Best set up for block drains

#31

Registered

hmmm those look great

i actually used a large home depot plumbing ball shut off

mounted it directly on block , but it is STILL really hard to reach

think thinking of trying to get hose from block, come to front on motor so it would be easier a access

i actually used a large home depot plumbing ball shut off

mounted it directly on block , but it is STILL really hard to reach

think thinking of trying to get hose from block, come to front on motor so it would be easier a access

#32

Registered

I mentioned before a couple of times however removing plug and installing 1/4" pipe to 6 AN push loc and run hose over top of enge and secure somewhere convenient with a coupler. Makes iit extremely easy to drain once installed. If you do get some blockage just put a little air to the hose. Nice if you wanna flush your blocks from time to time also. About 25.00.

this sounds like the plan!!!!!!!!

#33

Registered

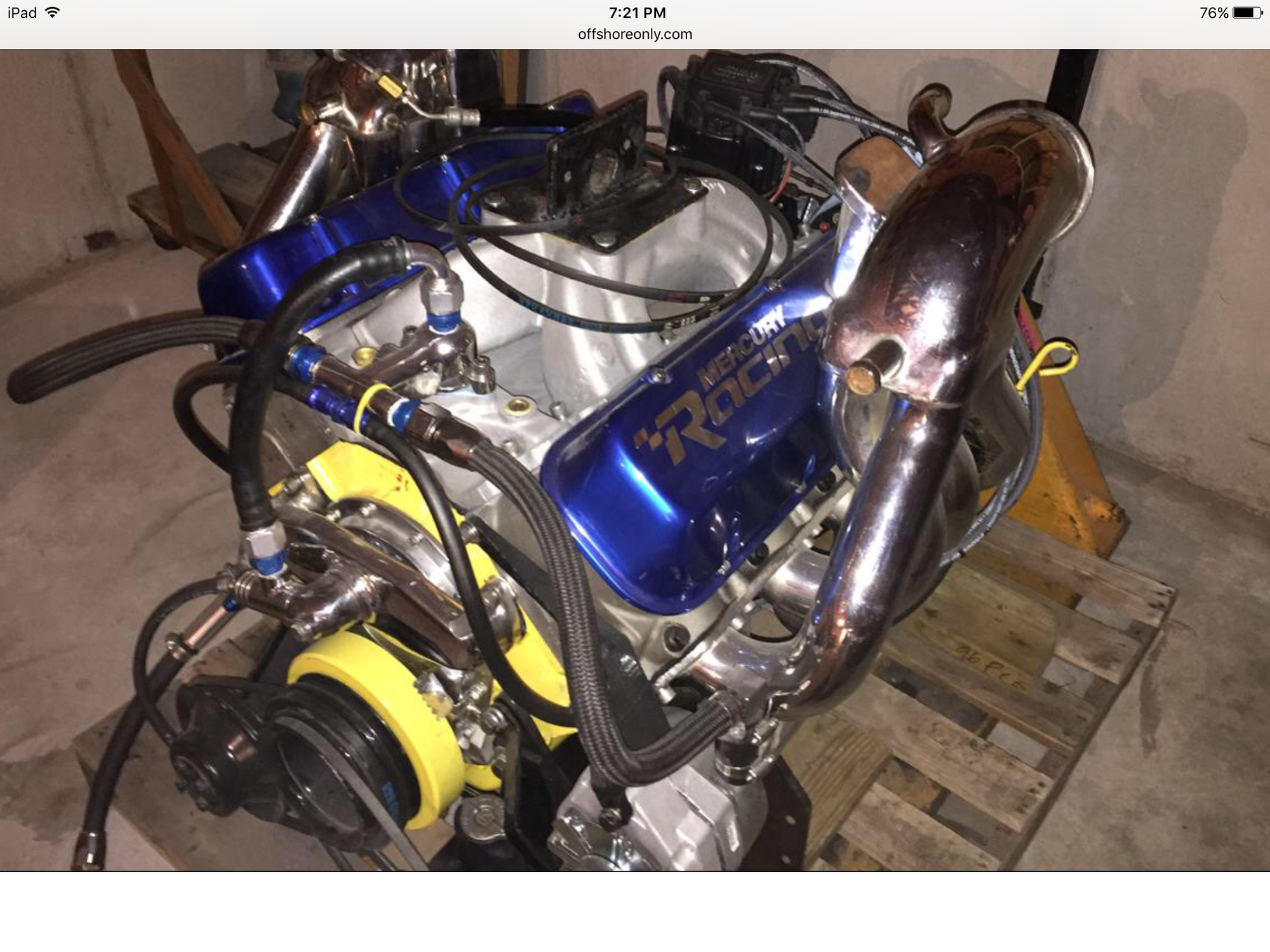

Here's what I did. I installed a AN style fitting into the block and then attached about a 2 ft. length of hose to it. The other end of the hose is secured where I can easily reach it and has an AN style fitting with a cap on it. My thoughts are that I now have the ability to suck water out of the block or push antifreeze into the block if I want. I can also hook up an air compressor and blow air through the block. With this setup you don't have to reach any valves nor are there any valves to rust, break or stick. It's less likely to clog because the orifice is bigger and if it does clog I can clear it with air although a wire will likely still go down the hose as well. I have no idea if it will work as I haven't tried it, but it is installed and ready to go. Here's the oil drain and block drain next to each other at the top of the engine.

this looks great. I really should’ve done something like this when the motors were out. Would save me a lot of time and money in the long run.

#34

Charter Member#568

#36

Banned

iTrader: (9)

here is what we do on the wakeboard engine sides - the factory OEM Indmar does the same. It screws together in the middle and the 2 ends connect to the engine block side drains. You unscrew at the mid connector and that drains both sides of the block at the same time.. Very simple and well proven design.. If you every done one of these you prob would really like it. And the price to do it is very cheap..

#38

Registered

iTrader: (7)

You'll love the symplicity of it. just avoid any 90 deg fittings on or near the block when adapting to hose. Applications obviously vary from boat to boat and engine to engine etc. Straight is ideal.