Bravo 3 Failing? Oil Analysis Results

#31

Charter Member # 55

[QUOTE=scarabman;4644265]

I guess you could call that slipping. They get glazed and won't engage the gears which causes a delay when shifting gears. I was more referring to they are either engaged or they are not.

It won't create enough heat to burn the lube and he hasn't mentioned any issues with delays shifting into gear.

Cone clutches either work or they don't. They don't slip.

That is a 100% incorrect statement. Cone clutches very often start to slip going into gear prior to failure. In fact, slipping is usually the give away that they have reached the end of their life expectancy. Some operators may notice it, some do not

That is a 100% incorrect statement. Cone clutches very often start to slip going into gear prior to failure. In fact, slipping is usually the give away that they have reached the end of their life expectancy. Some operators may notice it, some do not

It won't create enough heat to burn the lube and he hasn't mentioned any issues with delays shifting into gear.

#32

Registered

Thread Starter

Join Date: Dec 2005

Location: Illinois

Posts: 98

Likes: 0

Received 0 Likes

on

0 Posts

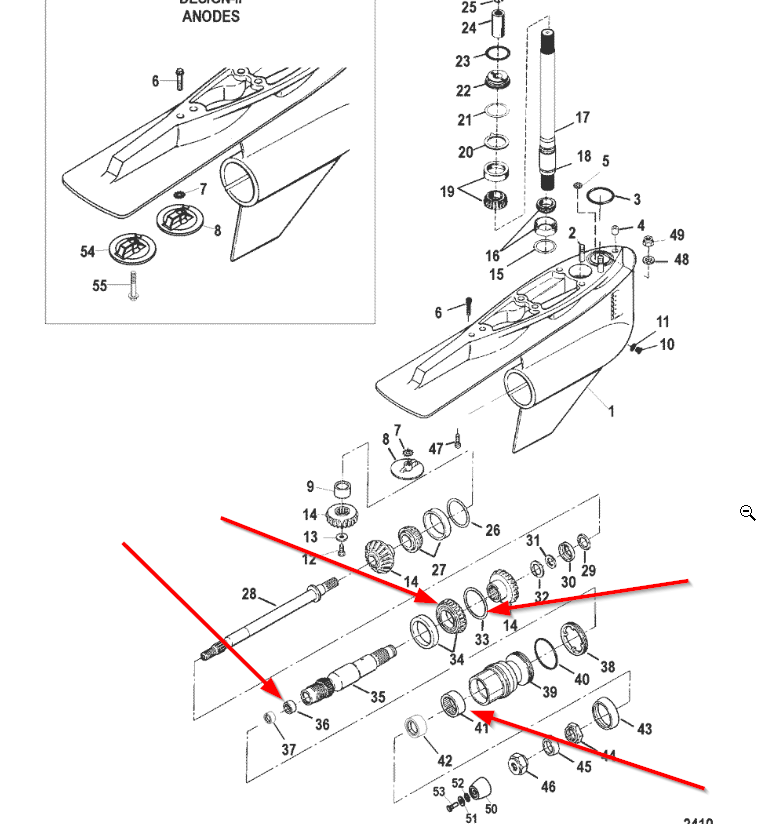

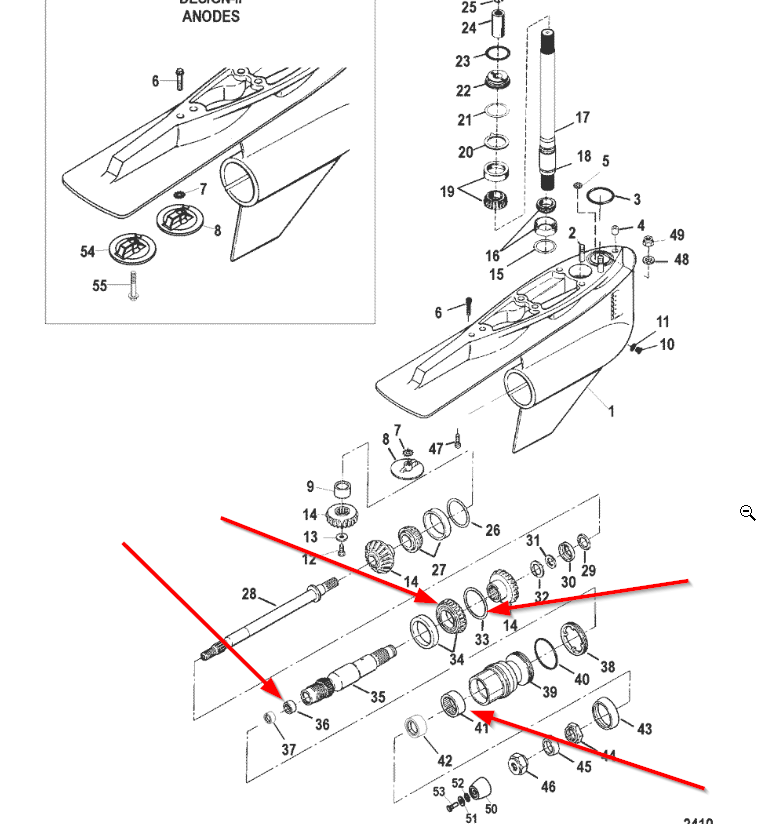

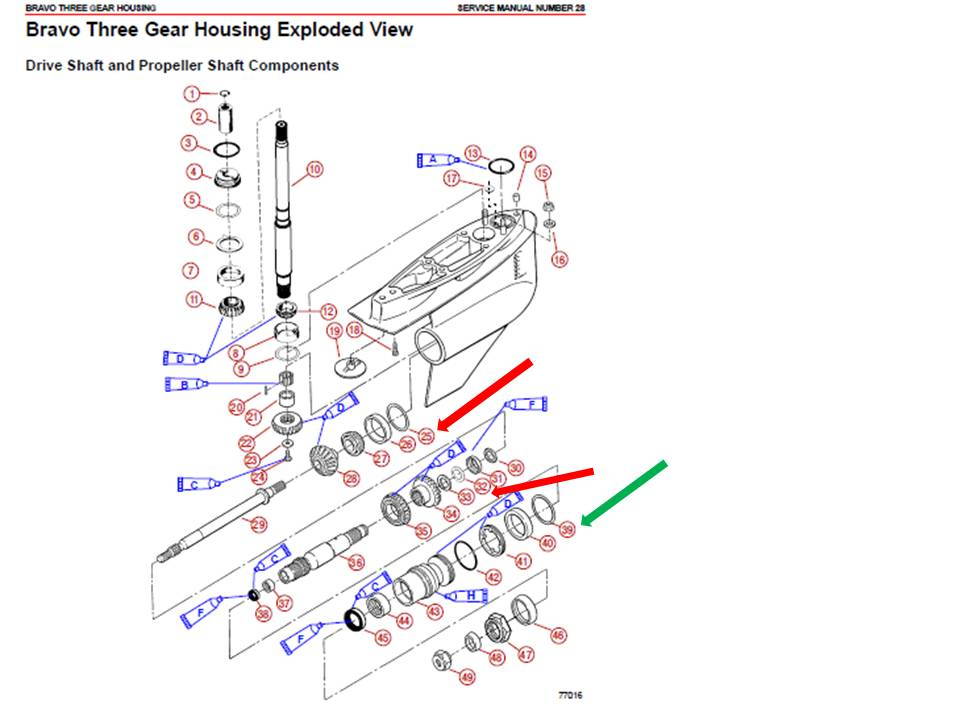

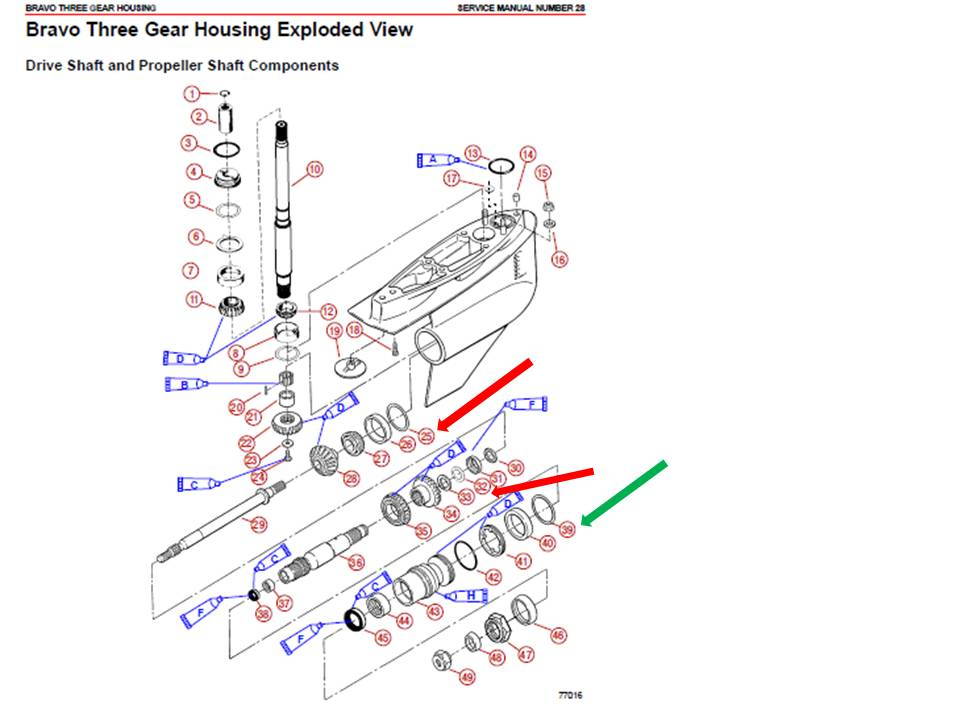

I received my merc service manual from fleabay. There is a spec for prop shaft axial movement but not radial movement. It appears that radial movement is determined by the prop shaft bearings (41&36) and there is no adjustment. I plan to replace these bearings, It looks like I will need two special tools and should be fairly straightforward.

