Cam degree calculation questions

#11

Registered

Thread Starter

Depends.

using + and - on valve events can cause confusion. It is always more "accurataccand prevents confusion and math errors to list them as

X degrees BTDC

X degrees ATDC

X degrees BBDC

X degrees ABDC

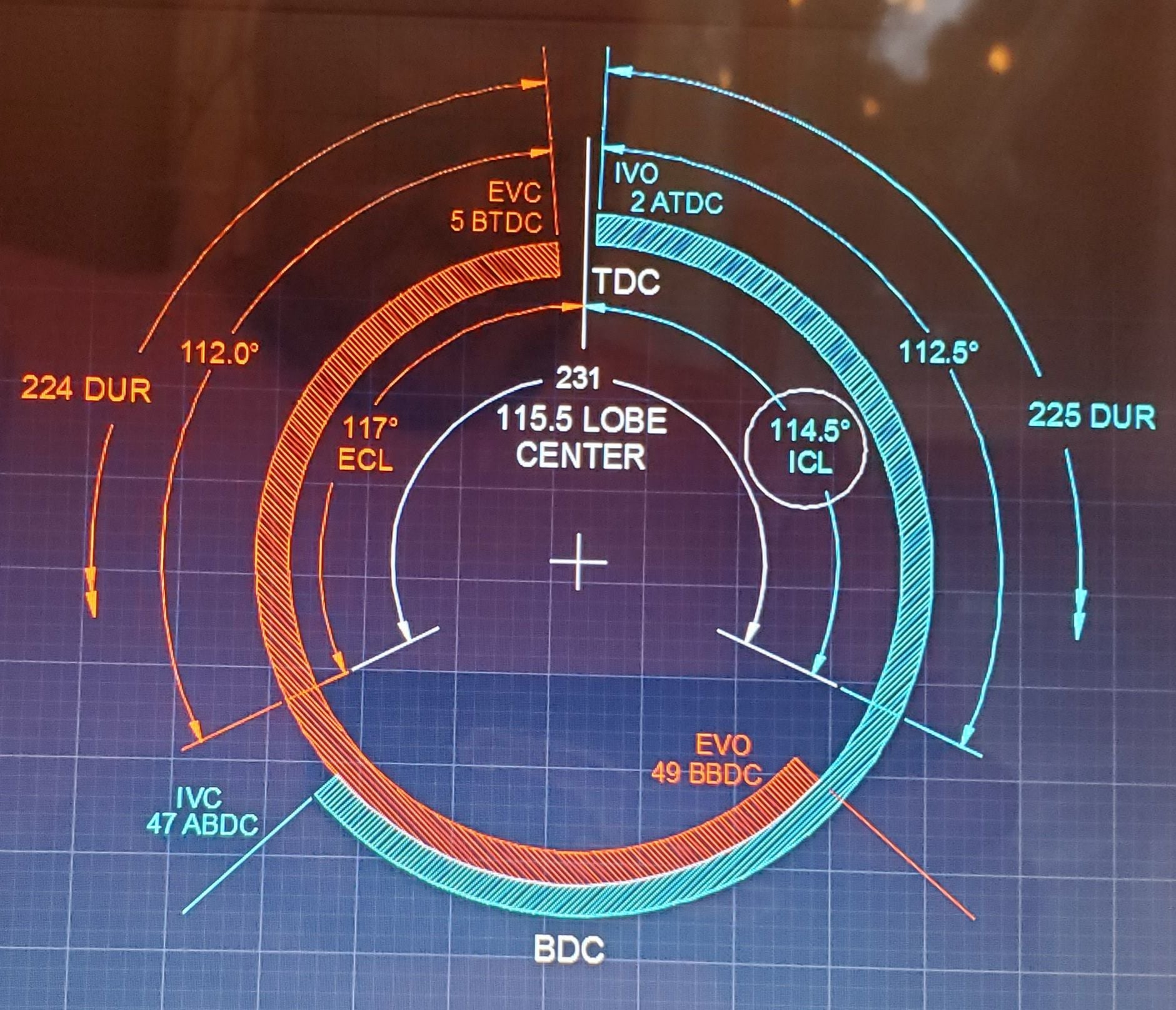

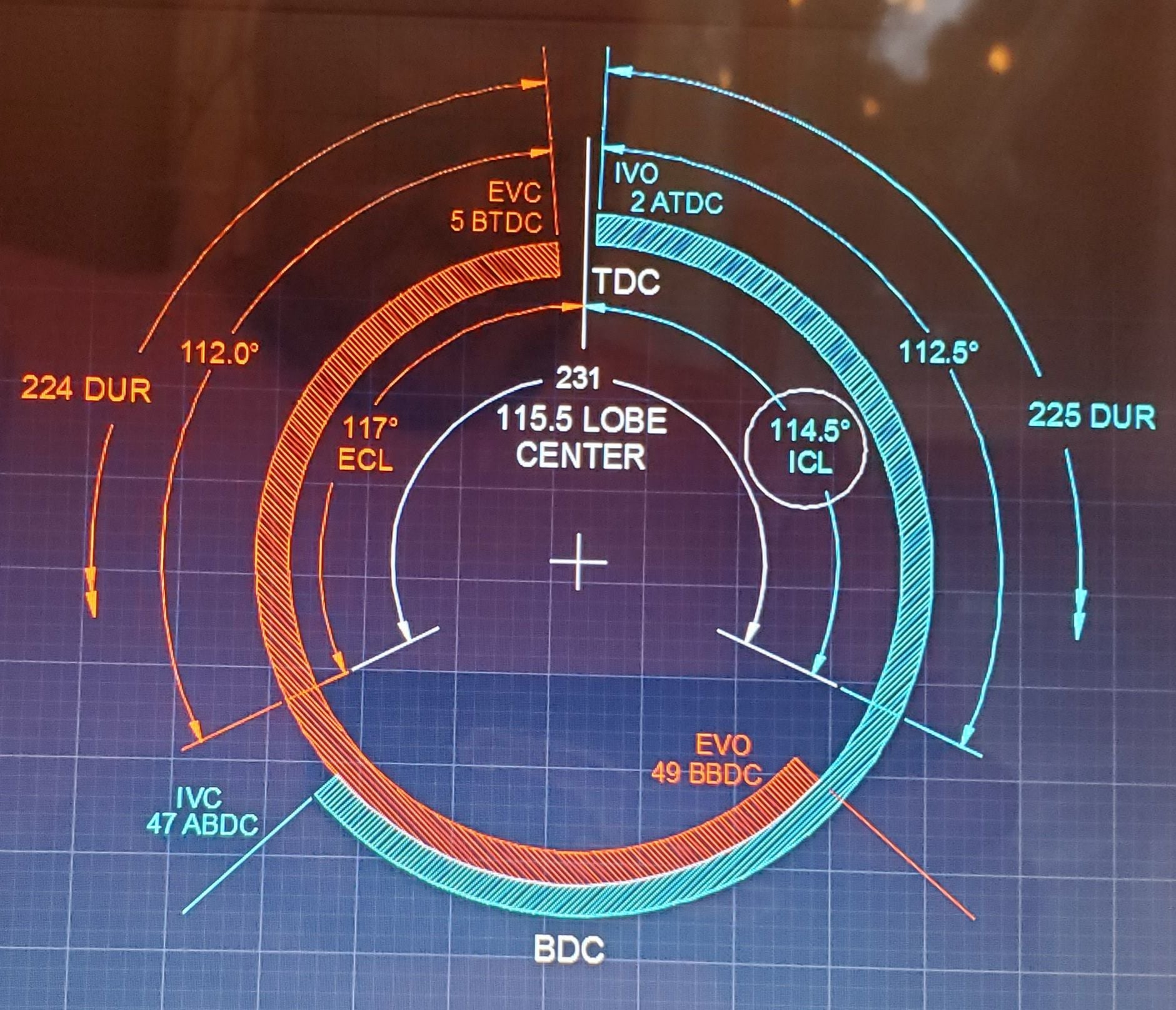

Here's my math from your numbers. Correct me where I'm misinterpreting your readings.

your intake opens at 2 ATDC (START COUNTING)

turn 178 to BDC

It closes at 47 ABDC

That is 178 + 47 = 225 duration.

centerline would be 112.5 + 2 = 114.5 ICL

your intake opens at 2 BTDC

Turn 180 to BDC

it closes at 47 ABDC

That is 2 + 180 + 47 = 229 duration

Centerline would be 114.5 - 2 = 112 5 ICL

As far as how cams are ground, and how timing sets are marked, I've seen them every way imaginable.

