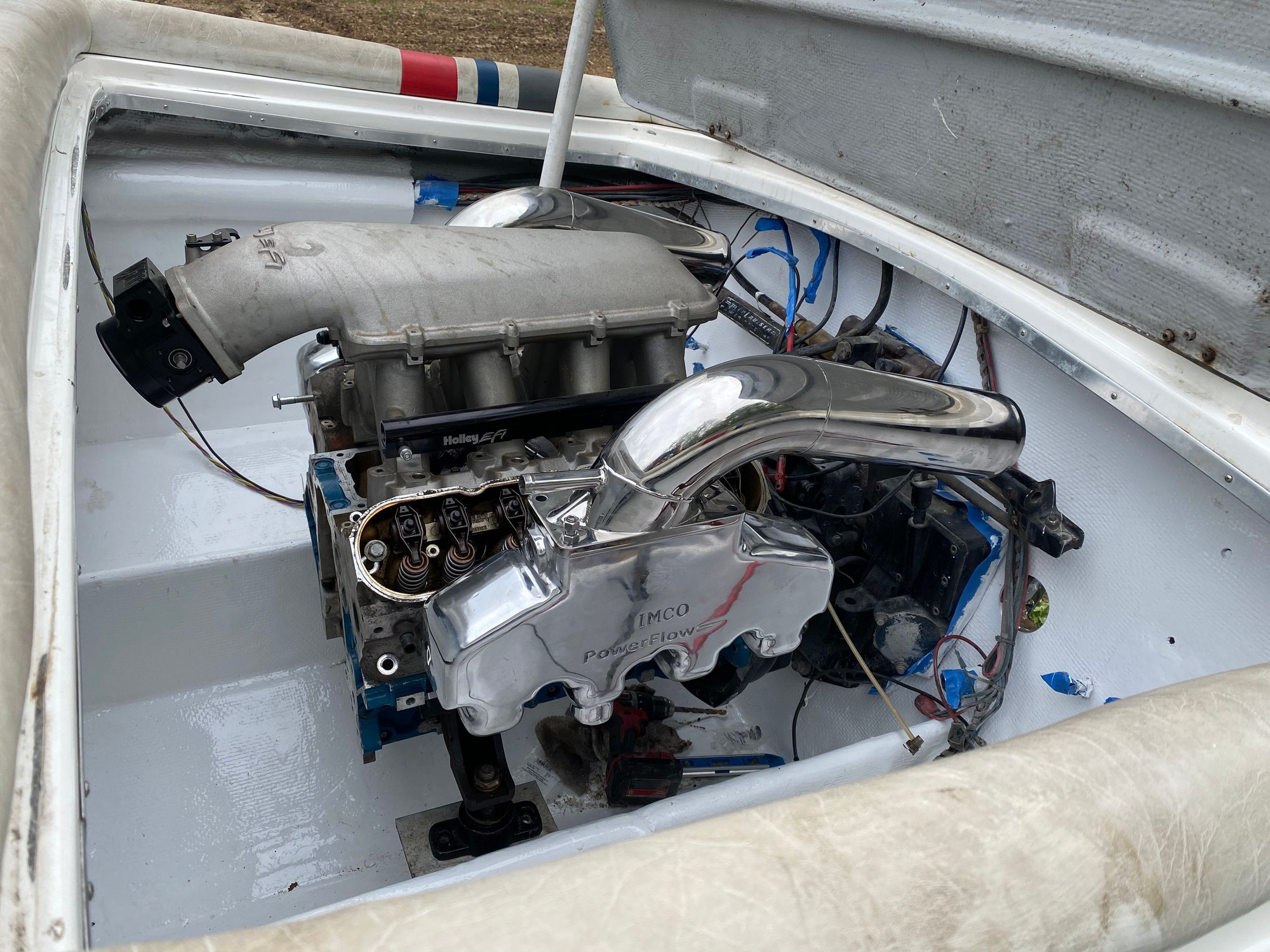

Mocked up an ls in it with some imco powerflows

Wet sanded it to see how it would come up. Hull bottom was all nicked up with gelcoat failing knew that id have to recoat it but hullsides came up good.

