1979 Rogers Jet Boat project

#1

Registered

Thread Starter

Well I know this is not a offshore big kid boat, here is my boat project.

The following day my neighbor and I flushed both fuel tanks. Orange sludge came out, about 12 gallons worth on a boat "that was stored empty", kept flushing till the gas coming out was as clear and clean as the gas going in, the old gas and the new gas would not mix.... nothing like tossing 20 gallons of good gas....

New filter in, I think I will replace the lines from the fuel tank to the selector, seems like cheap insurance at $1.50/ft... last think I want to do is plug up my system while out on the lake to save $15. Thinking I should replace the coolant feed lines.... they are looking rather old.

I will need to rebuild the holly that is on there, once I figure out what I have. Good news though, little bit of fresh 91 in a can pumped into the car and that 454 comes to life, carb leaks out of every seal but sounds healthy.

While trying to get her started there was a minor issue, either the former owners miss wired her or I have a short. The tach output from the MSD street fire is shorted to GND, once it was removed from the system, it all worked. One more thing to look into.

Bringing her home on day 1

"how you leave the battery" this will change

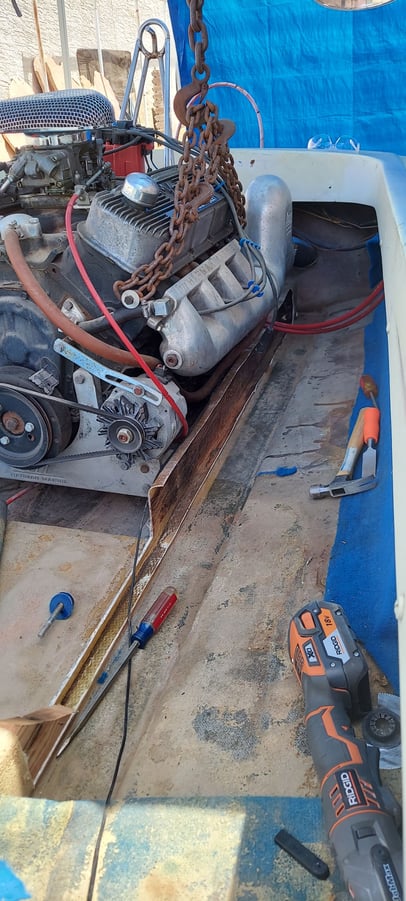

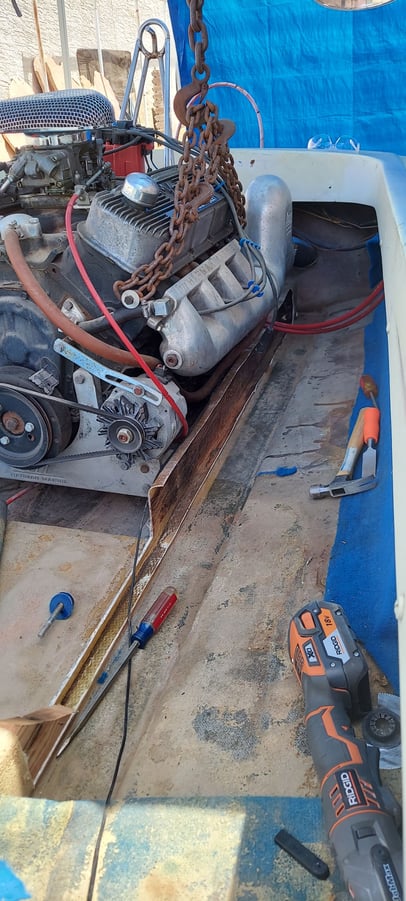

Rear motor mount to stringer. Saw this and knew I had a project on my hands. Good thing I got a screaming deal on the boat

Got it on the side of my house 3" of room on each side. My last boat was too wide to clear the natural gas feed to the house.