If you use a mercruiser part number cam and a mercruiser part number timing set, you MAY be safe to install straight up,, but I've even caught that kind of stuff being off (due to supplier changes).

My rule of thumb..

If it is a Japanese/Korean/German car, and you are using oem parts,, then trust the marks..

If it is ON or FOR an American auto engine,, then pull out the piston stops (for the TDC mark on the balancer), the degree wheel,, and the indicator (for the valve timing).

using + and - on valve events can cause confusion. It is always more "accurataccand prevents confusion and math errors to list them as

X degrees BTDC

X degrees ATDC

X degrees BBDC

X degrees ABDC

Here's my math from your numbers. Correct me where I'm misinterpreting your readings.

your intake opens at 2 ATDC (START COUNTING)

turn 178 to BDC

It closes at 47 ABDC

That is 178 + 47 = 225 duration.

centerline would be 112.5 + 2 = 114.5 ICL

your intake opens at 2 BTDC

Turn 180 to BDC

it closes at 47 ABDC

That is 2 + 180 + 47 = 229 duration

Centerline would be 114.5 - 2 = 112 5 ICL

As far as how cams are ground, and how timing sets are marked, I've seen them every way imaginable.

If you use a mercruiser part number cam and a mercruiser part number timing set, you MAY be safe to install straight up,, but I've even caught that kind of stuff being off (due to supplier changes).

My rule of thumb..

If it is a Japanese/Korean/German car, and you are using oem parts,, then trust the marks..

If it is ON or FOR an American auto engine,, then pull out the piston stops (for the TDC mark on the balancer), the degree wheel,, and the indicator (for the valve timing).

The negatives are where I threw you I know. Intake was atdc and needs to be a negative. Minus a minus becomes a positive. That's why you see me write it one way in one formula and different in another. Confusing. You're right. I'm consolidating different people's methods until I've got it fine tuned. I'm pretty confident in my measurements and calculations now.

Thanks to everyone that stuck around and saw me through till I got it right. Not trying to close this down if anyone has anything to add.

Billk, still would live to see what you come up with.

Last edited by HawkX66; 08-21-2021 at 11:53 AM.

#12

Platinum Member

I still say you are installed almost "straight up" rather than the +6 or +9 that Merc specs them. Again, I believe ICL of 109 is where it's "supposed to be".

#13

Registered

Thread Starter

Let's say I was, and I probably am, how would you install the cam? I mean physically from step one. On mine everything except the timing set is stock. Dot to dot leaves me 2° retarded, it seems like I'd have to advance it back to where it caused all my problems to get the 109. Is that pic something you made using my measurements?

Last edited by HawkX66; 08-21-2021 at 07:56 PM.

#14

Platinum Member

Those are your measurements.

If your measurements are accurate, then your cam is 1 degree advanced.

I keep reading that Merc specs that cam on a 109 ICL which is 5.5 degrees more advanced than you've got it.

Offset bushings (for the cam sprocket) can be used. A bushing that offsets the cam 2 degrees equates to 4 crank degrees..

Lower sprockets with multiple keyway can be used.

It doesn't hurt my feelings where you decide to put your cam,, but I do want you to be sure that you know where it is.

On a single engine cruiser, you don't really want to soften the midrange torque in exchange for a little more up top. Or at least I wouldn't think so.

Now, the way I understand it, you never knew where the cam was originally installed. This time you're gonna know exactly where it is.

I don't know if your heads are bolted down and torqued yet, but I do hope that once you get the cam where you want it, that you run clay snakes across a piston and bolt on a head (using an old gasket) install some lightweight testing valvesprings, oil up and bleed the lifters and drop em in, pushrods, zero lash the rockers and slowly turn the motor over at least 2 full rotations. Watch the lifters and make certain that they don't collapse any (which is the reason you use test springs and bleed the air out of the lifters..).

Then (and only then) will you know your true piston to valve clearance when you measure the thin sections of the smashed clay snakes.

