I have reversion but I shouldn't

#61

Registered

iTrader: (7)

Just making sure the heads are compatible with what gen short block OP purchased. Great heads btw. I did catch the NEW short block from GM. Marine or auto? I'll take a guess probably auto. Might be worthy of finding out the rod and main clearances on what you purchased. Just an FYI.

#62

The manifolds pressure checked ok. Just in case, I installed some EMI thunder manifolds I have and ran the engine again without the risers and still have water in the exhaust manifolds.

The heads should be fine with this block as they are vortec style heads and this was a vortec marine long block from GM.

To pressurize the entire system I assume that I can just adapt my garden hose to the inlet on my crossover pipe.....we have a **** ton of pressure.....and let her rip. At that point, what do I watch for. I am guessing that I will or won't see water coming into the manifolds, but not sure what that would tell me. Any advice on what to watch or listen for hear would help.

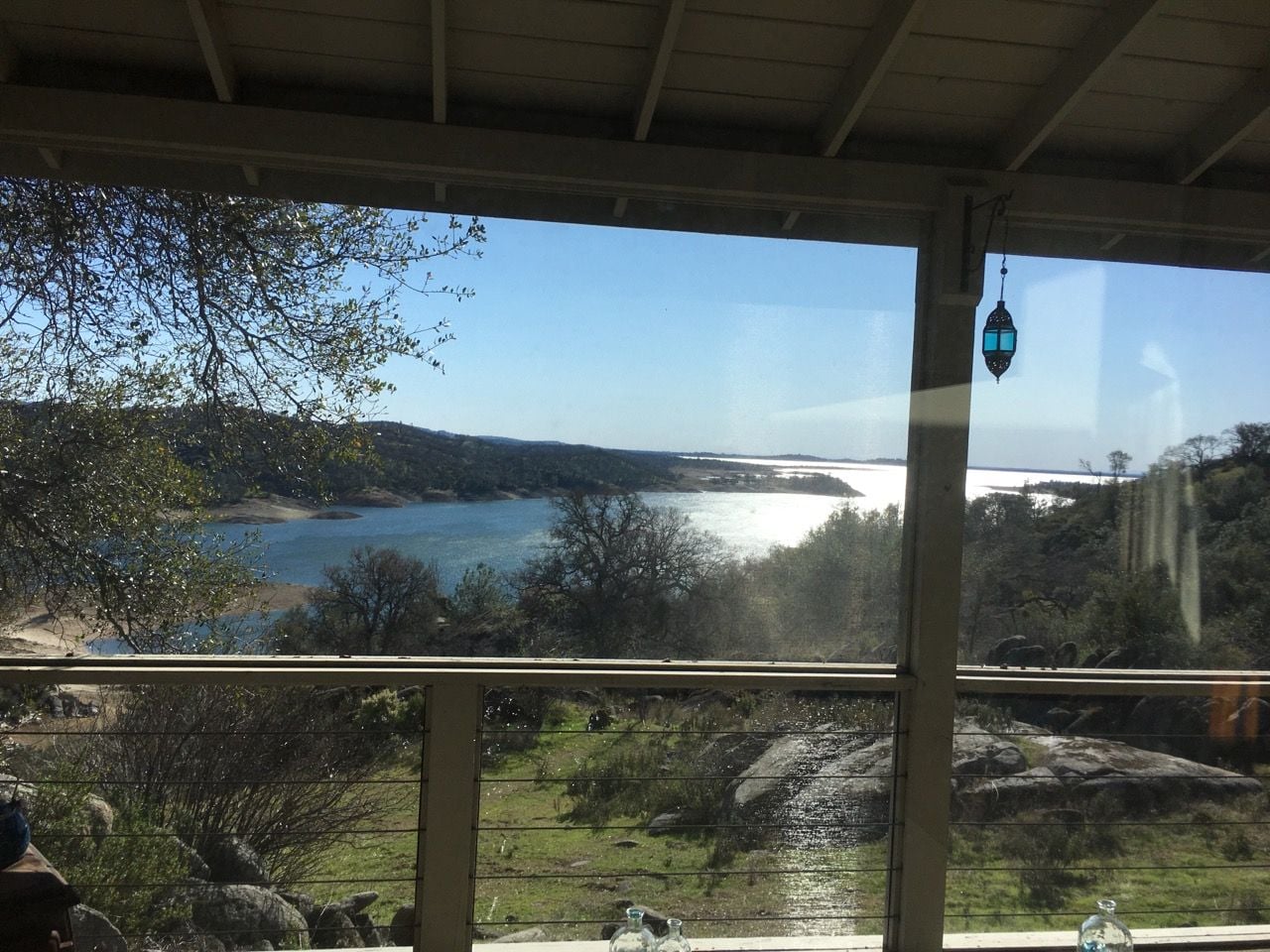

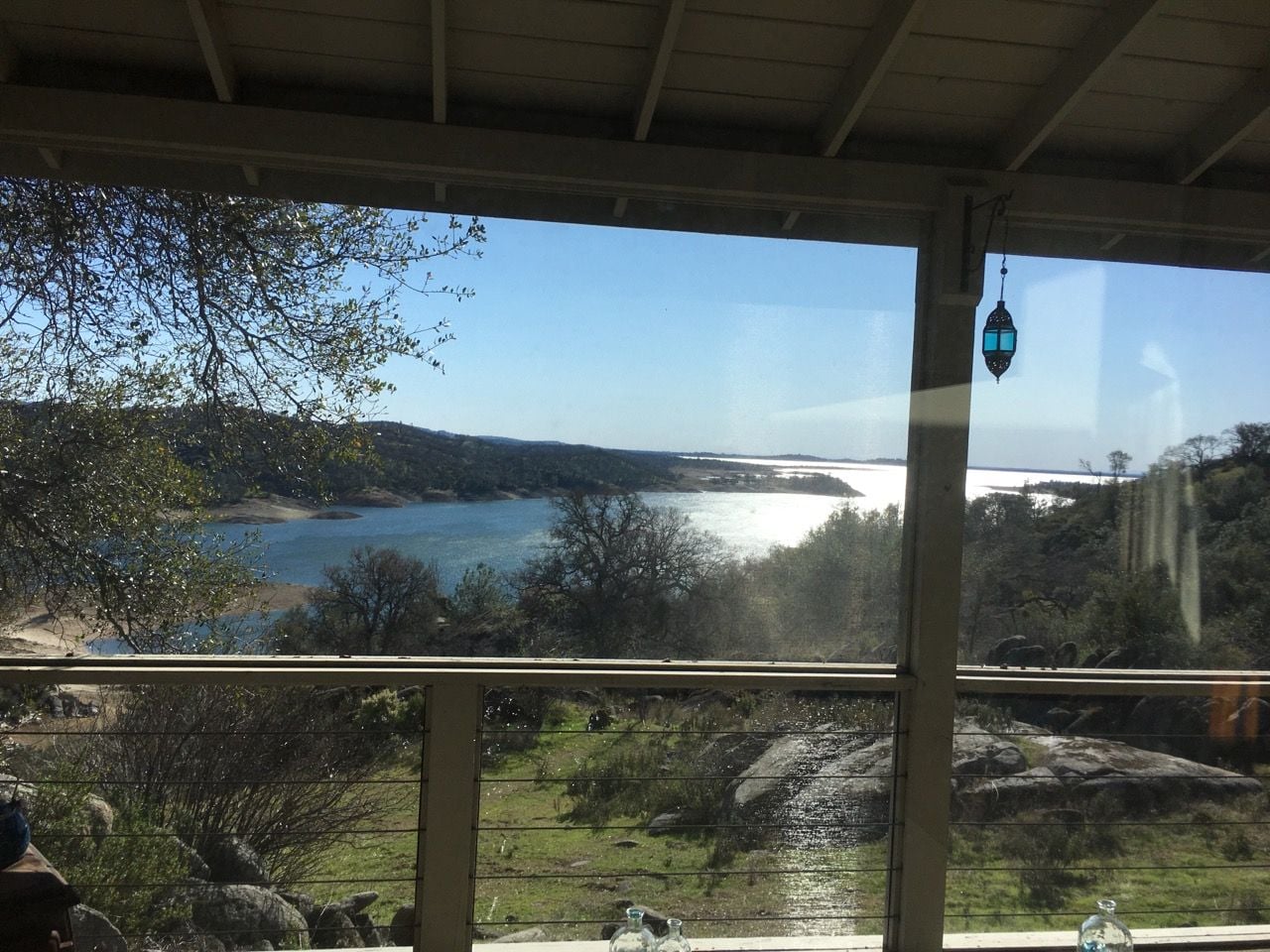

Here is a picture from my living room window of where I should be today.

Thanks again.

The heads should be fine with this block as they are vortec style heads and this was a vortec marine long block from GM.

To pressurize the entire system I assume that I can just adapt my garden hose to the inlet on my crossover pipe.....we have a **** ton of pressure.....and let her rip. At that point, what do I watch for. I am guessing that I will or won't see water coming into the manifolds, but not sure what that would tell me. Any advice on what to watch or listen for hear would help.