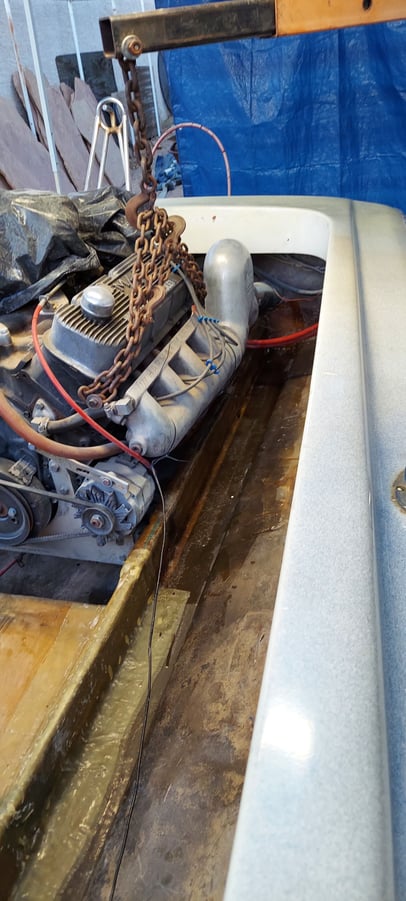

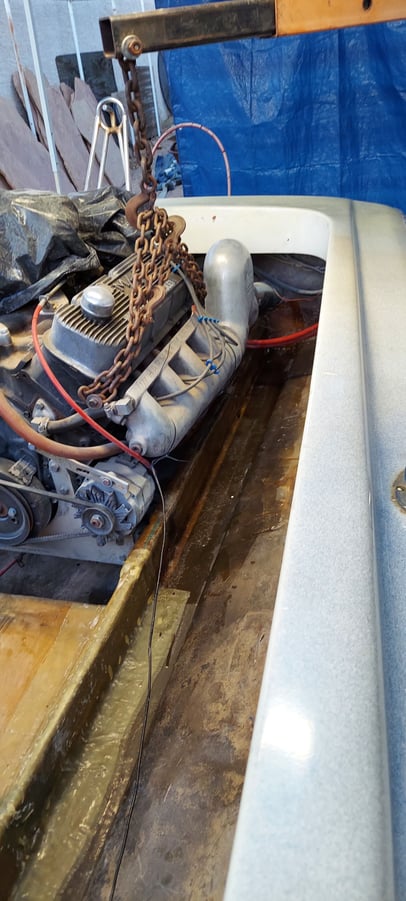

lifted the motor and cut open the stringer. about what I expected.

Started pulling back till I got wood that wasn't powder

Cherry picker holding the motor at the right height

pressure treated board cut and fitted into place

The stuff that soaks up resin....

105F by about 10am, making powder and preping for the 1st shot of glass.

