Cylinder head/intake venting

#1

Registered

Thread Starter

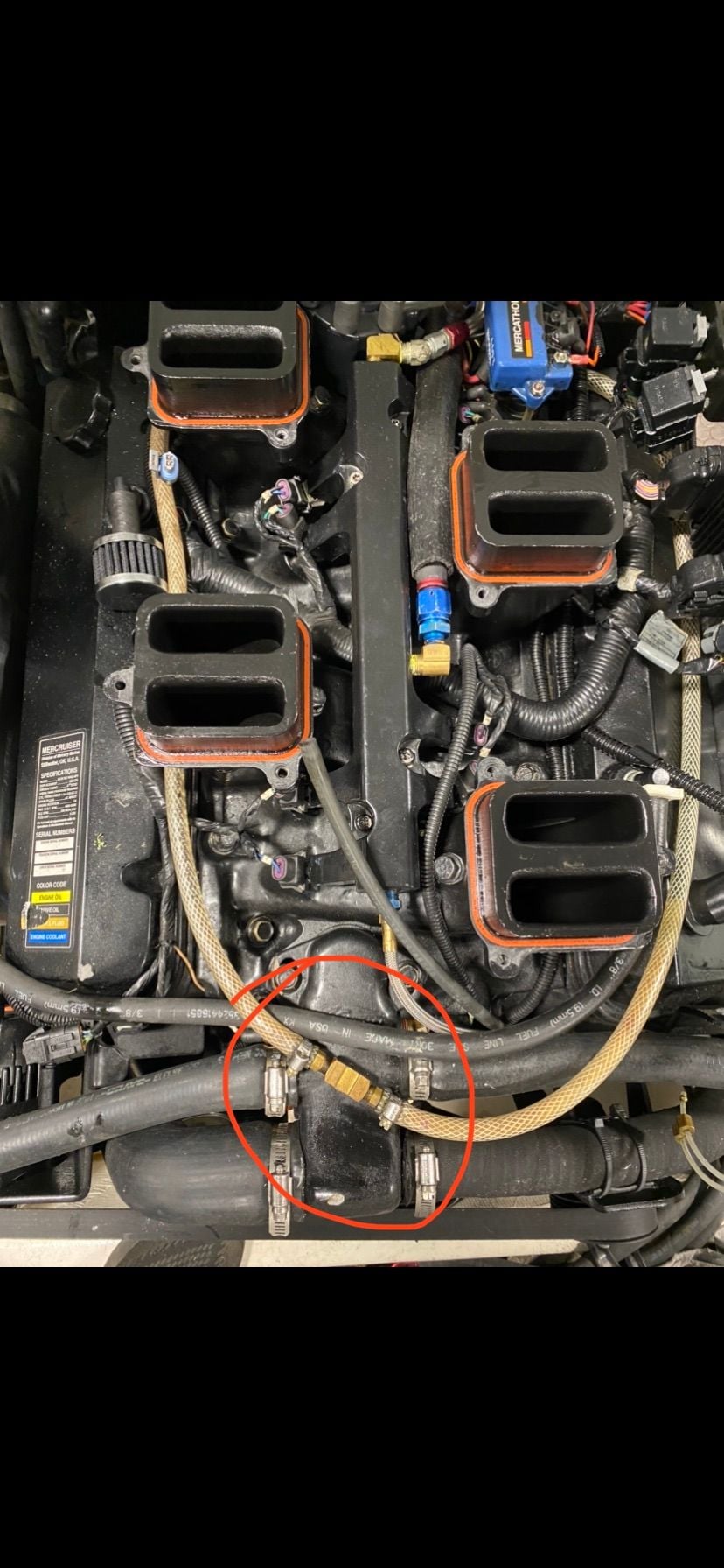

Venting the rear intake water crossover on BBC or not?? Ive rebuilt my 502 mags. They are now 509's pushing 610hp. Ive removed the circ pumps from the system & installed crossovers with thermostats. Im running Dart air gap intakes. What are you guys doing with your builds? some other hurdles Im trying to get over are, water pressure dumps? do I need to or not? running solely off bravo style, Harden Marine SS body pumps. Oil thermostat systems. My new coolers are very efficient. I need the oil to get to temp & on a test stand I cant get over 60*. What styles & plumbing are you using? 38* & snow today, wtf?.. lol

Thanks in advance for any help!

Thanks in advance for any help!

The following users liked this post:

NautiB (05-10-2020)

#4

The intake I took off my 502 mag mpi was drilled for the venting of the rear water ports and they were plumbed to the thermostat housing, I don't think it was a good way of doing it because the brass fitting were corroded closed, I feel do to low flow. The modded intake I put on was not drilled so I drilled it and ran -4 hose off each side and twined them and tied them into my exit bulkhead for my intercooler.

The following users liked this post:

NautiB (05-09-2020)

#5

Registered

Thread Starter

941, did you add any type of one way valve to prevent any back flow towards the intake or do you feel there is adequate pressure & flow so its not a concern. I was wondering about teeing them into the small hose (1/4") going from exh manifold to tail on my merc/gill set up.

Curious, was there any salt water on your set up that may have contributed to your fittings clogging up, or your pretty sure it was a low flow issue?

Curious, was there any salt water on your set up that may have contributed to your fittings clogging up, or your pretty sure it was a low flow issue?

#6

Registered

The intake I took off my 502 mag mpi was drilled for the venting of the rear water ports and they were plumbed to the thermostat housing, I don't think it was a good way of doing it because the brass fitting were corroded closed, I feel do to low flow. The modded intake I put on was not drilled so I drilled it and ran -4 hose off each side and twined them and tied them into my exit bulkhead for my intercooler.

The following users liked this post:

NautiB (05-10-2020)

#7

Not sure, I am in salt water but I flush with salt away every time she goes in the water. The fittings in my intercooler (stainless into aluminum) came apart by just wiggling the hose. I cut them and welded new stainless 90's on them. Makes sense what sutphen 30 is saying because the other intakes I have are opened open more around the water jacket then just a drilled hole tapped.

#9

Platinum Member

iTrader: (6)

I did it on my Whipple motors, I drilled and tapped a pair of -4 fittings on each side and run them into a -4 to -6 Y connector and dump it out the side discharge

The following users liked this post:

NautiB (05-12-2020)

#10

Registered

Not sure, I am in salt water but I flush with salt away every time she goes in the water. The fittings in my intercooler (stainless into aluminum) came apart by just wiggling the hose. I cut them and welded new stainless 90's on them. Makes sense what sutphen 30 is saying because the other intakes I have are opened open more around the water jacket then just a drilled hole tapped.