Here is a picture from my living room window of where I should be today.

Thanks again.

#64

Registered

iTrader: (3)

Not sure if its the "correct" way but when I pressure tested mine. (I have a crossover no recirc pump) I plugged the 2 houses going from the thermostat cover to the exhaust, then made a schrader valve setup with a pvc fitting and gauge where the water normally goes into the crossover. As far as I know max water pressure should be about 30 psi, so I pressurized the motor to 35 psi with air, let it sit for a while and checked to see if it had lost any pressure.

#66

Registered

iTrader: (1)

As far as the milky oil:

What intake gaskets and bolts did you use ? Part#'s please.

What did you use to seal the head studs (btw, why studs ?) to the block and how did you install them ?

What intake gaskets and bolts did you use ? Part#'s please.

What did you use to seal the head studs (btw, why studs ?) to the block and how did you install them ?

#67

Intake gasket part number: Edelbrock 7235. The hardware was pretty basic black oxide bolts from the hardware store that I thought looked cool with the setup. They were torqued in sequence to, as I recall, 12 ft/lbs.

I used the ARP thread sealant on all the studs and installed them as per the manual. Just hand tight with the stud into the block, then apply ARP installation lubricant to the washer and then torque the nuts in sequence in three steps to 80 ft/lbs.

It would be great if I did something stupid here that would be an easy fix. If you see it, let me know.

Thanks

I used the ARP thread sealant on all the studs and installed them as per the manual. Just hand tight with the stud into the block, then apply ARP installation lubricant to the washer and then torque the nuts in sequence in three steps to 80 ft/lbs.

It would be great if I did something stupid here that would be an easy fix. If you see it, let me know.

Thanks

#68

Registered

I'd test the engine by making up a gauge and valve for the cooling water inlet, then clamping the cooling hoses that go to the exhaust manifolds. Put about 13 or 15 psi in there. Listen for hissing at the exhaust, valve covers and carburetor. Turn the engine over manually while pressurized. Leaks can come from various places depending on valve positions.

#70

Registered

iTrader: (7)

I've always just used Permatex thread sealant. Had an external head bolt or two leak on occasion however they ended up sewing themselves shut by end of dyno session or a little time operating the engine (basically like Tinkerer mentioned). Whether there were any bolts leaking under the valve covers or not I have no clue. In fact years ago I even used just high temp silicone. Just a little messier when removing bolts down the road but very flexible when retorqing. A lot of sealants including permatex thread sealant harden to much and I don't care for that.

What do you use Mike and your thoughts on the hardness of the sealant.

What do you use Mike and your thoughts on the hardness of the sealant.

Last edited by getrdunn; 02-23-2020 at 10:43 AM.