If your measurements are accurate, then your cam is 1 degree advanced.

I keep reading that Merc specs that cam on a 109 ICL which is 5.5 degrees more advanced than you've got it.

Offset bushings (for the cam sprocket) can be used. A bushing that offsets the cam 2 degrees equates to 4 crank degrees..

Lower sprockets with multiple keyway can be used.

It doesn't hurt my feelings where you decide to put your cam,, but I do want you to be sure that you know where it is.

On a single engine cruiser, you don't really want to soften the midrange torque in exchange for a little more up top. Or at least I wouldn't think so.

Now, the way I understand it, you never knew where the cam was originally installed. This time you're gonna know exactly where it is.

I don't know if your heads are bolted down and torqued yet, but I do hope that once you get the cam where you want it, that you run clay snakes across a piston and bolt on a head (using an old gasket) install some lightweight testing valvesprings, oil up and bleed the lifters and drop em in, pushrods, zero lash the rockers and slowly turn the motor over at least 2 full rotations. Watch the lifters and make certain that they don't collapse any (which is the reason you use test springs and bleed the air out of the lifters..).

Then (and only then) will you know your true piston to valve clearance when you measure the thin sections of the smashed clay snakes.

The following users liked this post:

SB (08-21-2021)

#15

Registered

iTrader: (1)

Great info ^^^^^

#16

Registered

Thread Starter

Those are your measurements.

If your measurements are accurate, then your cam is 1 degree advanced.

I keep reading that Merc specs that cam on a 109 ICL which is 5.5 degrees more advanced than you've got it.

Offset bushings (for the cam sprocket) can be used. A bushing that offsets the cam 2 degrees equates to 4 crank degrees..

Lower sprockets with multiple keyway can be used.

It doesn't hurt my feelings where you decide to put your cam,, but I do want you to be sure that you know where it is.

On a single engine cruiser, you don't really want to soften the midrange torque in exchange for a little more up top. Or at least I wouldn't think so.

Now, the way I understand it, you never knew where the cam was originally installed. This time you're gonna know exactly where it is.

I don't know if your heads are bolted down and torqued yet, but I do hope that once you get the cam where you want it, that you run clay snakes across a piston and bolt on a head (using an old gasket) install some lightweight testing valvesprings, oil up and bleed the lifters and drop em in, pushrods, zero lash the rockers and slowly turn the motor over at least 2 full rotations. Watch the lifters and make certain that they don't collapse any (which is the reason you use test springs and bleed the air out of the lifters..).

Then (and only then) will you know your true piston to valve clearance when you measure the thin sections of the smashed clay snakes.

If your measurements are accurate, then your cam is 1 degree advanced.

I keep reading that Merc specs that cam on a 109 ICL which is 5.5 degrees more advanced than you've got it.

Offset bushings (for the cam sprocket) can be used. A bushing that offsets the cam 2 degrees equates to 4 crank degrees..

Lower sprockets with multiple keyway can be used.

It doesn't hurt my feelings where you decide to put your cam,, but I do want you to be sure that you know where it is.

On a single engine cruiser, you don't really want to soften the midrange torque in exchange for a little more up top. Or at least I wouldn't think so.

Now, the way I understand it, you never knew where the cam was originally installed. This time you're gonna know exactly where it is.

I don't know if your heads are bolted down and torqued yet, but I do hope that once you get the cam where you want it, that you run clay snakes across a piston and bolt on a head (using an old gasket) install some lightweight testing valvesprings, oil up and bleed the lifters and drop em in, pushrods, zero lash the rockers and slowly turn the motor over at least 2 full rotations. Watch the lifters and make certain that they don't collapse any (which is the reason you use test springs and bleed the air out of the lifters..).

Then (and only then) will you know your true piston to valve clearance when you measure the thin sections of the smashed clay snakes.

I just got my head back last night with a new valve seat. They won't go back on permanently until I get this right and I've checked the PTV correctly.

So for me to move the ICL from where it is at 114.5° to 109°, am I correct in saying I need to move my adjustable crank sprocket another 5.5° advanced? That would have me putting it at 8° how it's marked.

Last edited by HawkX66; 08-22-2021 at 08:08 AM.

