I have reversion but I shouldn't

#31

Registered

iTrader: (7)

I actually just went back and saw the jizz in the oil. Did you scrape that from under valve cover or top of heads. I just looks at oil color earlier but again have seen that also. I know you mentioned upon gasket inspection all appeared fine but double ck both sides of your intake gaskets. Can run a straight edge down both side your intake and heads also. I'm just throwing this out there andcsure you have but just trying to help.

#32

Gold Member

Join Date: Oct 2011

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

Trying to figure out why I am getting reversion when based on everything I know I shouldn't be. Most likely something I have done wrong, but I cannot figure out what.

Here are the engine specs

SBC

9.4:1 compression

Davis Unified Ignition (base timing set at 10 degrees)

Edelbrock e-tec 170 heads with 1.52 roller rockers

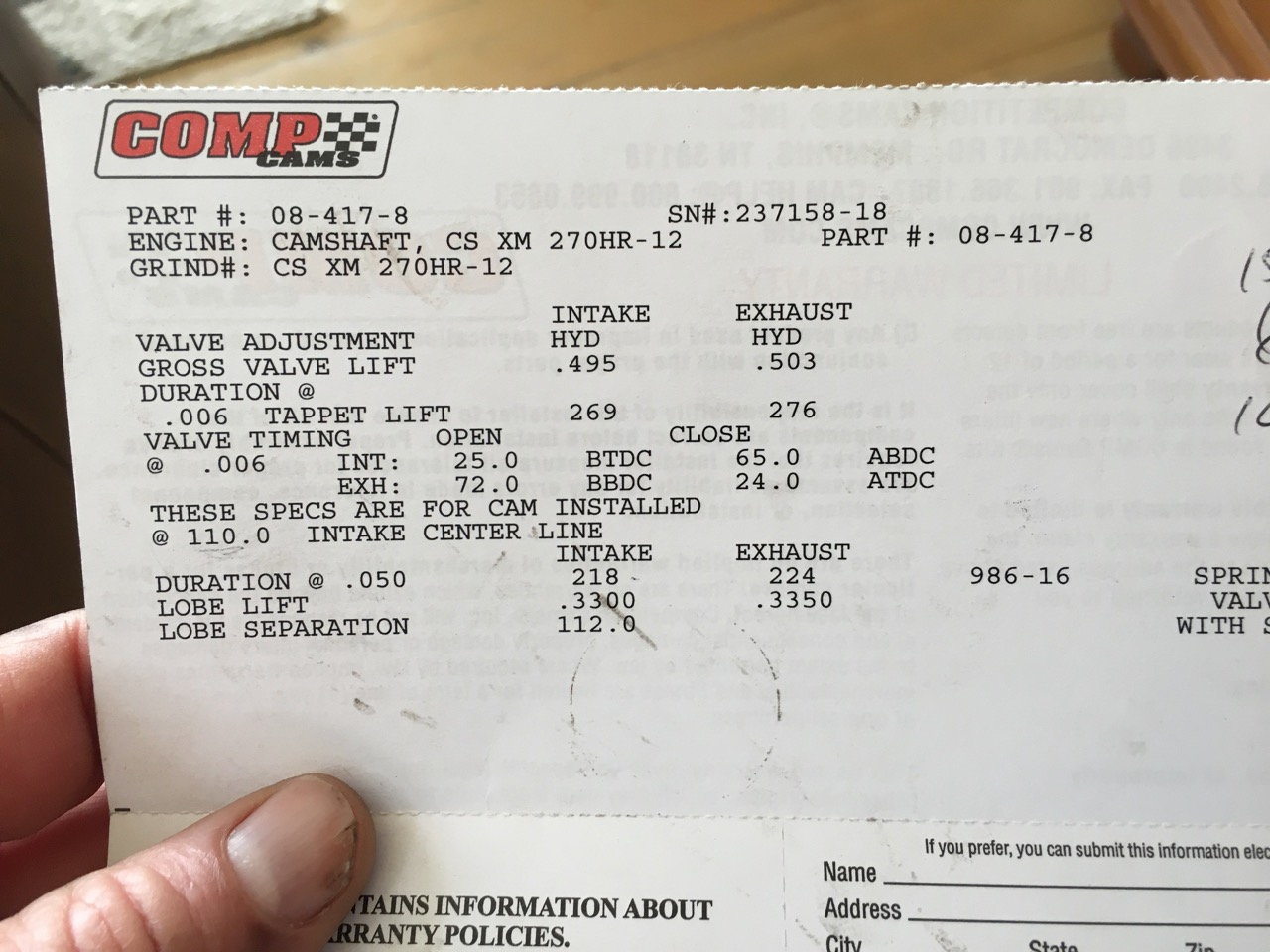

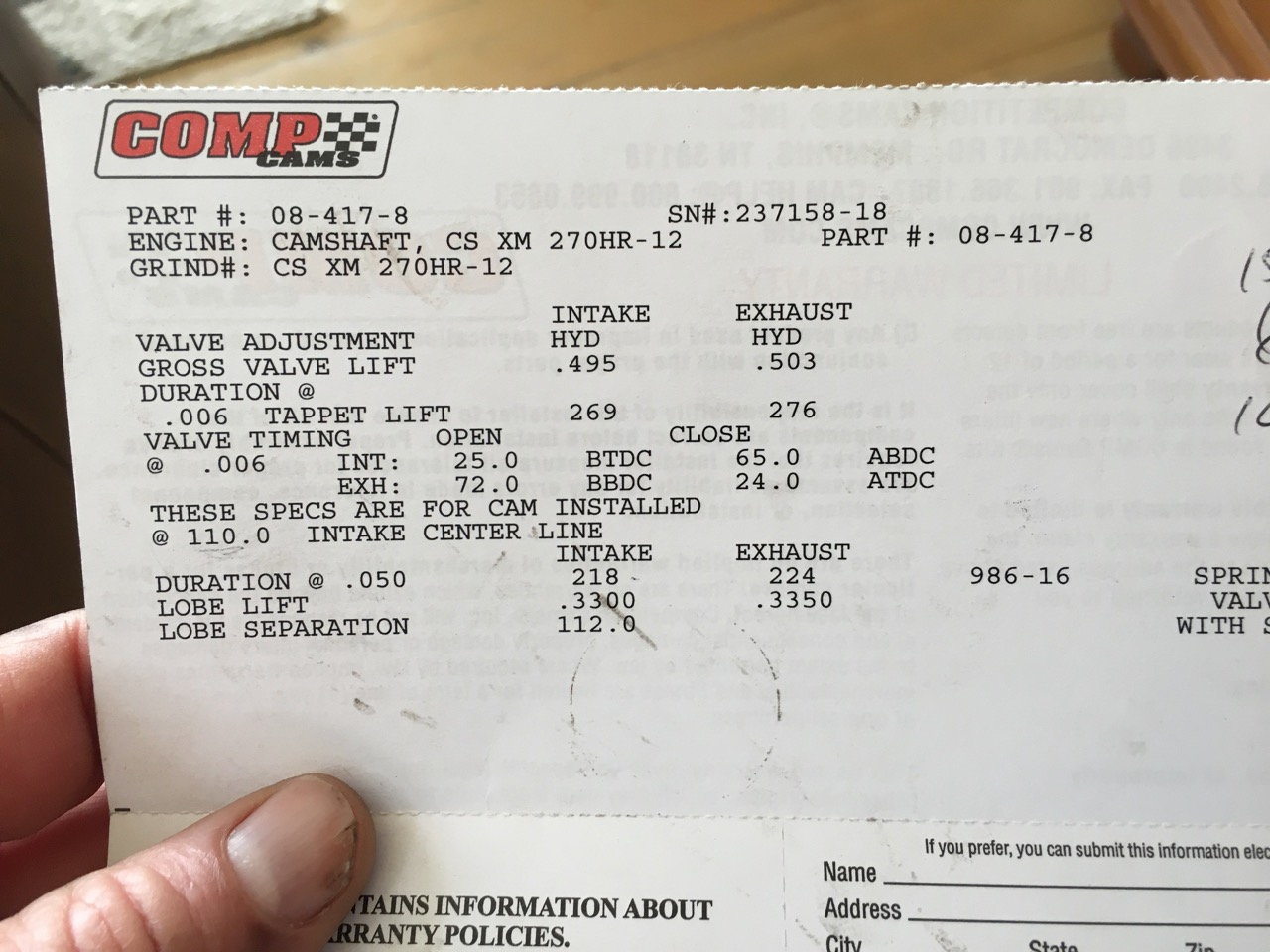

Comp Cams xms270hr cam

specs in attached picture

Brand New custom, very long risers from Stainless Marine (picture attached)

I am new to assembling engines. I purchased this short block directly from GM. I installed the cam and the heads etc etc. The cam was installed 'dot to dot'. I went through the steps to degree the cam. I was fuzzy on the process but had all the tools and got some numbers that told me I was good and left the cam straight up.

I went through the process to make sure that rocker arm geometry was right and got proper length pushrods.

The boat starts and runs with ease. I have not had it in the water yet.

Is there something I could have done wrong during cam installation that would cause this?