Axial play I am having some trouble with and the manual provides the spec but does not go into detail on how it is adjusted. From what I can tell it’s one of three ways:

1. Bearing and shim stackup for the bearing on the end of the propeller shaft (33 &34).

2. How tight you tighten the bearing retaing nut.

3. It is preset when setting the drive shaft (17) pinion depth? The seems cumbersome as you wouldn't know until complete assembly.

Anyone know for sure.

Please feel free to shoot holes in my logic.

Axial play I am having some trouble with and the manual provides the spec but does not go into detail on how it is adjusted. From what I can tell it’s one of three ways:

1. Bearing and shim stackup for the bearing on the end of the propeller shaft (33 &34).

2. How tight you tighten the bearing retaing nut.

3. It is preset when setting the drive shaft (17) pinion depth? The seems cumbersome as you wouldn't know until complete assembly.

Anyone know for sure.

Please feel free to shoot holes in my logic.

#33

Registered

Thread Starter

Join Date: Dec 2005

Location: Illinois

Posts: 98

Likes: 0

Received 0 Likes

on

0 Posts

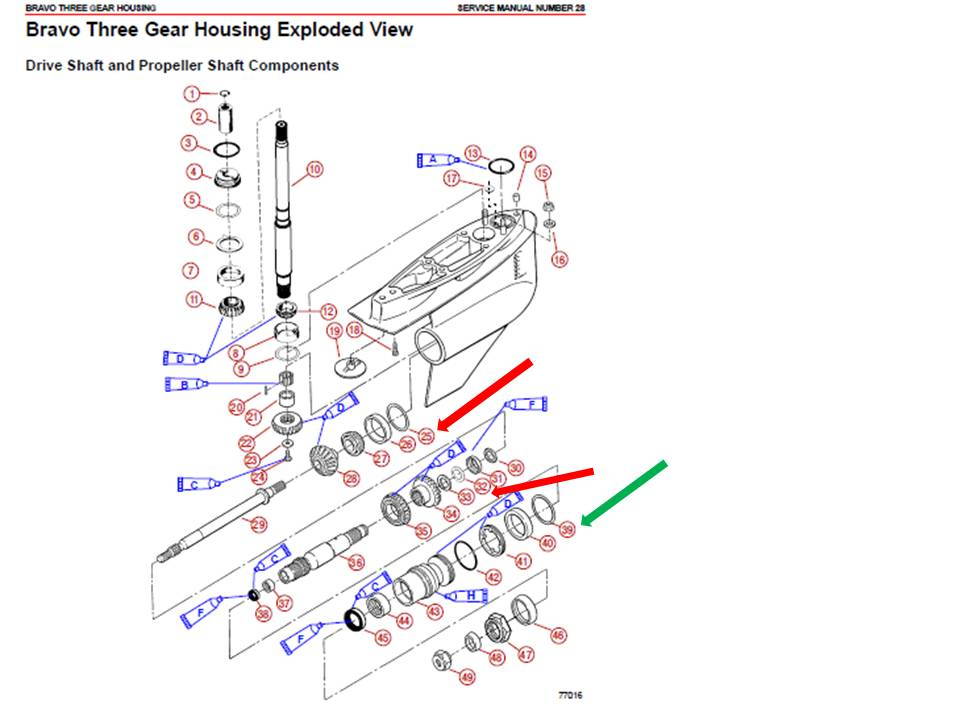

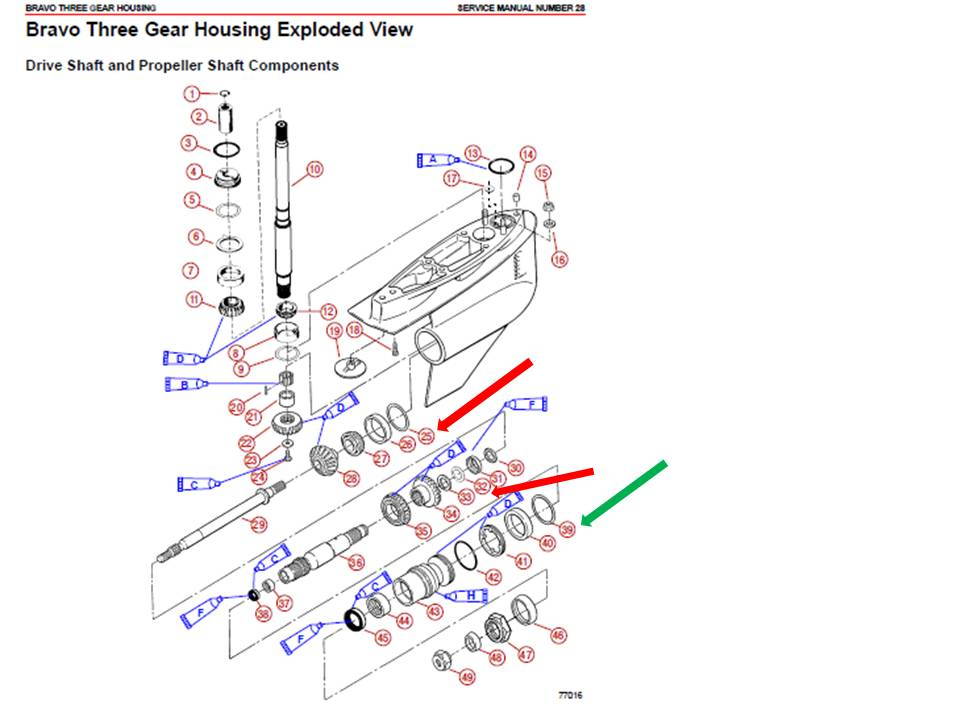

The report back so far is.... One of the teeth on the upper pinion is damaged, Other gears are showing signs off pitting, upper bearing cages are pitted.

Last edited by mtocrs1; 08-21-2018 at 10:38 PM.

#34

Registered

iTrader: (1)

The play in the drive is all controlled by the bearings and shims, 25, 39 and 32. Shims 25 and 32 normally are reused and are only changed if play does not meet spec, or if they where damaged during disassembly. The bearing retaining nut and carrier is torqued to spec before play is checked. I had to buy several of the tools to rebuild my lower B3 years ago.

https://forums.iboats.com/forum/engi...utdrive-repair

https://forums.iboats.com/forum/engi...utdrive-repair

Last edited by AllDodge; 08-21-2018 at 04:18 PM.

#35

Registered

[QUOTE=scarabman;4644265]

someone explain to me how a “slipping” clutch can turn into a failed drive. Sure the shifting mechanism is worn out. How does that translate to broken gears etc? I don’t understand...I ask because ours started to slip in reverse. Going to rebuild them this winter but want to run a few more weeks. Side note our gear oil always comes out green and looking unused.

Cone clutches either work or they don't. They don't slip.

