Fountain 47, 2372cid single engine diesel

#302

Registered

Two weeks gone after last update and project has gone forward pretty good.

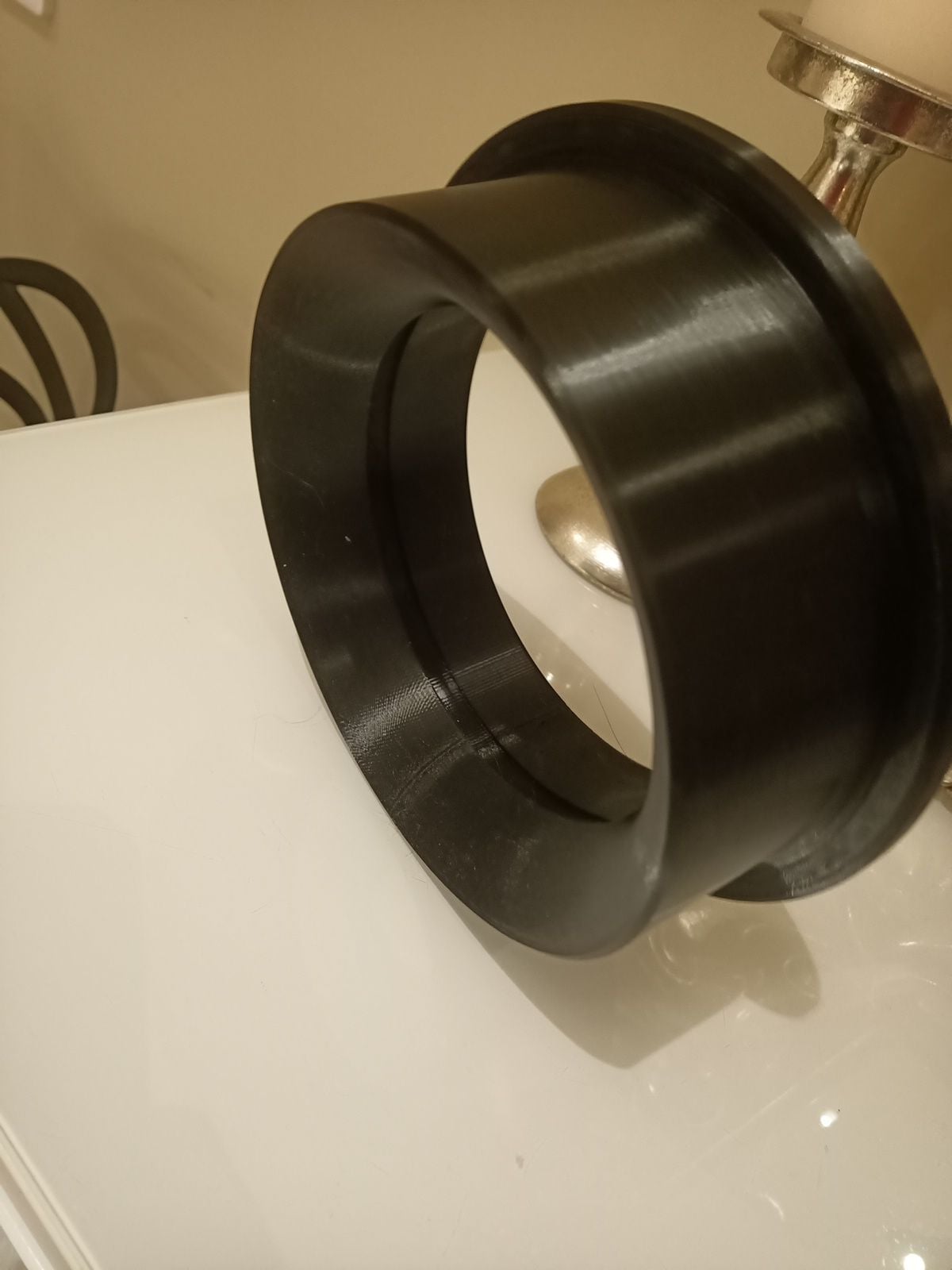

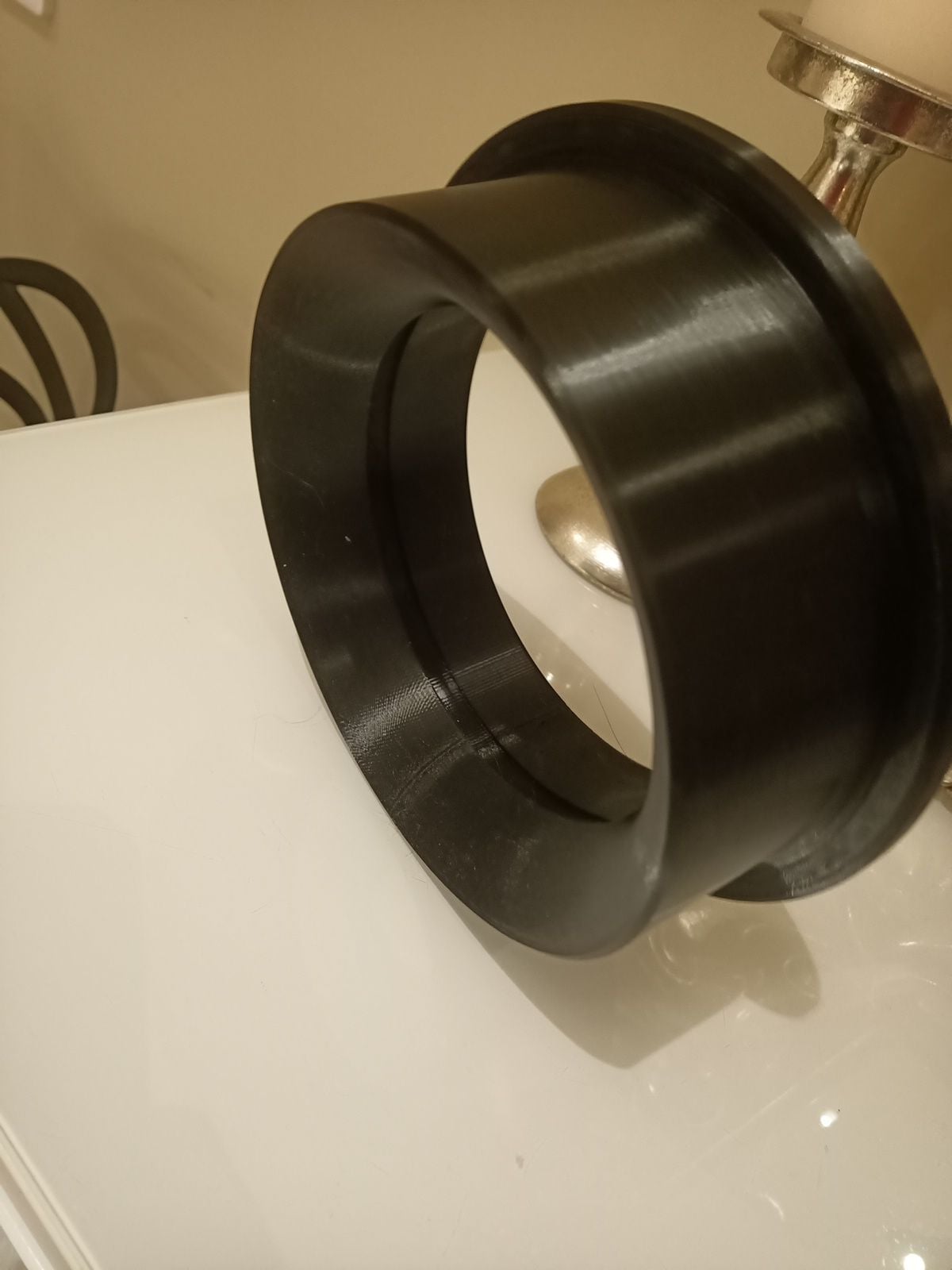

I try new to me manufacturing method, 3D printing. Turbocharger inlet adapter for Scania D16 air filter succeeded well. Front mount that keep filter in place is not ready yet.

