Transom Replacement Coosa or Wood

#11

*

On the Coosa page listing advantages it gives a comprehensive list but it doesn't say anything about compression tension , as in through bolting stuff through the transom. That would be my only concern as it otherwise sounds like a very good composite boat building material .

All of the reputable builders I've seen who use coring in their hulls , balsa or foam , (but not transoms) typically go to single skin/solid glass around all through hulls. They obviously have a reason for that. Would the same apply for Coosa ?

Edited to add ..

Thanks to Amiable's post below I can now see what I couldn't find previously.

My guess is that for transoms they'd advise on the 'heavier' version . I like the sound of this stuff but in the past I've only used regular foam products and they worked spectacularly for what I wanted , but that didn't include the transom .

And S/L makes a very valid point about the cost effectiveness when used for transoms .

All of the reputable builders I've seen who use coring in their hulls , balsa or foam , (but not transoms) typically go to single skin/solid glass around all through hulls. They obviously have a reason for that. Would the same apply for Coosa ?

Edited to add ..

Thanks to Amiable's post below I can now see what I couldn't find previously.

My guess is that for transoms they'd advise on the 'heavier' version . I like the sound of this stuff but in the past I've only used regular foam products and they worked spectacularly for what I wanted , but that didn't include the transom .

And S/L makes a very valid point about the cost effectiveness when used for transoms .

Last edited by madbouyz; 11-10-2021 at 07:28 AM.