Fiber glass and Kevlar fitting. Kevlar is a b|tch to cut

1st layer bonded in

attempting to take a selfie in my neighbors HTM as we are doing almost 90MPH

~90MPH in a HTM

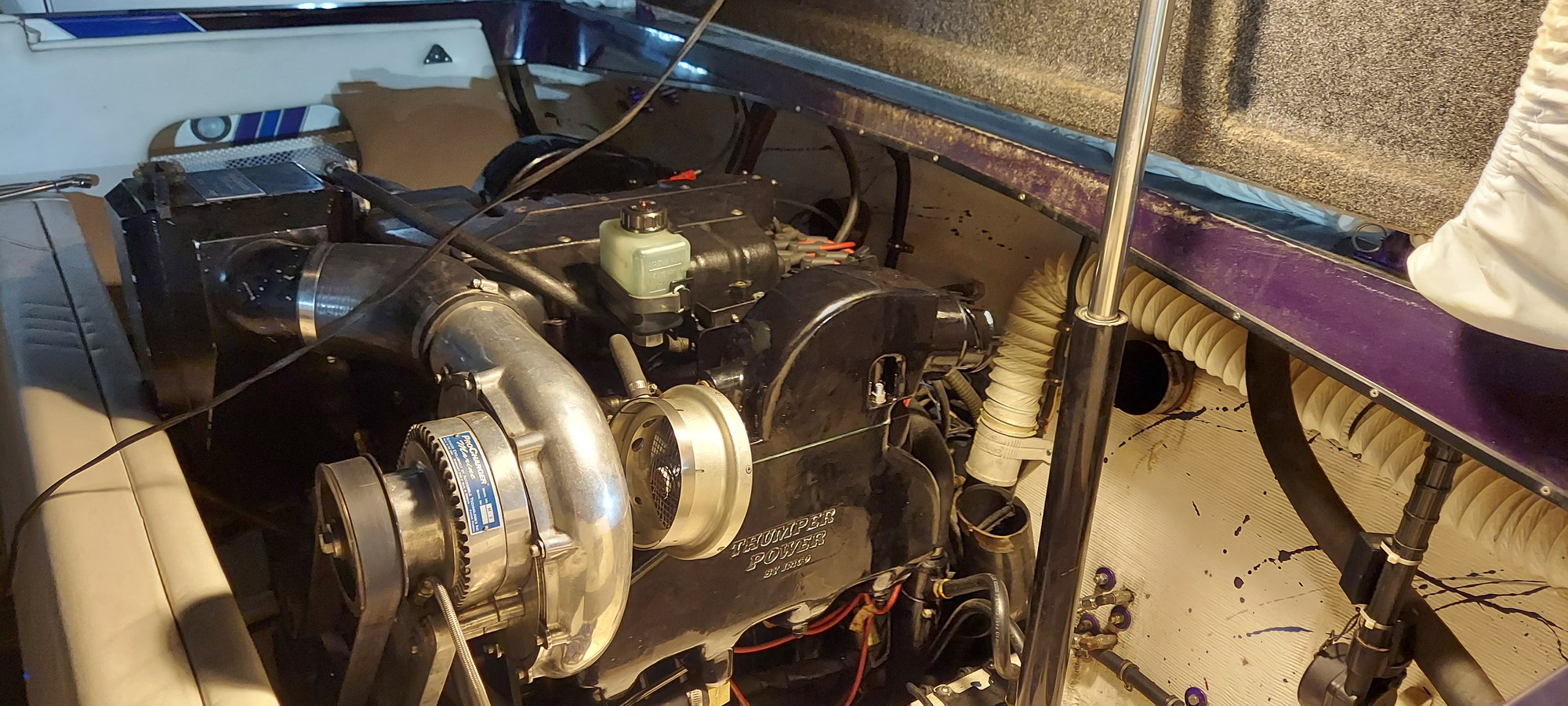

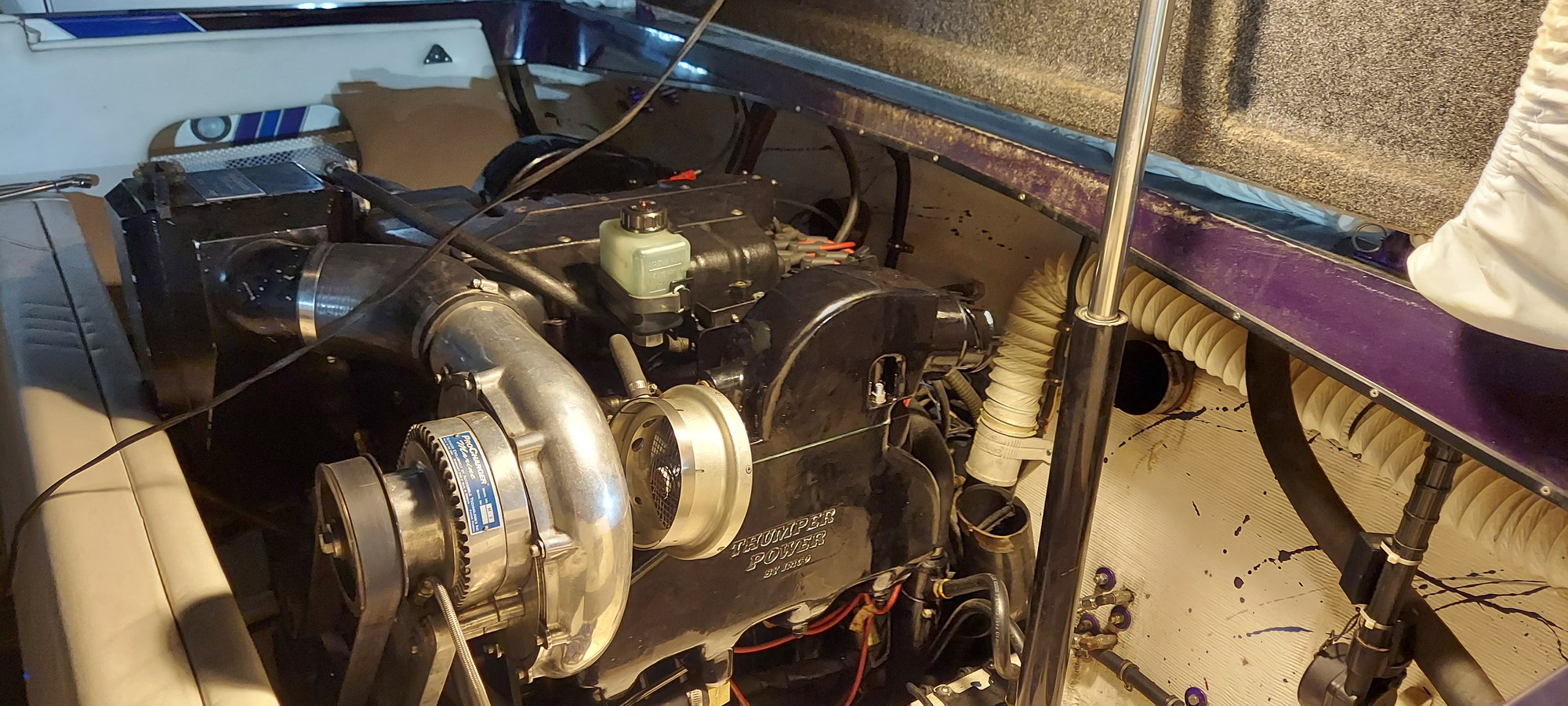

helping work on my buddies HTM with a blow 502 BBC

The following day my neighbor and I flushed both fuel tanks. Orange sludge came out, about 12 gallons worth on a boat "that was stored empty", kept flushing till the gas coming out was as clear and clean as the gas going in, the old gas and the new gas would not mix.... nothing like tossing 20 gallons of good gas....

New filter in, I think I will replace the lines from the fuel tank to the selector, seems like cheap insurance at $1.50/ft... last think I want to do is plug up my system while out on the lake to save $15. Thinking I should replace the coolant feed lines.... they are looking rather old.

I will need to rebuild the holly that is on there, once I figure out what I have. Good news though, little bit of fresh 91 in a can pumped into the car and that 454 comes to life, carb leaks out of every seal but sounds healthy.

While trying to get her started there was a minor issue, either the former owners miss wired her or I have a short. The tach output from the MSD street fire is shorted to GND, once it was removed from the system, it all worked. One more thing to look into.

Bringing her home on day 1

"how you leave the battery" this will change

Rear motor mount to stringer. Saw this and knew I had a project on my hands. Good thing I got a screaming deal on the boat

Got it on the side of my house 3" of room on each side. My last boat was too wide to clear the natural gas feed to the house.