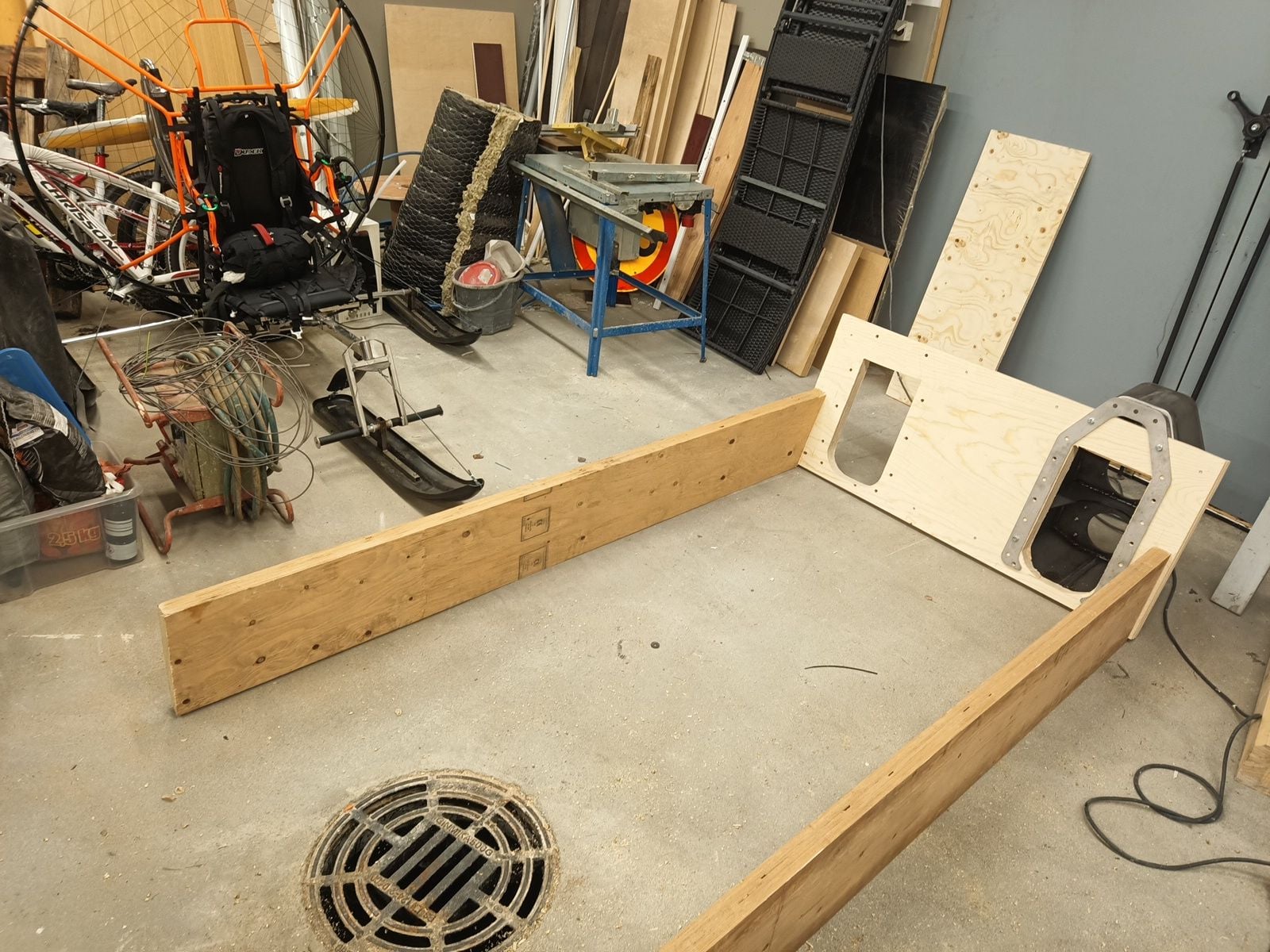

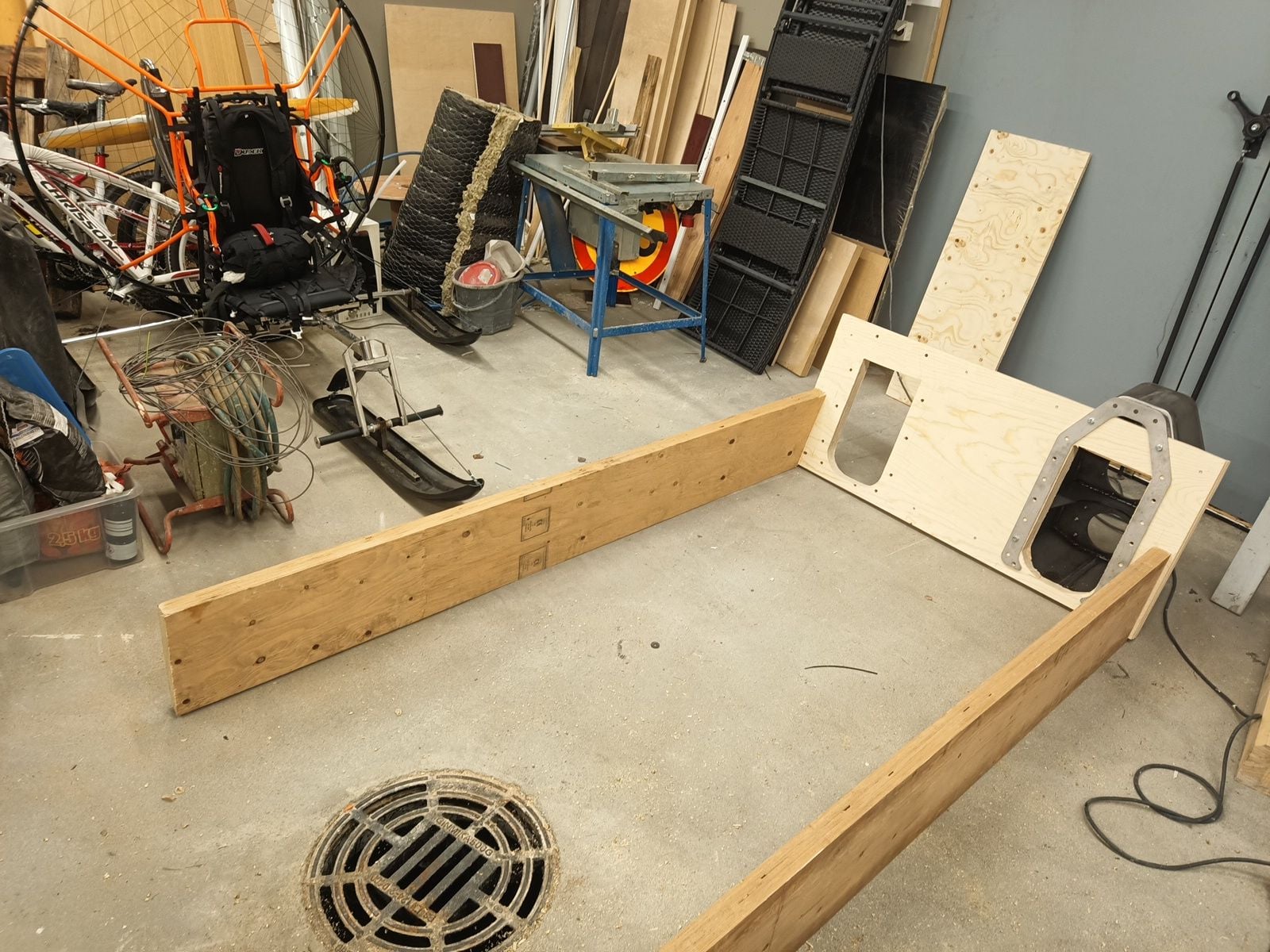

I made boat copy from wood with my little helper girl. She can already give me some tools and screws, maybe after few years I don't need do all myself anymore....