#12

Registered

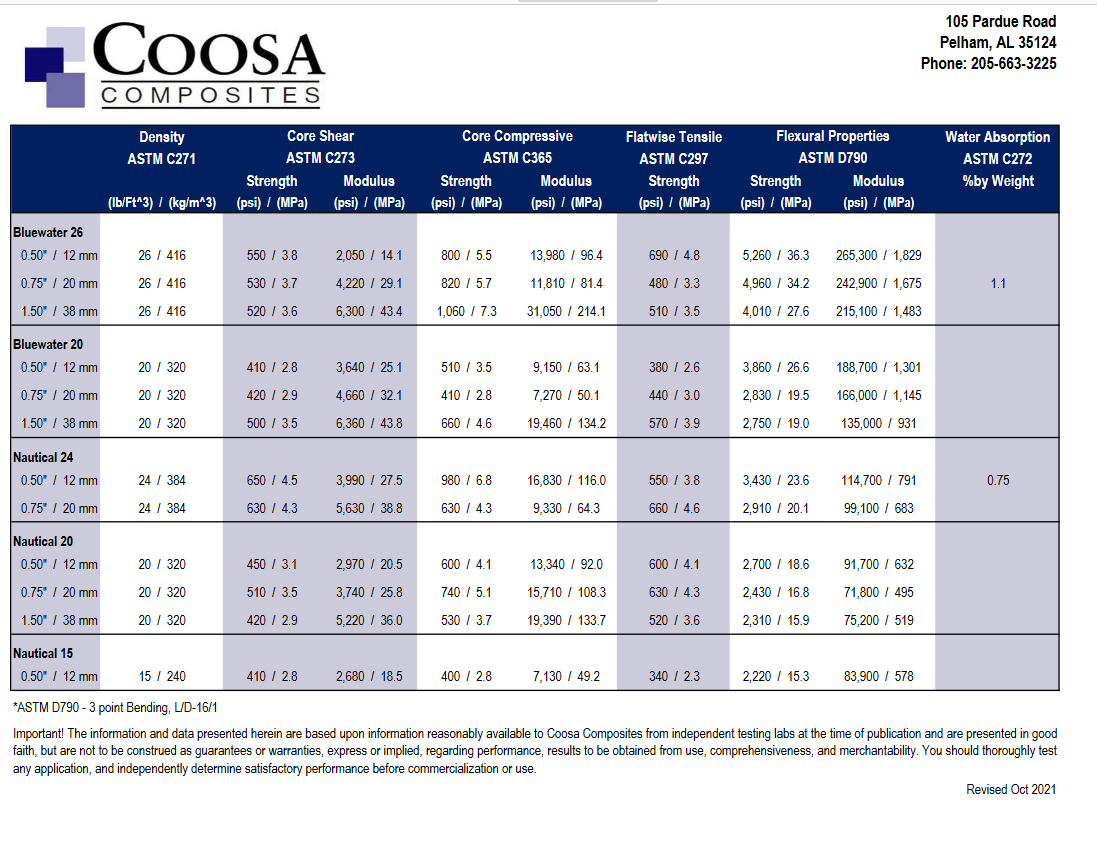

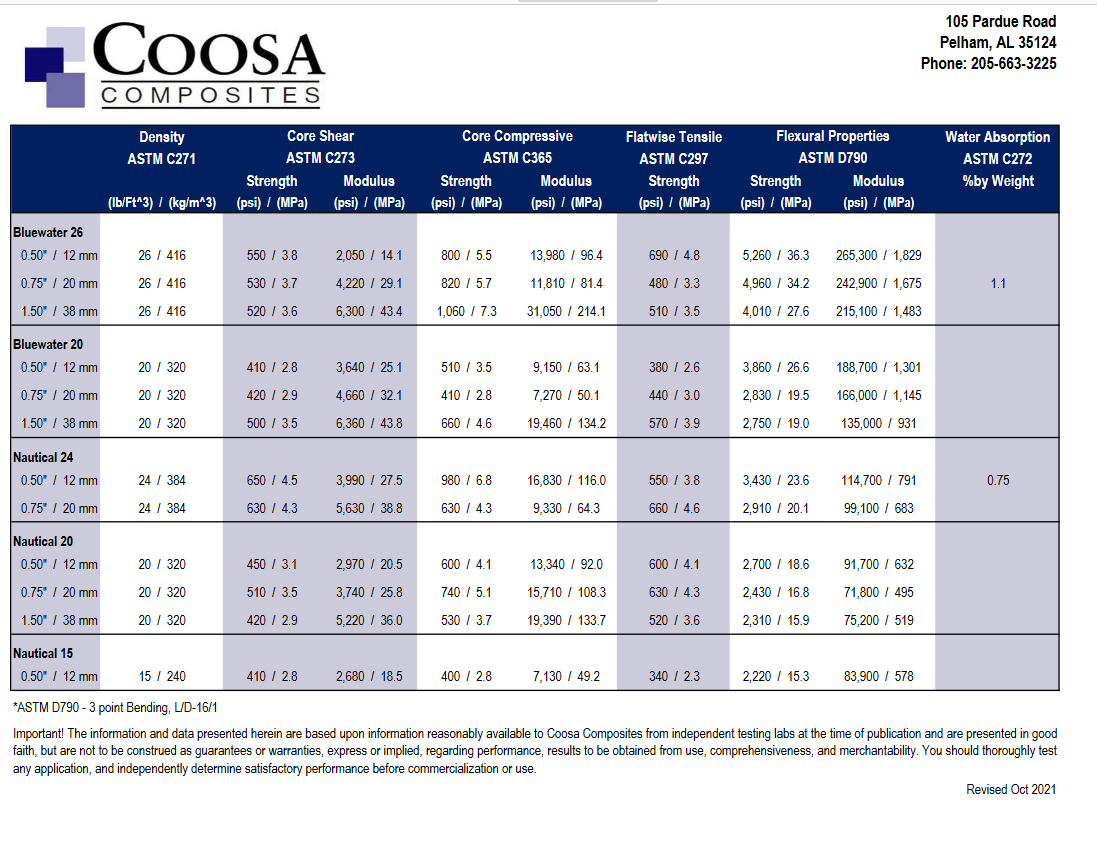

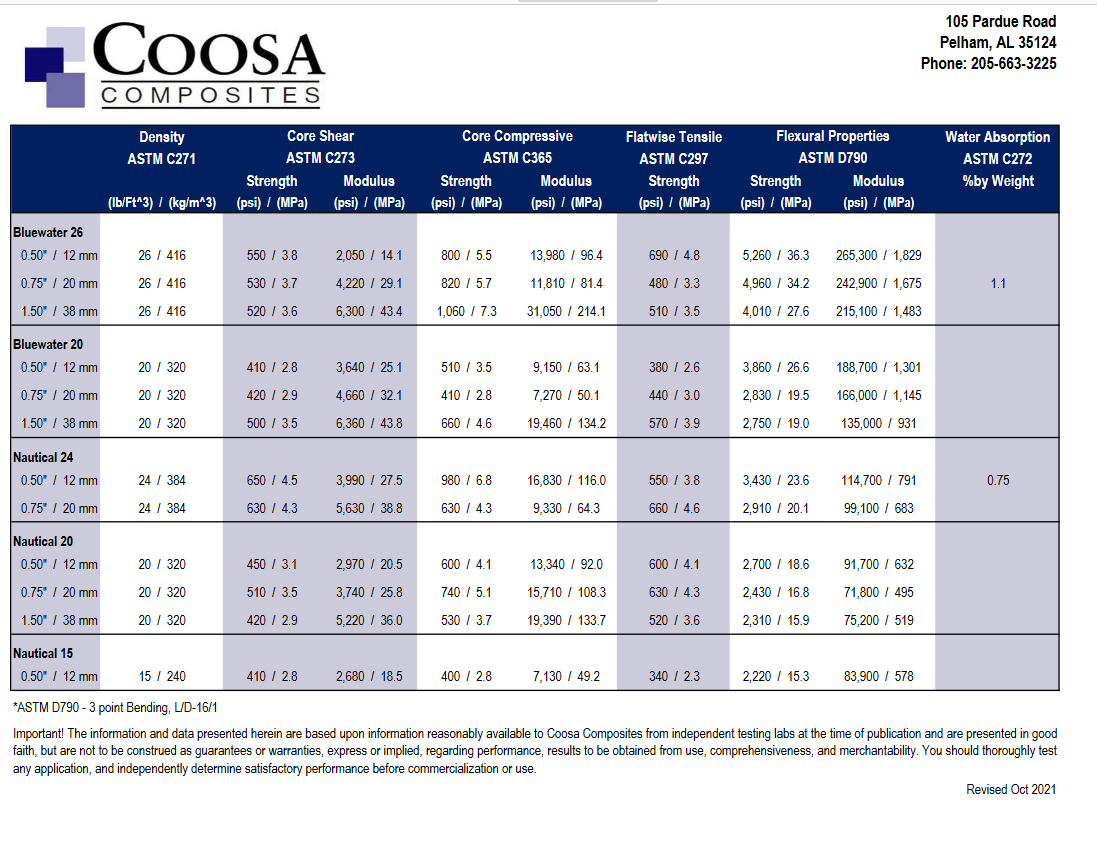

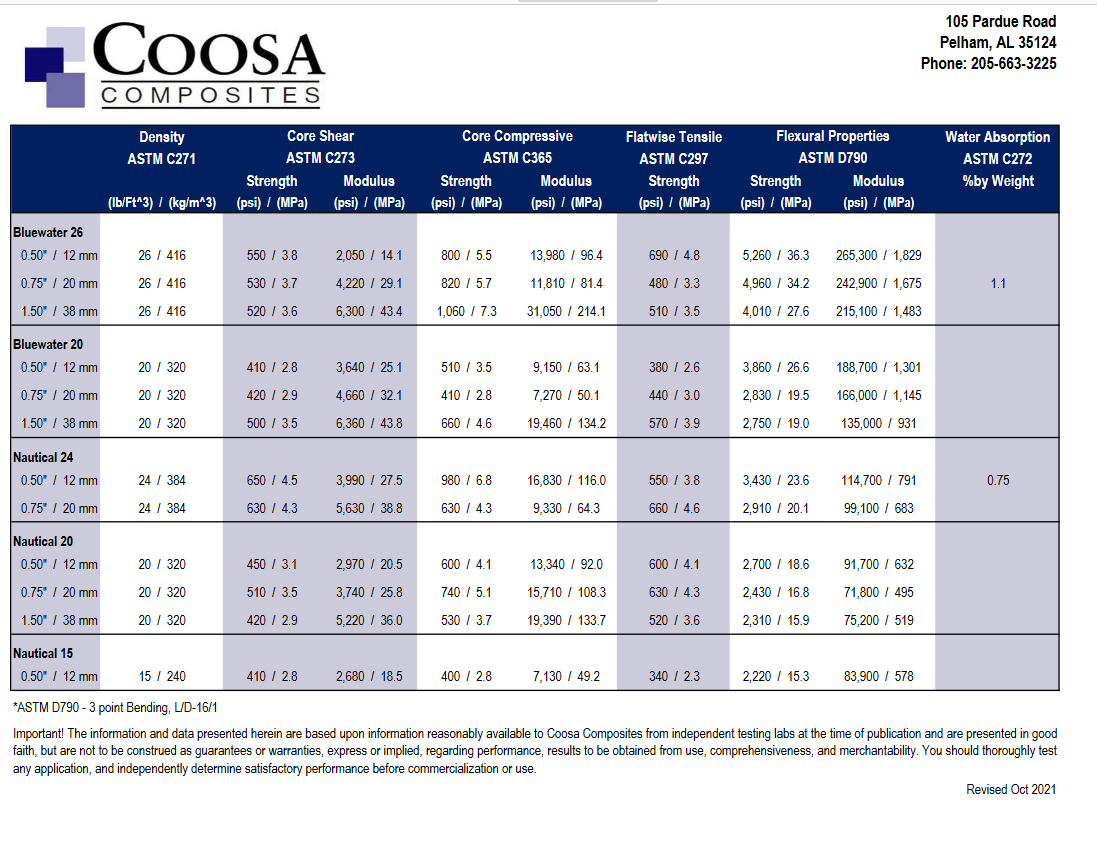

ALL the information, Tech Data, about Coosa is on their web site. Posted is their test data. It's impressive. The only problem with Coosa is its price. It's 3 to 4 times that of plywood. So one has to ask themselves is the boat worth it. That said, give them a call. Ask questions....

#13

Registered

ALL the information, Tech Data, about Coosa is on their web site. Posted is their test data. It's impressive. The only problem with Coosa is its price. It's 3 to 4 times that of plywood. So one has to ask themselves is the boat worth it. That said, give them a call. Ask questions....

Last edited by speicher lane; 11-09-2021 at 02:18 PM.

#15

*

Is he talking out the transom slug itself or where the slug meets the hull ? Is the Coosa like a steel plate compared to a plywood cored transom ?

Not being snarky , just genuinely curious.

#16

Registered

Thread Starter

After ample research, I've pretty much decided to go with good old fashioned CCA treated Marine Plywood. It can be had with a lifetime warranty against decay and rot. Yes it can get wet, but it does not rot. Delamination is the main concern if water gets into the transom. Concerns about Coosa were the compression strength in this application. My 2000 36 Outlaw was not designed to have a composite transom. Had that material been available and had the hull be designed with the materials properties in mind I would not be as concerned about using it. I've been able to find information on many transom replacements with Coosa, but none on large performance boats. Lets face it, there is alot more force on the transom on a performance twin engine V hull that weighs 10K pounds than there is on a bass boat, a cruiser, or other hull type. Add to that the extra load from exit and re-entry when running in the rough. My transom has lasted 21 years. It has some delamination and areas of high moisture, but has no cracking or signs of rot. My builder indicated it border line, but its a trailer queen and doesn't sit in the water. I'm only doing the transom as the motors are out for repower, and the drive are out for upgrades/rebuilds so much of that labor is already done.

