please evaluate these pics for me

#1

Registered

Thread Starter

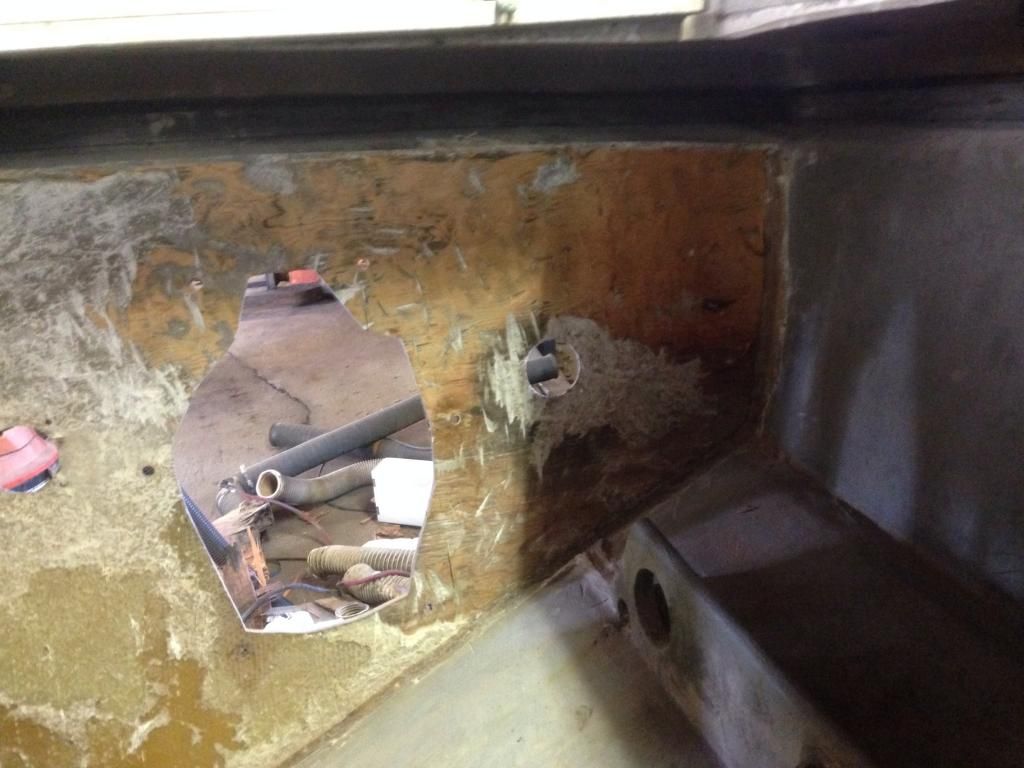

I am rebuilding my 1972 Magnum 27 Sedan and pulled the drives, engines, and transom plates, this is what the transom looks like, it is dry but there is a little delamination of some of the plywood at the lower side of the cutout. I am swapping from the old 250/270 Volvo drive to the 290/SP so the transom cutout will need to be enlarged anyway, am I ok or should I be replacing the transom. If I replace the transom I'll probably raise the X 2" at the same time, but if the transom does not need replacing it will obviously be much less work.

considering the shape of the outdrives, I was thinking it would be much worse...

considering the shape of the outdrives, I was thinking it would be much worse...

#3

Registered

iTrader: (2)

Join Date: Aug 2005

Location: Between A Womans Leggs in IL

Posts: 6,306

Likes: 0

Received 1 Like

on

1 Post

poke at it with a pic..if it goes in like styrofoam then its bad..the 290 will slow the boat down,,they are deeper in the water then the 280 t shields..you may want to reconsider..

#4

Registered

Thread Starter

I just went and compared the transom plates, it looks like if I were to align the bottom of the 290 plate I can raise the drive 2" when I make the opening bigger. The 290 plate is a full 3" taller and the drive is 1" lower from the top compared to the 270/280 transom.