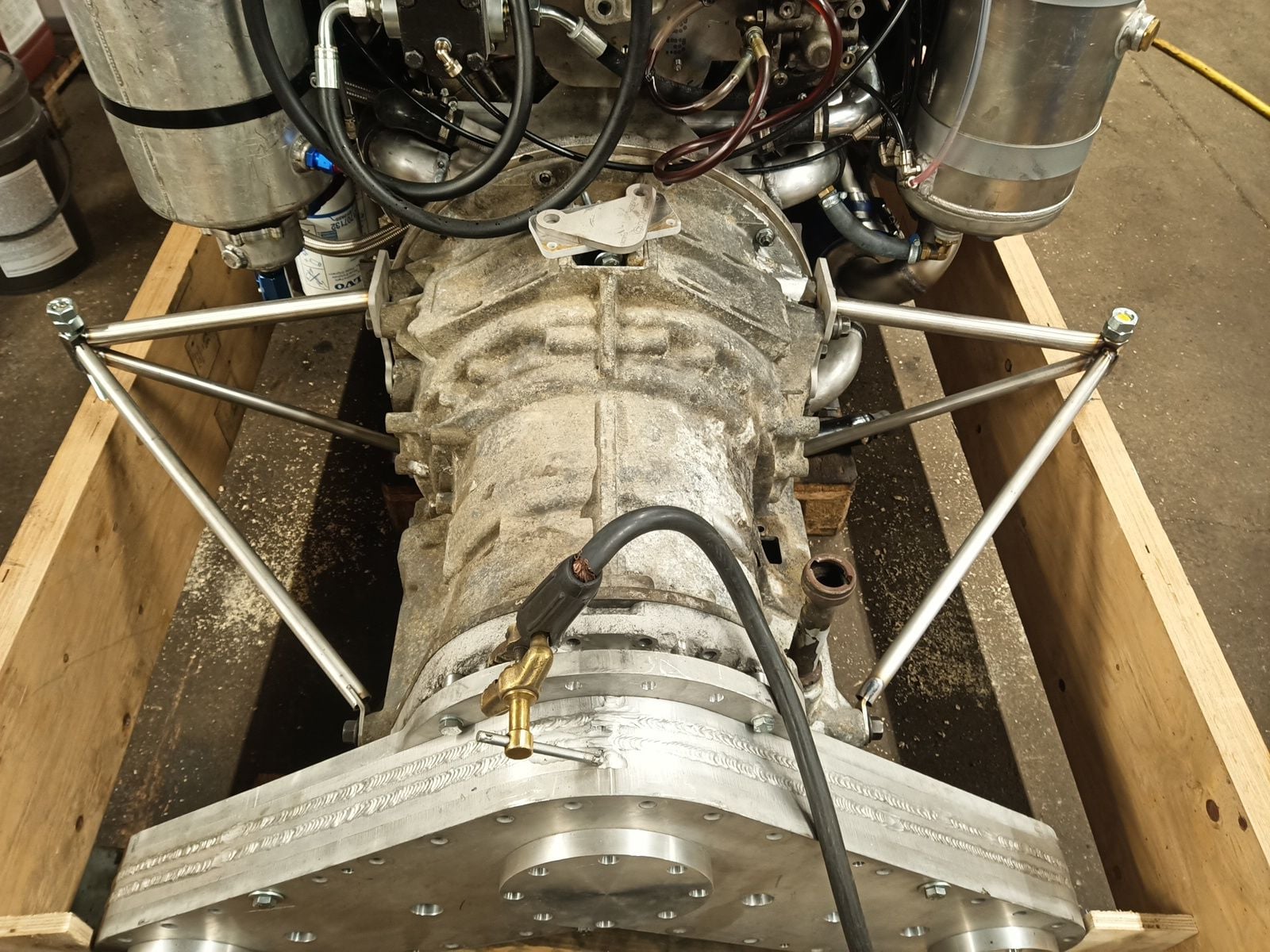

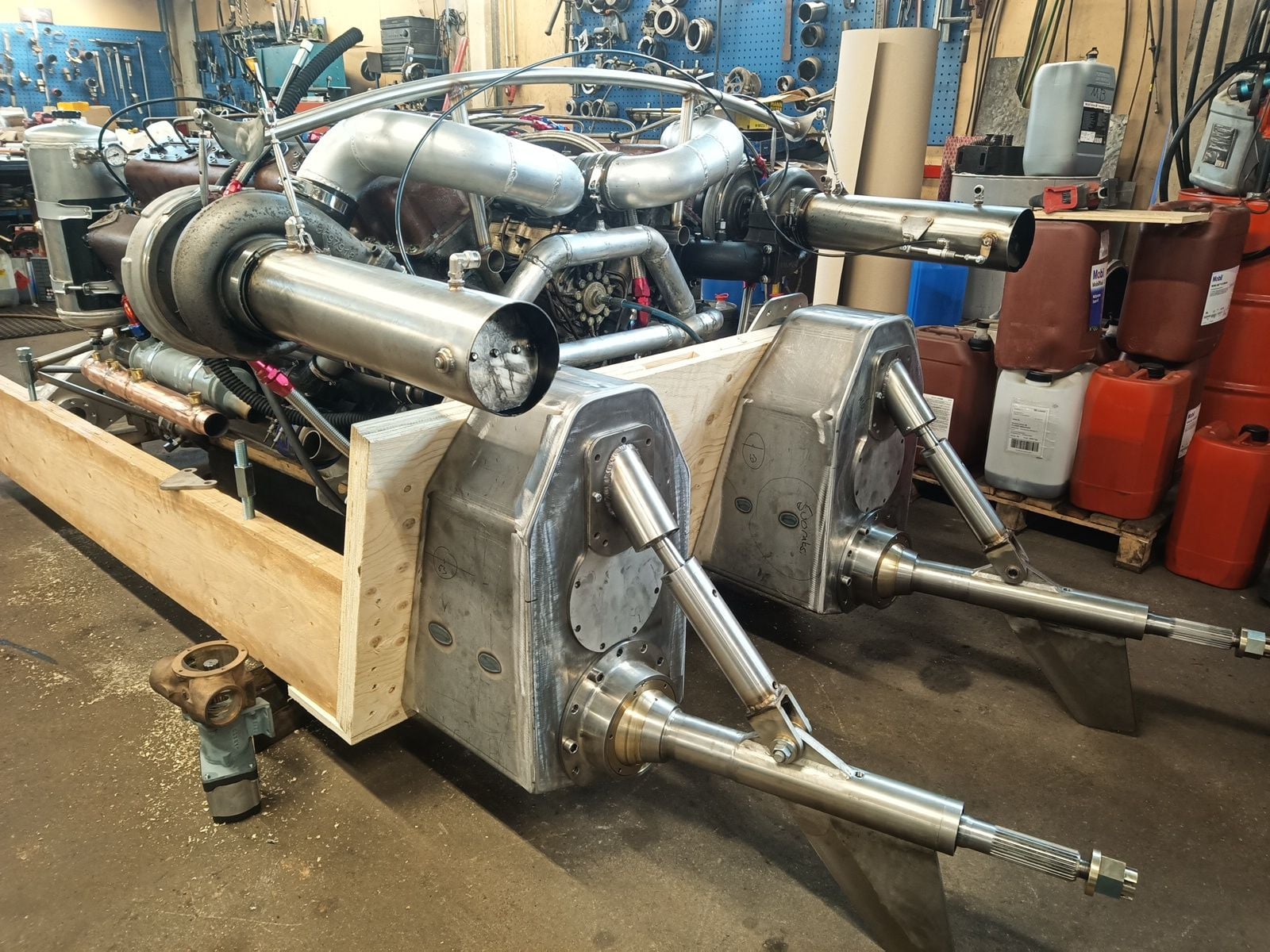

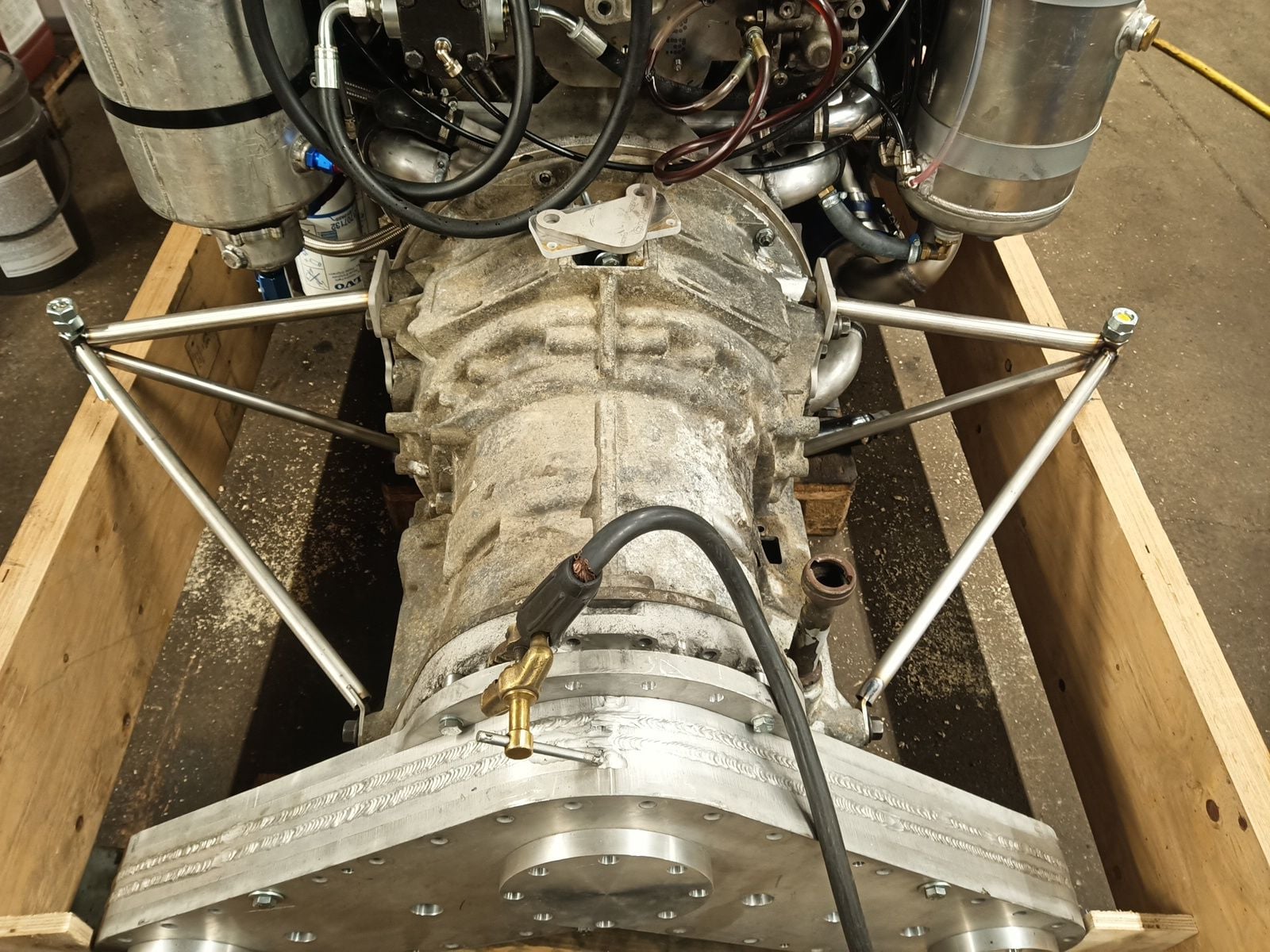

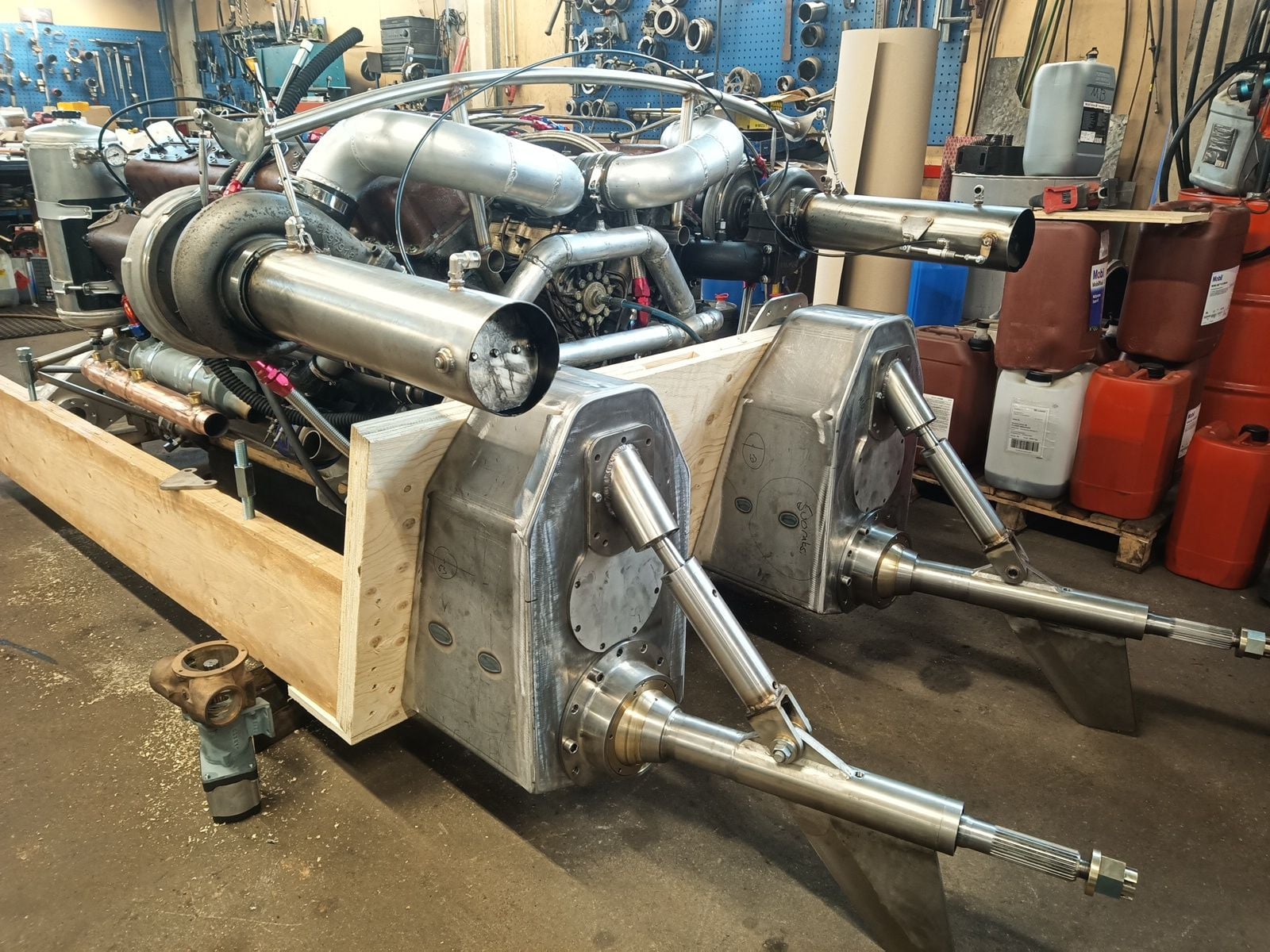

Happy to see powerline as a whole first time! Not only CAD drawings and mental images but real things start take shape.

Wooden copy was first boat project part that was done in my new garage, boat goes there too soon. I think to use it in truck quick wash then lift, drag and jack it in garage, boat have four years dirty on it.

Engine compartment get pretty full, package is so big that only 4" free space longitudinally, sideways is good space. Wooden mock up is accurate copy from transom, notch and future ones stringers. Stringers I tought I would make urethane foam core carbon reinforce glassfiber.

