Lifter failed, wrecked cam, were they the correct parts?

#1

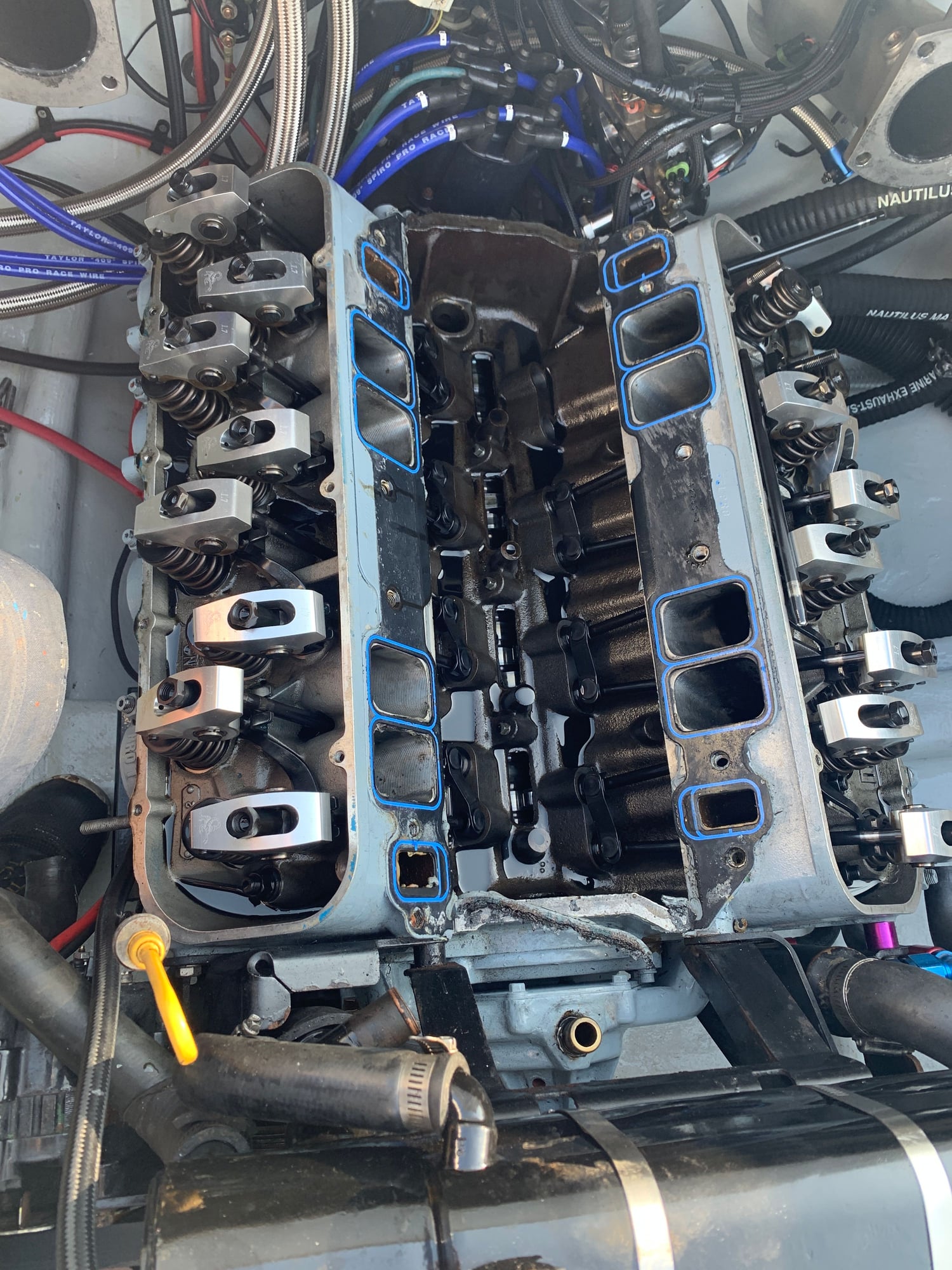

As I was running gently back up the river last week at about 1200rpm I started to notice a tapping noise from the valve train on the port bank which sounded like a lifter to me when suddenly there was a loud squealing noise which went away after a few seconds them came back and went again, by now there was a distinctly noisy lifter. I managed to get the boat back to the pontoon and stopped it as soon as I could. The oil pressure had stayed good at 40psi all the time. Suspecting a lifter issue I stripped off the intake manifold to see one lifter missing the rivet holding the link bar on and its other half of the pair rotated and jamming again the block. The roller on the broken one is now square and the cam lobe is wrecked. so It's rebuild time..