That is a 100% incorrect statement. Cone clutches very often start to slip going into gear prior to failure. In fact, slipping is usually the give away that they have reached the end of their life expectancy. Some operators may notice it, some do not

That is a 100% incorrect statement. Cone clutches very often start to slip going into gear prior to failure. In fact, slipping is usually the give away that they have reached the end of their life expectancy. Some operators may notice it, some do not

#36

Registered

Thread Starter

Join Date: Dec 2005

Location: Illinois

Posts: 98

Likes: 0

Received 0 Likes

on

0 Posts

These are some pics of what was found, the upper is getting rebuilt with new bearings and gears as we speak, the lower..... well it will be flushed as best as possible and I will cross my fingers for a while and continue to monitor the gear oil. There was a bearing roller that was missing, it was found in the shifter linkage. I will get more specifics on what bearing it came from.

I guess I learned the oil doesnt lie....

Last edited by mtocrs1; 08-21-2018 at 10:44 PM.

#37

Registered

Thread Starter

Join Date: Dec 2005

Location: Illinois

Posts: 98

Likes: 0

Received 0 Likes

on

0 Posts

The play in the drive is all controlled by the bearings and shims, 25, 39 and 32. Shims 25 and 32 normally are reused and are only changed if play does not meet spec, or if they where damaged during disassembly. The bearing retaining nut and carrier is torqued to spec before play is checked. I had to buy several of the tools to rebuild my lower B3 years ago.

https://forums.iboats.com/forum/engi...utdrive-repair

https://forums.iboats.com/forum/engi...utdrive-repair

#38

Registered

Yup, she wasn't long for this world. Hey, you got a lot of hours out of that drive considering it is pushing a heavy, single engine boat. Hopefully nothing in the lower is shedding metal and contaminates the newly rebuilt upper. However, I bet your lower gears are pitted as well.

#39

Registered

#40

Registered

Thread Starter

Join Date: Dec 2005

Location: Illinois

Posts: 98

Likes: 0

Received 0 Likes

on

0 Posts

Yup, she wasn't long for this world. Hey, you got a lot of hours out of that drive considering it is pushing a heavy, single engine boat. Hopefully nothing in the lower is shedding metal and contaminates the newly rebuilt upper. However, I bet your lower gears are pitted as well.