I poked with a pick and its like the petrified forest... it is hard, there are a couple spots where the plywood itself is delaminating, I think its only right at the edge and will be cut out when I trim for the new plates, otherwise I will inject some epoxy into it and clamp it tight.

I poked with a pick and its like the petrified forest... it is hard, there are a couple spots where the plywood itself is delaminating, I think its only right at the edge and will be cut out when I trim for the new plates, otherwise I will inject some epoxy into it and clamp it tight.

#5

Registered

I just went and compared the transom plates, it looks like if I were to align the bottom of the 290 plate I can raise the drive 2" when I make the opening bigger. The 290 plate is a full 3" taller and the drive is 1" lower from the top compared to the 270/280 transom.

I poked with a pick and its like the petrified forest... it is hard, there are a couple spots where the plywood itself is delaminating, I think its only right at the edge and will be cut out when I trim for the new plates, otherwise I will inject some epoxy into it and clamp it tight.

I poked with a pick and its like the petrified forest... it is hard, there are a couple spots where the plywood itself is delaminating, I think its only right at the edge and will be cut out when I trim for the new plates, otherwise I will inject some epoxy into it and clamp it tight.

It doesnt look that bad. At least its not mush.

FYI there was an accident with a 27 sedan a few years ago where the boat stuffed into a wave and the deck ripped off killing the driver. If you are in there doing glasswork the deck is a good idea to get glassed on as it is only screwed on on the older boats.

#6

that delamination tells me theres been some freeze/thaw cycles with moisture present and in my experiance you are seeing maybe one fifth of the actual compromised areas. In all honesty if your doing a full resto nows the time.

man that is one uuuuuuuuugly transom assembly

man that is one uuuuuuuuugly transom assembly

__________________

Throttles- Cleveland Construction 377 Talon

08 OPA Class 1 National Champion

08 Class 1 Geico Triple Crown Champion

08 OPA High Points Champion

10 OPA Class 1 National Champion ( happy now Ed! )

Throttles- Cleveland Construction 377 Talon

08 OPA Class 1 National Champion

08 Class 1 Geico Triple Crown Champion

08 OPA High Points Champion

10 OPA Class 1 National Champion ( happy now Ed! )

#8

Registered

iTrader: (1)

Needs a transom! Dave's right. The swelling is there and you won't see all the problems elsewhere. Just the outdrive area would make me tell the customer that they need transom. If anyone of us can help just post. It's not that bad to do. Just be patient and it will all come together fine.

#9

.

piece of mind especially after you get some good quality materials back in there

__________________

Throttles- Cleveland Construction 377 Talon

08 OPA Class 1 National Champion

08 Class 1 Geico Triple Crown Champion

08 OPA High Points Champion

10 OPA Class 1 National Champion ( happy now Ed! )

Throttles- Cleveland Construction 377 Talon

08 OPA Class 1 National Champion

08 Class 1 Geico Triple Crown Champion

08 OPA High Points Champion

10 OPA Class 1 National Champion ( happy now Ed! )

#10

Registered

Thread Starter

I know Okoume is overkill, but I'm picking up two 3/4" sheets tomorrow. Found it locally for 135$ a sheet. I'm all ears when it comes to doing this. It is the first time I've ever done real fiberglass work. My plan is ATC durabond and 1708 / VE. I've read a bunch of posts here and will follow what I've seen for lay up etc. I know on the Magnum Starfires they added an extra stringer under each engine, and on some others I've seen a herringbone pattern. Which would be better to add? Also on my stringers my plan is to splice in the section I cut out. Lay it up with 1708 6" past the seam sand the sides smooth and bond another piece of 1/2" pylon each side of the stringer from the transom to the first bulkhead and glass over all of it. The current stringers are 1/2" ply. I would make them triple that. Is this a good idea or am I way off base? Can I use the same ATC durabond to piece in the sections I cut out, or is there something better?