lifted the motor and cut open the stringer. about what I expected.

Started pulling back till I got wood that wasn't powder

Cherry picker holding the motor at the right height

pressure treated board cut and fitted into place

The stuff that soaks up resin....

105F by about 10am, making powder and preping for the 1st shot of glass.

Fiber glass and Kevlar fitting. Kevlar is a b|tch to cut

1st layer bonded in

attempting to take a selfie in my neighbors HTM as we are doing almost 90MPH

~90MPH in a HTM

helping work on my buddies HTM with a blow 502 BBC

Last edited by KeatonAZ; 05-11-2021 at 01:03 AM.

#2

Registered

Thread Starter

more glassing. have to let it cure so I can sand it for layer 2 of glass/kevlar.

This AZ heat of 100F has that resin kicking off fast, I get maybe 10-15 minutes to wet everything and get air bubbles out for it kicks off. getting some air bubble and not sure what to do about it.

more glass

was not happy with a battery just floating around. build up a shelf. will seal up the shelf, glass it, and tab it into the boat. then get a box and mount it... after some clean up and prep work

battery box platform. needs to be glassed and sealed.

This AZ heat of 100F has that resin kicking off fast, I get maybe 10-15 minutes to wet everything and get air bubbles out for it kicks off. getting some air bubble and not sure what to do about it.

more glass

was not happy with a battery just floating around. build up a shelf. will seal up the shelf, glass it, and tab it into the boat. then get a box and mount it... after some clean up and prep work

battery box platform. needs to be glassed and sealed.