#4

Drilled new exhaust holes for the LS

Filled in the old exhaust holes and painted the transom outside in 100 degree weather.

Finally got it running and in the water to tune it. With the bone stock LS with a cam we saw 60 out of it running like complete crap up top. Then it kicked the bearings out

At this point i bought my 28 and the 24 got sidelined for a bit

#5

Ran the 28 all summer and labor day we blew the drive apart. Full send snout blown apart and all. So then it was back to the 24 while we waited for the imco scx.

Decided to pull the lsa blower motor out of my c10 and show up to the boat ramp the next weekend and not tell my friends what was in the boat. They were all very surprised lol

Blew the cam bearings out of the lsa set up but the boat never saw wide open throttle but was scary fast. So decided to strip it down and see what i could do with the hill

The original plan was to step around the hole and put some wood in and cut for a bravo keep it simple but i decided to rip it all out and good thing i did.

The outsides of the transom definetely had moisture at some point

The following users liked this post:

resurrected (04-10-2024)

#6

Cut stringers back to get new wood in. Theyre surpisingly really dry. Cut the battery box out also.

Started ripping the cabin apart to add to the dumpster before putting it inside

All torn out

Windshield was removed. Cant have glass to race so were going to a fiberglass fairing.

Cutting the backseat out to get the tank removed

Tank pulled. Never leaked but glad i did it because it was realllll close to leaking

Sanded down and prepped for new wood

Used 2 3/4” marine ply pieces and sandwiched them together with CSM

Doug templating the transom wood. At this point we knew there was no turning back

New wood installed

#7

Transom and stringers in and glassed on the inside. 3 layers of 1708 with tabbing and ve resin. Definitely a learning curve i have never done any glass work before let alone cut a boat apart this far. This was january goal is to have it ready in may/june.

Transom holes and side vents/ stern light filled and faired got her pretty damn flat with no filler so skim coated it after this with some 3m marine filler.

The following 2 users liked this post by Nickc919:

hogie roll (04-08-2024), resurrected (04-10-2024)

#8

My wood working skills arent the greatest so we phoned a friend and got the trim king himself Nick out here to make this killer windscreen. Ton of compound angles and he knocked it out perfect.

Changes the whole look of this boat!

Cutting cabin berth floor out to add bulkheads and a ballast tank

Bulkhead templated

Decided to fill the deck hatch in love the look of a clean deck and the old hatch was a bulky ugly mess. Used some balsa to get the shape.

All glassed in time to fair it out

Screwed a peice of thin plywood up underneath and wet stuck some 1708 to get it to form to the shape. Worked really well

Alot of grinding to prep the windshield install. I decided to glass it to the deck which i know can cause cracks in future but it will be super strong. Bolted it and stuck it with some thickened resin and then started to glass it up

The following users liked this post:

resurrected (04-10-2024)

#9

Used west systems 407 fairing compound on it wanted to try something other than 3m since its a bear to sand that 3m filler. West systems takes alot longer to set up but sands and lays really nice.

Bonded down with thickened resin

Cutting the glass to size. Went with 2 layers of 1708 over it which should be plenty.

The whole boats getting sanded so i wasnt really worried about getting resin on the deck and dash but shes glassed in. Huge thanks to all my good friends for helping me out Fred Nick and Doug have come in clutch with helping on the hull.

The following 8 users liked this post by Nickc919:

87MirageIntruder (04-09-2024), ccarloss (04-01-2024), Craney (03-31-2024), hogie roll (04-08-2024), JOACH1M (04-11-2024), Padraig (03-31-2024), resurrected (04-10-2024), Stuckonstupid (04-01-2024)