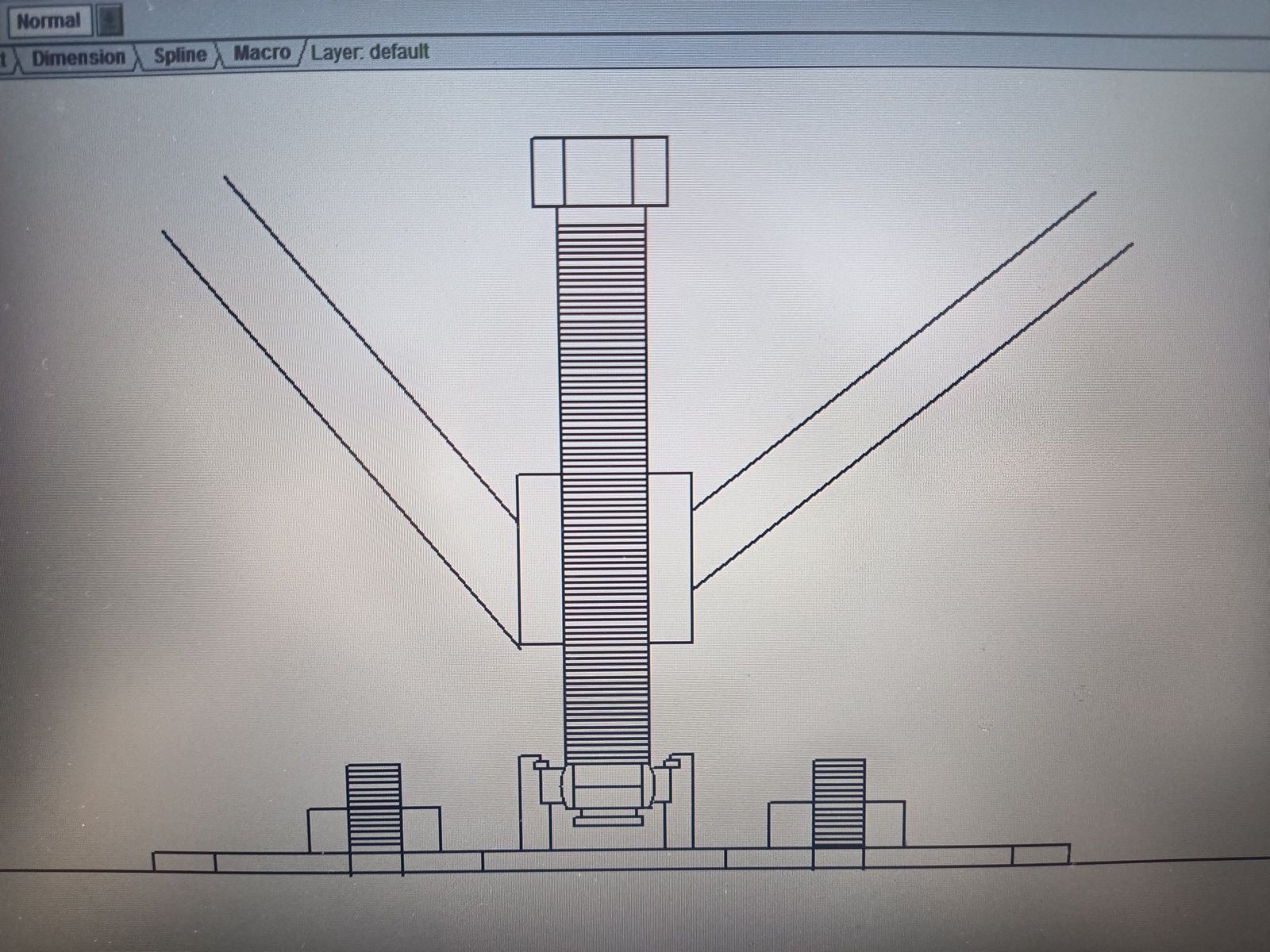

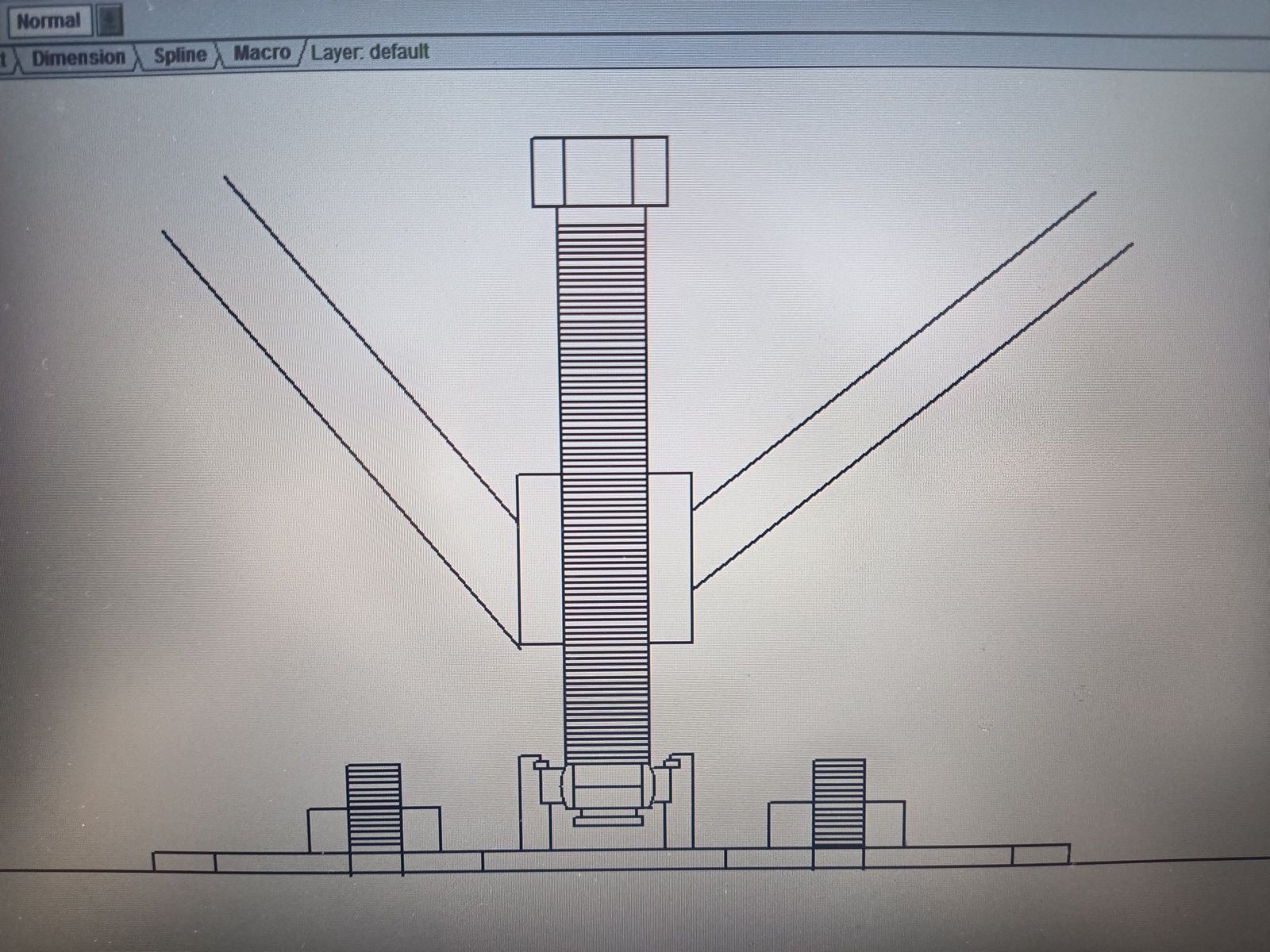

I made tubular engine mounts to save some weight, they came out very light and strong thanks to geometry. All tubes see only pull or push forces, push force tubes are bigger diameter than others to prevent buckling. I weld extra reinforcement to pull side tubes if my welds is not good enough. Engine mounts are solid, no rubber, and they have plenty of height adustment so driveshaft angles can be adjusted as shallow as possible. Longitudial adjustment is must also to get driveshaft lenght right. CV joints will make excessive heat if they are not centered at full power.

Steering cylinders fixed points have to find out next and engineer water pickup for raw water. I hope to get it wet next summer or autumn, let see will it succeed.

I try new to me manufacturing method, 3D printing. Turbocharger inlet adapter for Scania D16 air filter succeeded well. Front mount that keep filter in place is not ready yet.

I made boat copy from wood with my little helper girl. She can already give me some tools and screws, maybe after few years I don't need do all myself anymore....

Happy to see powerline as a whole first time! Not only CAD drawings and mental images but real things start take shape.

Wooden copy was first boat project part that was done in my new garage, boat goes there too soon. I think to use it in truck quick wash then lift, drag and jack it in garage, boat have four years dirty on it.

Engine compartment get pretty full, package is so big that only 4" free space longitudinally, sideways is good space. Wooden mock up is accurate copy from transom, notch and future ones stringers. Stringers I tought I would make urethane foam core carbon reinforce glassfiber.

I made tubular engine mounts to save some weight, they came out very light and strong thanks to geometry. All tubes see only pull or push forces, push force tubes are bigger diameter than others to prevent buckling. I weld extra reinforcement to pull side tubes if my welds is not good enough. Engine mounts are solid, no rubber, and they have plenty of height adustment so driveshaft angles can be adjusted as shallow as possible. Longitudial adjustment is must also to get driveshaft lenght right. CV joints will make excessive heat if they are not centered at full power.

Steering cylinders fixed points have to find out next and engineer water pickup for raw water. I hope to get it wet next summer or autumn, let see will it succeed.