Any ideas on where to go from here would be greatly appreciated. I was thinking the boat was going to be in the water next weekend, now I am wondering if I am going to have to pull the engine again.

Here is a picture of my risers:

Here is my cam card:

Here is pictures of how much water is in my manifolds:

Thanks,

Russ

Here are the engine specs

SBC

9.4:1 compression

Davis Unified Ignition (base timing set at 10 degrees)

Edelbrock e-tec 170 heads with 1.52 roller rockers

Comp Cams xms270hr cam

specs in attached picture

Brand New custom, very long risers from Stainless Marine (picture attached)

I am new to assembling engines. I purchased this short block directly from GM. I installed the cam and the heads etc etc. The cam was installed 'dot to dot'. I went through the steps to degree the cam. I was fuzzy on the process but had all the tools and got some numbers that told me I was good and left the cam straight up.

I went through the process to make sure that rocker arm geometry was right and got proper length pushrods.

The boat starts and runs with ease. I have not had it in the water yet.

Is there something I could have done wrong during cam installation that would cause this?

Any ideas on where to go from here would be greatly appreciated. I was thinking the boat was going to be in the water next weekend, now I am wondering if I am going to have to pull the engine again.

Here is a picture of my risers:

Here is my cam card:

Here is pictures of how much water is in my manifolds:

Thanks,

Russ

stainless builds a great exhaust system

if it was me i would double gasket that flange and use a high heat gasket sealer on all sides of the gaskets

what happens is that you may think because you are installing a new gasket and cranking the clamp that your good to go but not really

if there is the slightest vacuum leak in the area it will and i repeat it will draw water back into that system and if you call stainless marine the owner named Jerry will confirm what i just said

another test to double check that flange area is to run the engine and spray alittle 2 stroke into the carb or air horn if it’s injected and see if you get a cloud lingering around that flange

#34

I put thread sealant on all the head studs.

I also sealed both side of the intake gasket at the water ports.

I checked tonight and my timing mark is spot on and cam centerline is 110 degrees which is spot on as well.

Sure would be totally like me to tear down the top of this motor when the real problem was just exhaust wasn't sealed properly. Wouldn't surprise me. Oh well, it's dark early these days and I'd rather be doing this than pacing back in forth in front of the sliding glass door waiting for spring.

Heads go back on tomorrow.

Thanks again for all the advice and suggestions.

I also sealed both side of the intake gasket at the water ports.

I checked tonight and my timing mark is spot on and cam centerline is 110 degrees which is spot on as well.

Sure would be totally like me to tear down the top of this motor when the real problem was just exhaust wasn't sealed properly. Wouldn't surprise me. Oh well, it's dark early these days and I'd rather be doing this than pacing back in forth in front of the sliding glass door waiting for spring.

Heads go back on tomorrow.

Thanks again for all the advice and suggestions.

#37

Registered

iTrader: (7)

That is a great post from activator40. I've never used Stainless Marine exhaust and only have heard and read great things about them however wasn't aware of the sealing issue. One thing I might recommend to them if this is such a reoccurring problem they might wanna have a warning label of such issue in with the clamps etc. Regardless it sounds like a relatively easy fix anyway.

#38

Registered

iTrader: (7)

Post #6 actually looks like gasket tear but would imagine from riser removal? Did you make any adjustments during install to fit transom outlets that may have fudged up the gasket. I could see where it wouldn't take much with a rather thin gasket. As mentioned sealing both sides of the gaskets is crucial. Not sure if you installed engine with risers or after but they gotta be a bit of a juggling act to mate manifold considering the size/weight. Slightest little screw up could destroy that gasket material rather easily. I wouldn't be afraid go a little on the heavy side with the sealer and once in place clamp and let sit til dry.

#39

You have pictures showing drops of water down the manifold side. Are there signs of water on the upstream side of the elbow/manifold collar area? If not the collar is the suspect. If there is, I bet it's a leak somewhere in the elbow section.

#40

definitely could be the seal at the risers. I did not spend much time there. Just installed the riser and tightened the clamp. I did see the gasket move around some but figured the clamp would pull it all together. Had no idea this was a spot to fuss over. Now I know. more information from the manufacturer would have been great here.

I called stainless marine and ordered a stack of the riser gaskets yesterday. Got the heads back on yesterday and plan on having it all back together this weekend.

Thanks again for all the great information. I'd be a little SOL without a site like this.

Russ

I called stainless marine and ordered a stack of the riser gaskets yesterday. Got the heads back on yesterday and plan on having it all back together this weekend.

Thanks again for all the great information. I'd be a little SOL without a site like this.

Russ