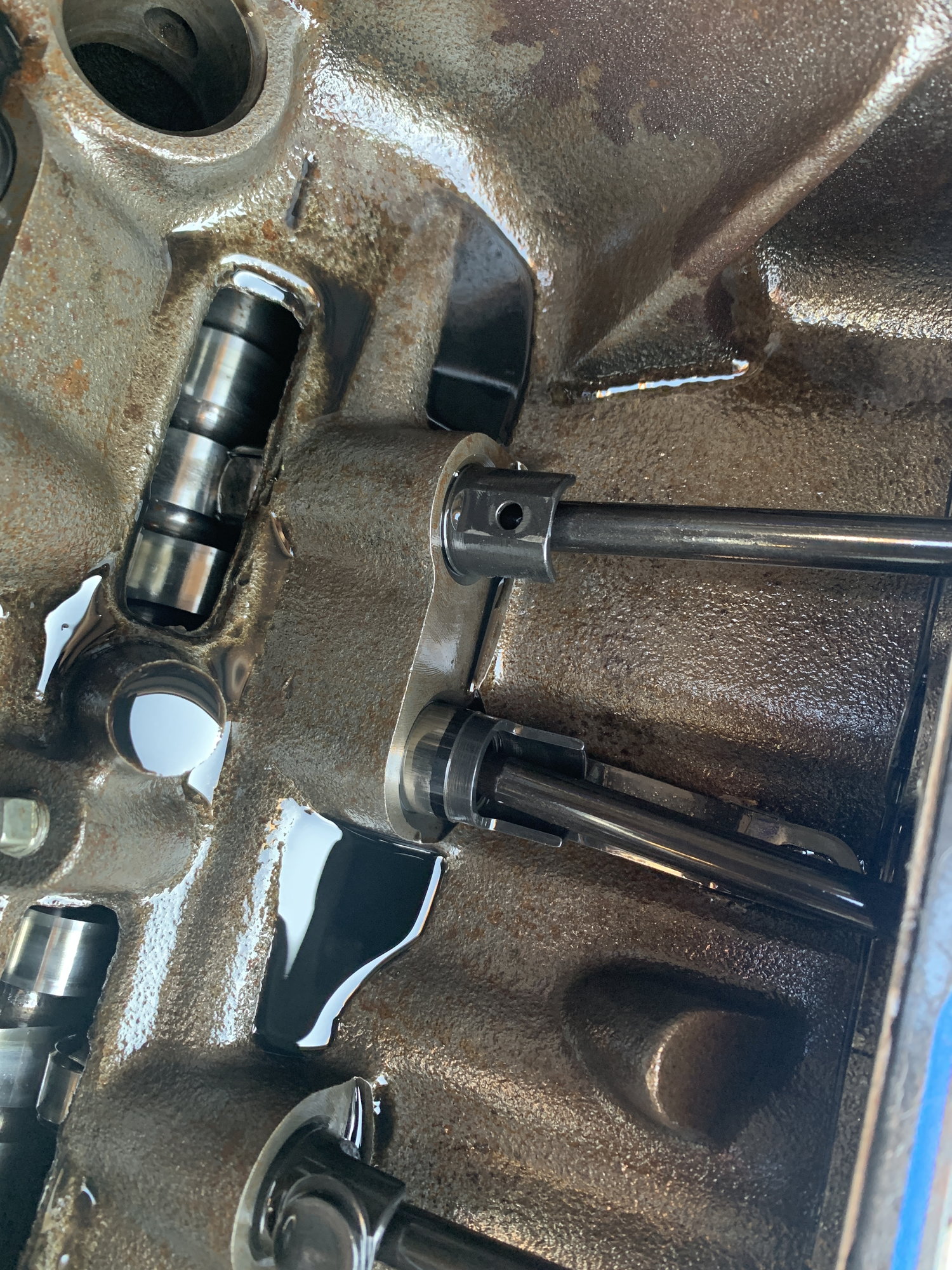

Missing link bar rivet and rotated lifters

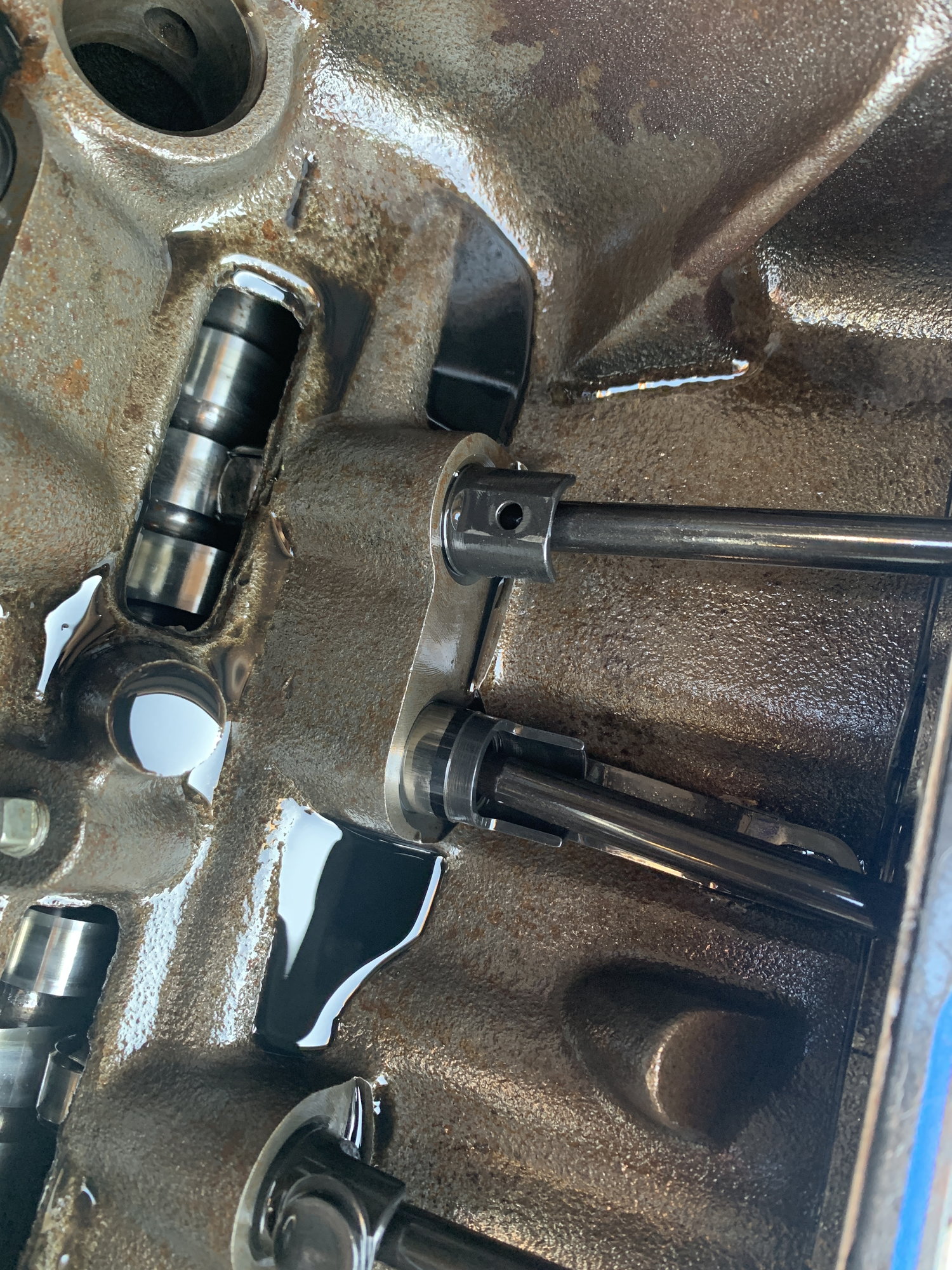

Square roller

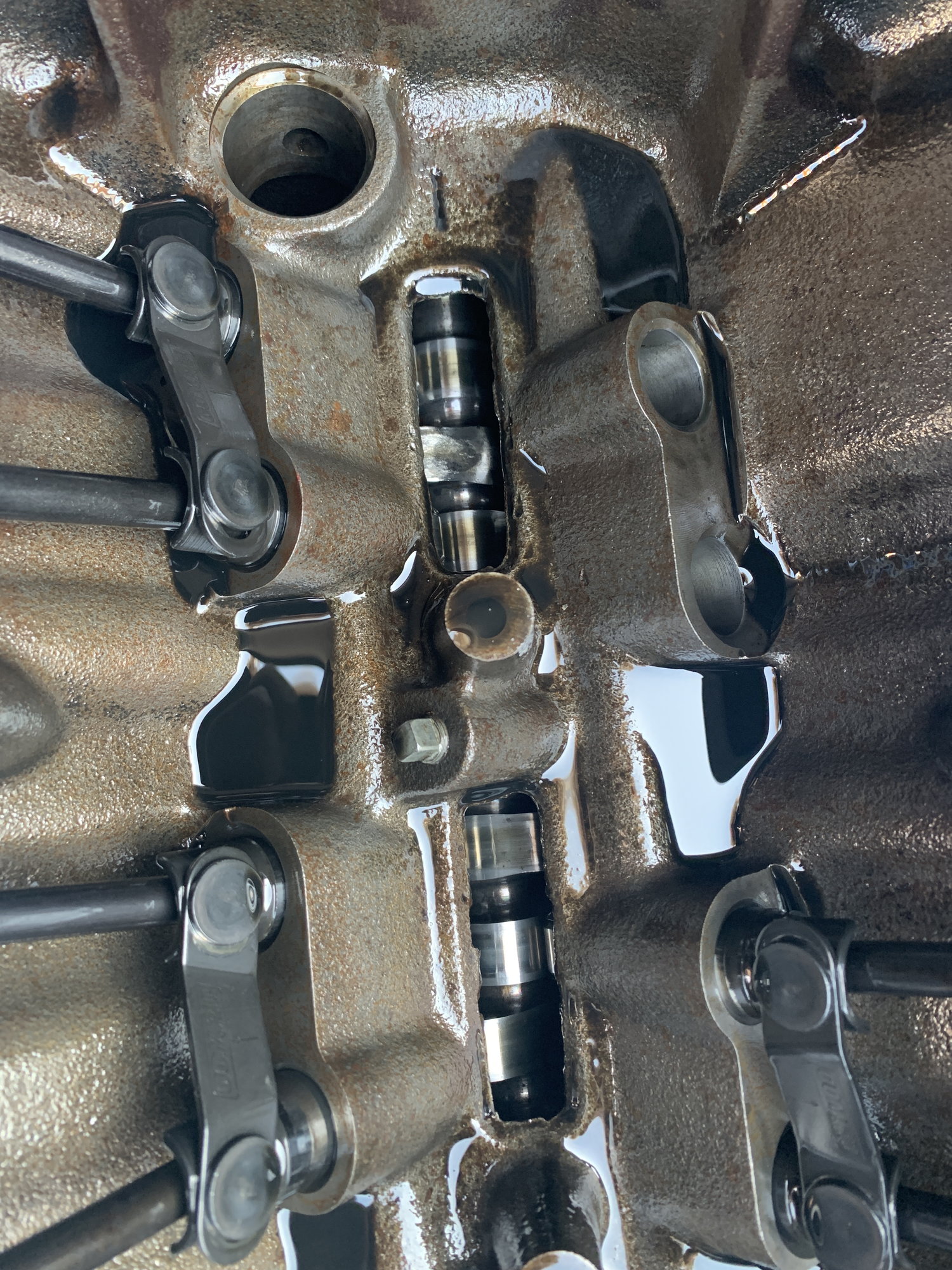

Gouged lobe

The engine is a Gen VI 502 block taken out to 540 with a callies crank and rods with 10.25:1 compression ratio and aluminium Dart Pro 1 355cc CNC heads.

It had a Lunati hydraulic roller cam 299/309 - 114 LSA and Comp Cams 15854-16 short travel lifters which came with a good recommendation.

Now I have looked to reorder the cam and lifters I see that this part number is recommended for the older series non OE hydraulic cam blocks. have I got the wrong lifters fitted and is that what caused the failure? the engine only had about 10 hours on it.

Missing link bar rivet and rotated lifters

Square roller

Gouged lobe

The engine is a Gen VI 502 block taken out to 540 with a callies crank and rods with 10.25:1 compression ratio and aluminium Dart Pro 1 355cc CNC heads.