#18

Registered

Thread Starter

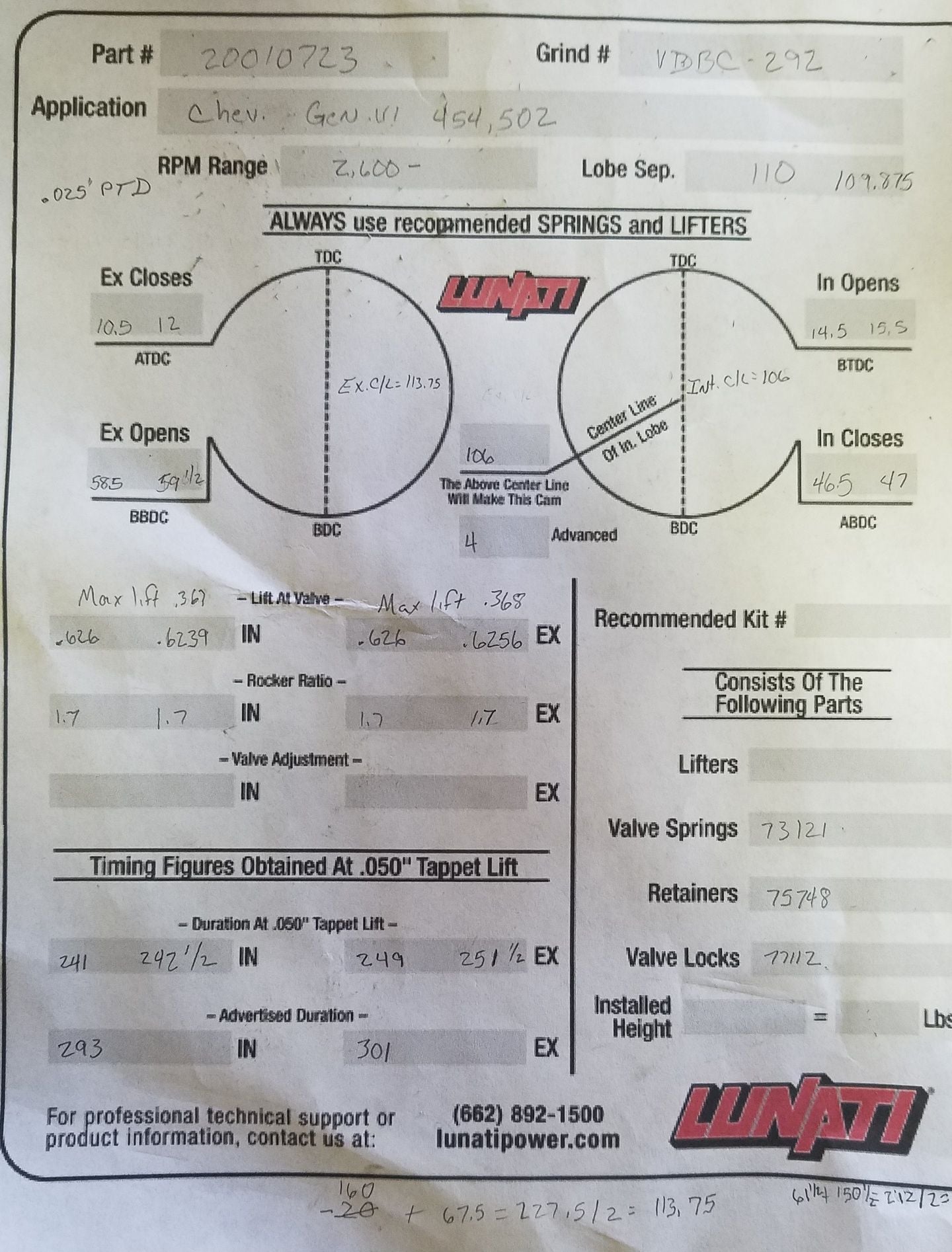

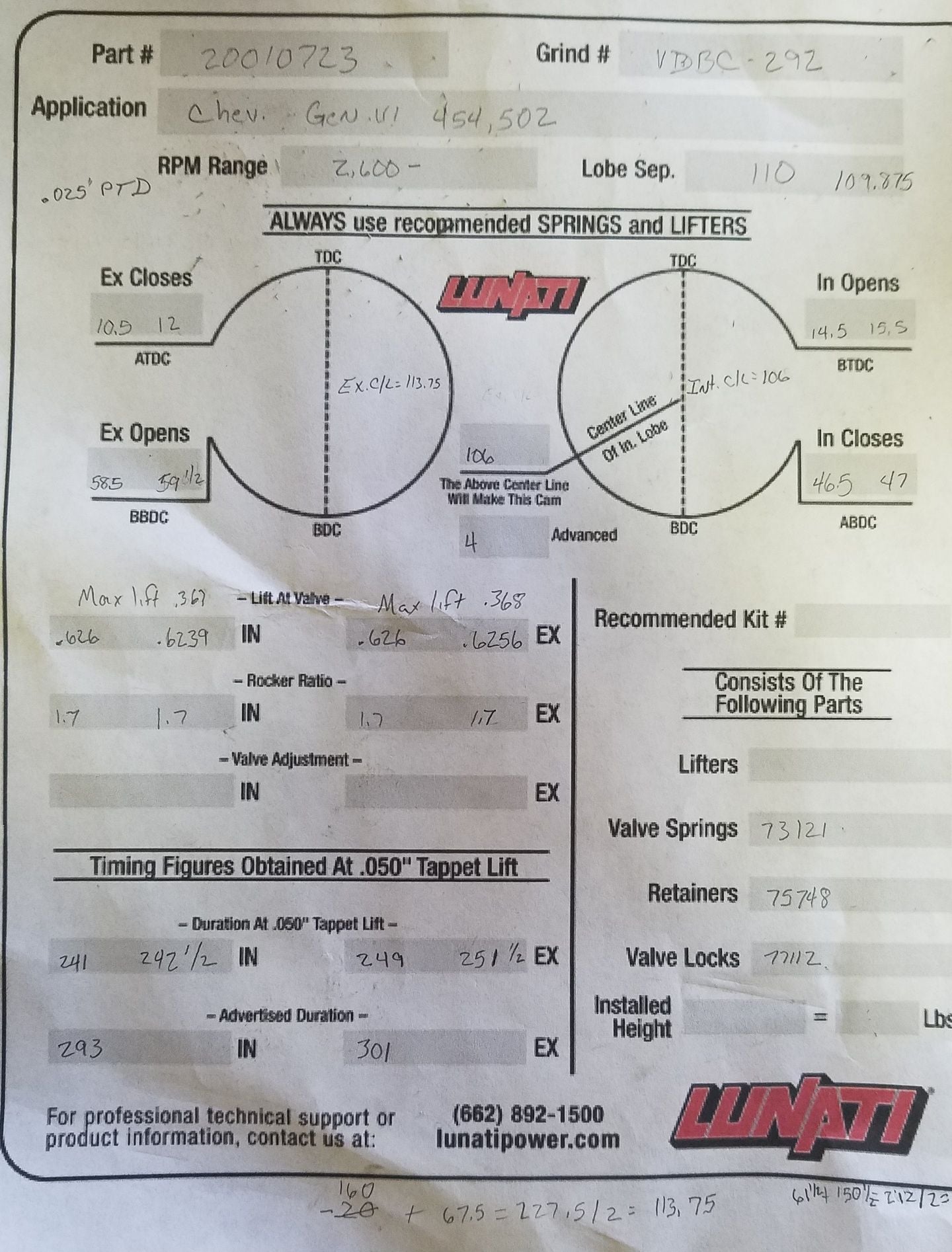

To add to my last post, this is what's confusing me with this cam. My Lunati cam was ground with 4° advance. I had to install it dot to dot. Not 4° advanced with the adjustable timing set.

here are my calculations when I did that. Cam card and my hand written notes. Where you see two numbers written for IVO etc, one is from the card and the other is my measurements.

here are my calculations when I did that. Cam card and my hand written notes. Where you see two numbers written for IVO etc, one is from the card and the other is my measurements.

#19

Platinum Member

iTrader: (6)

I put a Lunati hrdo roller in the 427 for the Vette, it was ground 4* advanced and I installed it straight up as per the instructions