Some seriously good machining work here. I've been following for quite some time, as a toolmaker/modelmaker, admiring the work you're doing on what appears to be fairly antiquated equipment. I keep waiting to catch a glimpse of the more modern machinery that you're REALLY doing this work on.

Hats off.

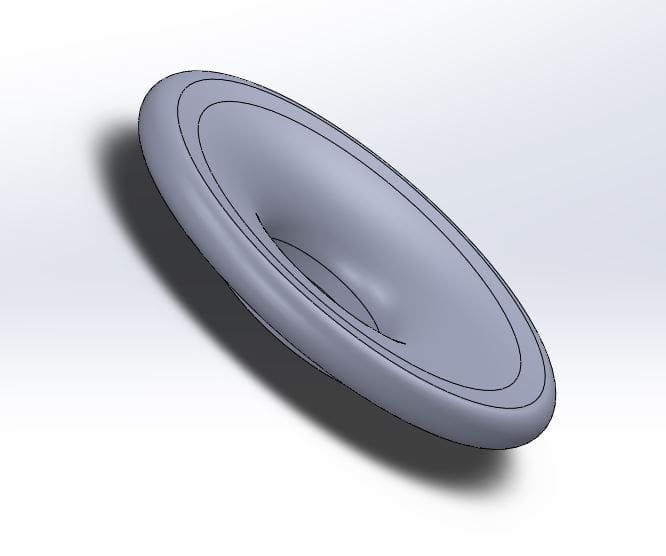

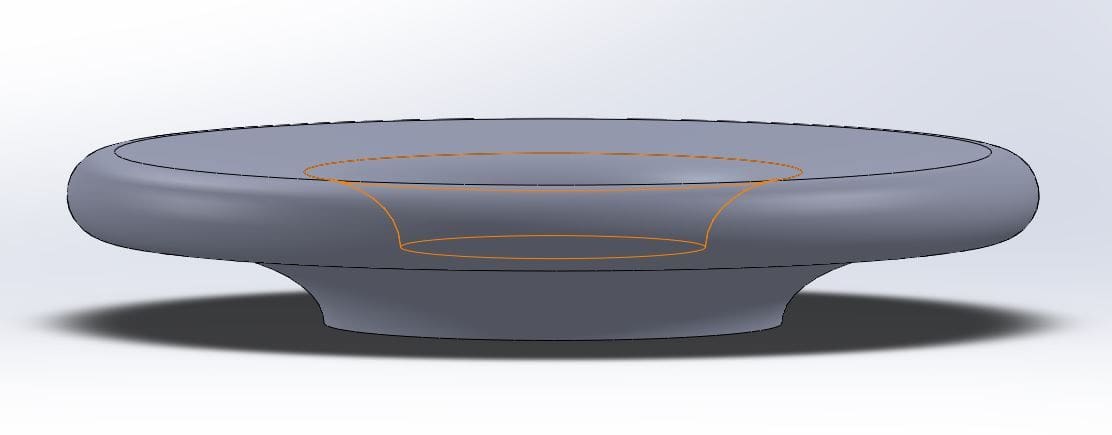

Hats off.Something to chew on, though.... A small group of model boating guys did some significant work on bellmouth geometry for our carburetors. They turned up probably a thousand or more (really) bellmouths for carburetors for engines ranging from 2.5 to 15cc single cylinder two strokes, with carb bores ranging from 6mm to probably close to 20mm (maybe larger). There was an aerospace engineer among them, so they had a pretty good starting point, but were eventually able to significantly improve the flow of these carbs at WOT, over that of the OEM carb intakes. These countless iterations started with hand profiled curves, then graduated to a guy who had open access to a CNC lathe that could spit out several dozen of various deviations in an afternoon. Sadly, I was not that guy, as I still worked for a shop, instead of for myself, and I did not have that kind of unfettered access (they asked; I had to decline). What they eventually settled on was something very much like this:

These are screenshots of a quick, rough guestimate, but the concept is well represented. The ID is Ø4" and the perimeter OD is Ø12-3/4". I have no idea what your turbos' intake diameter is, or how much space you have to work with, so I just tossed this together, by eyeball guestimation, for the screenshots. I also don't know if you're shoehorned into using that filter, as it obviously it wouldn't work with anything close to this design, but, if you can find one that will work, something more akin to the old-school automotive intake air filter, with larger diameter than height, a profile like this will yield much more airflow than what you have there. Being more of a series of pulses on a 2-stroke than "flow", these bellmouths were instrumental in literally DOUBLING the HP of the smaller engines, and at least a 50% increase in the largest of them. Being turbos, it may not matter nearly as much, if any, but looking at pics on ProCharger's website would indicate THEY think it helps. The one thing I can see with their bellmouths that deviated from what we found with our 2-strokes is that they have a relatively sharp outer perimeter where ours are fully rounded (it mattered), as the screenshots show. They found a ratio between the bore diameter and the perimeter OD, as well as the height from the "straight through" terminus and the top of the bellmouth, and the elliptical transition between, and the narrow flat between the elliptical profile and the radius around the outer perimeter, where there was a definite peak in airflow. While I was not in on the machining or the dyno sessions, I CAN tell you that these bellmouths made a world of difference. All other factors the same, simply changing carburetors from stock to one with the bellmouth, we could significantly increase prop diameter and pitch (ours are much cheaper, and we typically had dozens to choose from), sometimes yielding as much as a 15% increase in SAW speeds (radar), and a noticeable decrease in RPM loss (audible tach) in the turns.

Take this for what it is. You seem to have the time on your hands, and the willingness to go to the effort, so it was worth tossing this out there.

Otherwise, carry on. Like Wildman says... I can't wait to see this thing run.

Thanks. Brad.

Last edited by Brad Christy; 02-21-2024 at 09:51 AM.

The following 2 users liked this post by Brad Christy:

kidturbo (04-05-2024), thegoodson (02-21-2024)

#303

Registered

Thread Starter

IGetWet, engine, transmission and splitbox weight about 1300kg (2866lbs) complete with all fluids so mounts will see 325kg(700lbs) static weight each. I try calculate it and get 10 times safety factor. Inertia force will make much more than static weight when boat landing after jump, I think to reinfoce mounts with triangle sheet metal pieces to every corner.

3D printing is very good way to fabricate parts but I like old school milling and welding, no need for complicate 3D drawings, but some parts will benefit new age engineer methods. All sheet metal parts I buy from my friend shop that have water cut machine, no sense to use angle grinder and drill.

Bad Christy, two stroke engines and hi performance N/A four stroke engines work by pulses. velocity stacks are very critical in high speed air stream. This engine have almoust constant flow that are pretty slow so there is no real benefits for special shaped stacks. two strokes power differences may cause air fuel mixture also, differrent air speed to carburator metering port change AFR critically.

3D printing is very good way to fabricate parts but I like old school milling and welding, no need for complicate 3D drawings, but some parts will benefit new age engineer methods. All sheet metal parts I buy from my friend shop that have water cut machine, no sense to use angle grinder and drill.