It had a Lunati hydraulic roller cam 299/309 - 114 LSA and Comp Cams 15854-16 short travel lifters which came with a good recommendation.

Now I have looked to reorder the cam and lifters I see that this part number is recommended for the older series non OE hydraulic cam blocks. have I got the wrong lifters fitted and is that what caused the failure? the engine only had about 10 hours on it.

#5

Registered

#8

The other link bars / pins don't look particularly worn but I'll get them out for a proper look. I'd have thought 10 hours wasn't a lot of time in which catastrophic wear could occur?

I am not clear which way the oiling in the lifter galleries flows, is it front to back? in which case this would be the last lifter on this bank to receive oil?

Trying to understand the root cause here, and I am not sure of the sequence of events, as I see it the problem could be; -

a] Perhaps the needle rollers seized due to a manufacturing defect or poor oiling. could this be because the incorrect lifters were fitted, would early style ones in a late block not receive correct oiling because the oilways come into the lifter bores at a different point?

b] Maybe the link bar button popped off allowing the lifter to rotate and the roller to skid/lock on the cam. What function do the link bars perform? are they to stop the lifters popping out of the bore with a high lift cam or are they designed to stop rotation [surely the standard OE lifter type without link bars could rotate in that case]

Are hydraulic lifters just troublesome, I had Morels in my last engine and they were inconsistent; sometimes noisy / didn't always pump up. So this time I went with these comp Cams short travel ones after reading recommendations. are they rubbish too as 14 Apache says.

Thanks

Paul

#9

Registered

The link bars are to keep the lifters aligned with the camshaft.

The stock lifters use a different setup but still keep the lifters from rotating. The rollers have to stay aligned with the cam.

Might be the picture but the pushrods look like they are very close to the top of the lifter, almost touching ? The two failed lifters look like they have a lot of wear on the bodies. How do the others look ?

Just thinking out loud. I would certainly send the lifters back to Comp just to see what they say.

#10

Registered

Join Date: Jan 2007

Location: Murrayville Georgia

Posts: 1,818

Likes: 0

Received 893 Likes

on

320 Posts

from the look of it you have a heat problem on the two that failed. the bodies are black everywhere but the parts touching the lifter bore. none of the others look to be black at the top.