Some Saturday Motor Fun

#1

Registered

Thread Starter

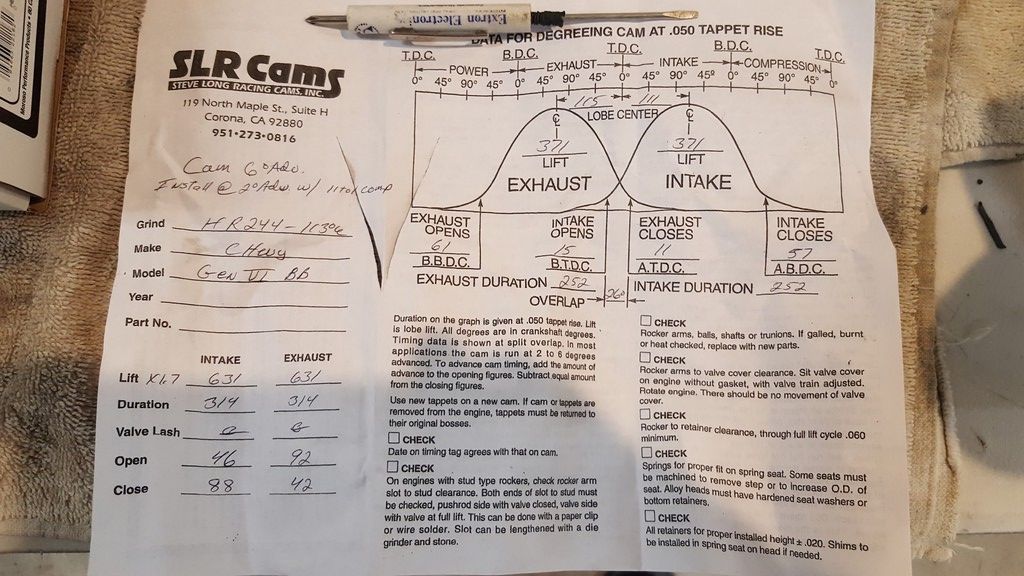

Got most of the build done today just have the valvetrain to do. This is my first boat motor build and it was a little frustrating at times as it has 088 heads on a Mark IV block with factory roller cam plate (that I have never dealt with) so I needed a Mark VI timing chain because of the stepped cam. All a great learning experience and really confused the guys at Summit. Motor is a 548 with 10:1 compression. I picked the color as I always have black motors in my drag cars so this was fun and matches the boat.

#5

Registered

Thread Starter

Finally got around to getting the valve train installed. I ended up going with the .750 wheel morels and am very happy with the comp rockers arms I chose. Haven't ever installed a hydraulic cam only solid rollers so adjusting the valves took a little getting used to. I used my 1/2 in drill to prime it for about an hour while I went through and adjusted the valves twice hoping the lifters got pumped up all the way. Going to the dyno hopefully next week and will post some numbers.

#7

Registered

iTrader: (7)

Before I got to your post I was looking at and concerned about the same. I always try and achieve inner third of the stem. The retainers look small. Yes. Not sure what's going on there but... I was going to compliment OP on his cleanliness. Also OP I like to silicon those same gaskets to the valve cover. Even though their ridgid they still have a way of slipping out in certain places. Nice to always have them attached to valve cover also while always going back in same place. What size are your pushrods?

Last edited by getrdunn; 01-29-2017 at 06:54 PM.

#8

Registered

Thread Starter

I also commented on the retainers to my machinist and he said they would be fine. The pushrods are about the only parts I reused. I do have have the adjustable pushrods to measure for correct length. I will break them out and measure one intake and exhaust.

#9

Registered

iTrader: (7)

Measurements would be good. Just curious if they jog my memory on similar builds. Also the locator under the springs might be worth checking also. Not to panic but seen springs have over .080 side play on locator and shop say was fine. Not... your retainers might be deceiving however just looks like only have your spring is covered but have seen before. Might be worth popping a spring off and just checking to make sure your retainers and locators are correct for the spring. Don't want any size to side play. Also check all you installed heights. Only take you 15 minutes. If you don't have the right tools just cut a piece of wire even and go around and ck of of them to make sure. If you don't have a spring removed tool they are very worthy of having. I have a comp that works great and also a matco but like the comp better. Pretty cheap tool that really comes in handy.

#10

Registered

iTrader: (7)

What intake you u using? Not a bad idea to lay a piece of cardboard in place of your manifold gaskets are also and tighten down a little and pull intake back off and see how close you are. Most single planes you can dry fit and do a visual with flash light or bore scope. These little things are very worthy of doing. You probably already know but just wanna throw it out there anyway.