Bad Christy, two stroke engines and hi performance N/A four stroke engines work by pulses. velocity stacks are very critical in high speed air stream. This engine have almoust constant flow that are pretty slow so there is no real benefits for special shaped stacks. two strokes power differences may cause air fuel mixture also, differrent air speed to carburator metering port change AFR critically.

#304

Registered

IGetWet, engine, transmission and splitbox weight about 1300kg (2866lbs) complete with all fluids so mounts will see 325kg(700lbs) static weight each. I try calculate it and get 10 times safety factor. Inertia force will make much more than static weight when boat landing after jump, I think to reinfoce mounts with triangle sheet metal pieces to every corner.

3D printing is very good way to fabricate parts but I like old school milling and welding, no need for complicate 3D drawings, but some parts will benefit new age engineer methods. All sheet metal parts I buy from my friend shop that have water cut machine, no sense to use angle grinder and drill.

Bad Christy, two stroke engines and hi performance N/A four stroke engines work by pulses. velocity stacks are very critical in high speed air stream. This engine have almoust constant flow that are pretty slow so there is no real benefits for special shaped stacks. two strokes power differences may cause air fuel mixture also, differrent air speed to carburator metering port change AFR critically.

3D printing is very good way to fabricate parts but I like old school milling and welding, no need for complicate 3D drawings, but some parts will benefit new age engineer methods. All sheet metal parts I buy from my friend shop that have water cut machine, no sense to use angle grinder and drill.

Bad Christy, two stroke engines and hi performance N/A four stroke engines work by pulses. velocity stacks are very critical in high speed air stream. This engine have almoust constant flow that are pretty slow so there is no real benefits for special shaped stacks. two strokes power differences may cause air fuel mixture also, differrent air speed to carburator metering port change AFR critically.

The flow benches that were used on the bellmouths used constant flow, and the various shapes greatly affected vacuum required to achieve a given flow. Curiously, one of the most influential greatest features was the rounded outer perimeter. There had been several guys in the past, both in the model world and in just about every other sector of the racing community, that had been making and using "velocity stacks" that greatly resembled trumpet bells, with sharp outer rims. Using these as a starting base, a high-speed camera, filming our two strokes running on the dyno, was able to capture images that demonstrated, in hindsight, why the rounded outer perimeter was so beneficial. In our two. The reversion that occurs every time the rotary valve slammed shut expelled fuel droplets that didn't make it back into the airflow, and the longer velocity stacks didn't correct this, as the droplets were escaping the airflow radially, not longitudinally. The rounded outer perimeter solved this issue. This is what led them to go larger with the diameter, shorter with the length and add the rounded outer perimeter. Obviously, this reversion isn't happening at the intake of a throttle body feeding multiple cylinders, and especially the intake of a turbocharger, but the bellmouth approach, instead of the velocity stack approach, did lead to much more efficient air draw, that then translated into vastly improved performance on the water. The significant difference is that you're probably not actually reaching for that last bit of performance, and those guys were. They were trying to shave tenths of seconds of a one mile, six lap oval time trial, at a performance level where a tenth of a second gain was considered a major improvement.

I have no doubt that what you've printed up will greatly improve airflow efficiency over that of the intake profile of the turbocharger alone. Videos I've seen of filter MFRs demonstrating something VERY similar shows significant improvement over a simple straight stack, even with the filter in place. I also have no idea how much airflow you actually need, but I was basing my suggestion on the assumption that, even at what we'd consider very low RPM, you'd need a farq ton of air for that beast (basic math shows over five times that of a 454 V8 at the same RPM).

I love what I've seen so far. It's awesome to see someone going so far outside the box.

Thanks. Brad.

#305

Registered

Thread Starter

Actually I remember Steve Morris made bellmouth testin in engine dyno. It helped airflow moderately, but it was centrifugal supercharger so rpm depends engine rpm, turbocharger may act little different. Flow will increase but will not make world changing differences.

#306

Registered

Thread Starter

Boat is in home garage now!!!

We did big job with my friends to get it home. First after four years storage outside air canopy, tires was leaked empty, one had hole in inner tube. Jacking and more work but done, after that my Massey Ferguson 3095 fron tyre get broke. After all work I pulled boat out of canopy and bring it to neighbour truck company wash line. They made good job and four years sh#t is off, boat is quite good shape.

Weather forecast said no rain or snow in ten days, off course every day come sleet and snow. I had to build front loader fit pulling eye to tractor, boat is so long that no other way to get it moved in tight places

We did big job with my friends to get it home. First after four years storage outside air canopy, tires was leaked empty, one had hole in inner tube. Jacking and more work but done, after that my Massey Ferguson 3095 fron tyre get broke. After all work I pulled boat out of canopy and bring it to neighbour truck company wash line. They made good job and four years sh#t is off, boat is quite good shape.

Weather forecast said no rain or snow in ten days, off course every day come sleet and snow. I had to build front loader fit pulling eye to tractor, boat is so long that no other way to get it moved in tight places

The following 2 users liked this post by ksalmine:

RSCHAP1 (03-04-2024), Twin O/B Sonic (03-03-2024)

#307

Registered

Thread Starter

I pulled it to home, 9km distance that goes fine but my yard road was too narrow and have too tight turn to get boat through. We shoveled snow away inner turn to get more space, it was not enough and boat had to turn with hoists and ropes.

Yeasterday we lifted and jacked it inside garage, that was pretty easy job with crane truck.

Garage door height was too low, I had to remove TV antenna top off radar arc and take trailer wheels off. Trailer rolled nice just on wheel hubs, little force needed to pull rest distance that crane can't lift it in garage.

The following 9 users liked this post by ksalmine:

87MirageIntruder (04-17-2024), AllDodge (03-03-2024), endeavor1 (03-06-2024), rak rua (03-03-2024), RedBoatFl (03-09-2024), RSCHAP1 (03-04-2024), scippy (03-08-2024), thegoodson (03-03-2024), Twin O/B Sonic (03-03-2024)

#309

Gold Member

All the mechanical and engineering work you’ve been doing, I’d forgotten about the work you’ll need to do on the boat! Pretty neat fit in the garage, just getting it in there was a project.

Keep up the good work, there’s lots to look forward to.

RR

Keep up the good work, there’s lots to look forward to.

RR

The following 2 users liked this post by rak rua:

ksalmine (03-08-2024), Twin O/B Sonic (03-08-2024)

#310

Registered

Ksalmine,

And I thought having to take the spindle motor, Z-axis servo and power drawbar off the top of my mill to get it into, and then out of, my garage was a lot of work. Jeez.....

You're definitely one of those "whatever it takes" kinda guys. Gotta love it

Thanks. Brad.

And I thought having to take the spindle motor, Z-axis servo and power drawbar off the top of my mill to get it into, and then out of, my garage was a lot of work. Jeez.....

You're definitely one of those "whatever it takes" kinda guys. Gotta love it

Thanks. Brad.