Cost of Coosa was not an issue. Yes it 3 - 4 times the cost for the material, but the cost isn't in the material, its in the labor. I'm guessing this will be in the $6K to $8K range depending on what we find once the inner skin comes off. Builder is doing replacement from the inside for what thats worth.

Wish I could've found some examples similar to mine, but seems like everyone is still using plywood in these older boats.

Cost of Coosa was not an issue. Yes it 3 - 4 times the cost for the material, but the cost isn't in the material, its in the labor. I'm guessing this will be in the $6K to $8K range depending on what we find once the inner skin comes off. Builder is doing replacement from the inside for what thats worth.

Wish I could've found some examples similar to mine, but seems like everyone is still using plywood in these older boats.

The following users liked this post:

ICDEDPPL (11-11-2021)

#17

Registered

After ample research, I've pretty much decided to go with good old fashioned CCA treated Marine Plywood. I'm guessing this will be in the $6K to $8K range depending on what we find once the inner skin comes off. Builder is doing replacement from the inside for what thats worth.

Wish I could've found some examples similar to mine, but seems like everyone is still using plywood in these older boats.

Wish I could've found some examples similar to mine, but seems like everyone is still using plywood in these older boats.

As you probably know the majority of the cost is in the labor and from my experience it seems you're undershooting the cost a bunch. Mine was reconstructed from the inside out, outer glass and gel coat saved and a 4' long engine room only stringer replaced. At around $100/hr. my total bill was $15k. This was in April 2021 when only plywood cost was an issue at the time, now EVERYTHING is up. The boat was with the structural repair shop for 6 weeks and only one other boat was in the shop at the time. FWIW everything I've read on OSO says to plan for $15k for a 24' long plus 7.5'-9' beam transom replacement.

Last edited by Tractionless; 11-19-2021 at 09:29 PM.

#18

Registered

The materials cost difference will be negligible compared to the cost of labor. It really comes down to how long do you intend to keep the boat.

One thing about wood. It WILL get wet (it’s a boat right?) and when it does it WILL rot/delaminate.

Also what is sold as “marine” ply now is now what it once was. The surface plies might be clear Douglass fir which is fairly rot resistant, but the hidden inner plies are often inferior species of timber. Add in the inevitable voids (rot pockets) and the stage is set for degradation.

I’ve built several wooden boats. REAL marine grade plywood with a BS 1088 rating from Lloyds is typically made from Meranti or Sapele. It’s expensive, maybe even more than coosa.

Good friend of mine that is building a 46’ power cruiser was going to use Douglas fir marine ply but was so unhappy with the quality of it he went with MDO instead. Medium Density Overlay (NOT MDF) is more commonly called signboard. All plies are doug fir, almost no voids and it laminated with a truly waterproof adhesive. He’s glassing over it. Price per sheet was about the same as the aforementioned Doug fir marine ply.

One thing about wood. It WILL get wet (it’s a boat right?) and when it does it WILL rot/delaminate.

Also what is sold as “marine” ply now is now what it once was. The surface plies might be clear Douglass fir which is fairly rot resistant, but the hidden inner plies are often inferior species of timber. Add in the inevitable voids (rot pockets) and the stage is set for degradation.

I’ve built several wooden boats. REAL marine grade plywood with a BS 1088 rating from Lloyds is typically made from Meranti or Sapele. It’s expensive, maybe even more than coosa.

Good friend of mine that is building a 46’ power cruiser was going to use Douglas fir marine ply but was so unhappy with the quality of it he went with MDO instead. Medium Density Overlay (NOT MDF) is more commonly called signboard. All plies are doug fir, almost no voids and it laminated with a truly waterproof adhesive. He’s glassing over it. Price per sheet was about the same as the aforementioned Doug fir marine ply.

The following users liked this post:

IGetWet (11-24-2021)

#19

Registered

So something like this probably isn’t the quality it used to be?

https://www.menards.com/main/buildin...5626102278.htm

https://www.menards.com/main/buildin...5626102278.htm