Allowable vertical play in B1

#11

Registered

learned that the hard way. had to buy 4 new pins. heat definately helped loosen them up. had to helicoil both on one of my drives when installing new pins.

#12

Picked up a heli-coil kit today. I just hope that the opened up hole still has enough material for the STI tap to work. If not, I have a plan to make a solid bushing on the lathe.

Thread an OD of whatever pitch I have tap to match, then thread the ID 5/8-18. If I go this route I'll do both sides.

One question- what are you guys using for heat? I'd rather not cook the finish off my gimbal ring to remove the other hinge pin.

Apparently the red Loctite starts to break down at 360*F, per Loctite. That being the case, I think I'll try the heat gun.

Thread an OD of whatever pitch I have tap to match, then thread the ID 5/8-18. If I go this route I'll do both sides.

One question- what are you guys using for heat? I'd rather not cook the finish off my gimbal ring to remove the other hinge pin.

Apparently the red Loctite starts to break down at 360*F, per Loctite. That being the case, I think I'll try the heat gun.

Last edited by Cole2534; 03-13-2013 at 07:02 PM. Reason: More info

#15

Well I got it all apart and did a halfass job of documenting what I did-

This hole is a little bigger than stock-

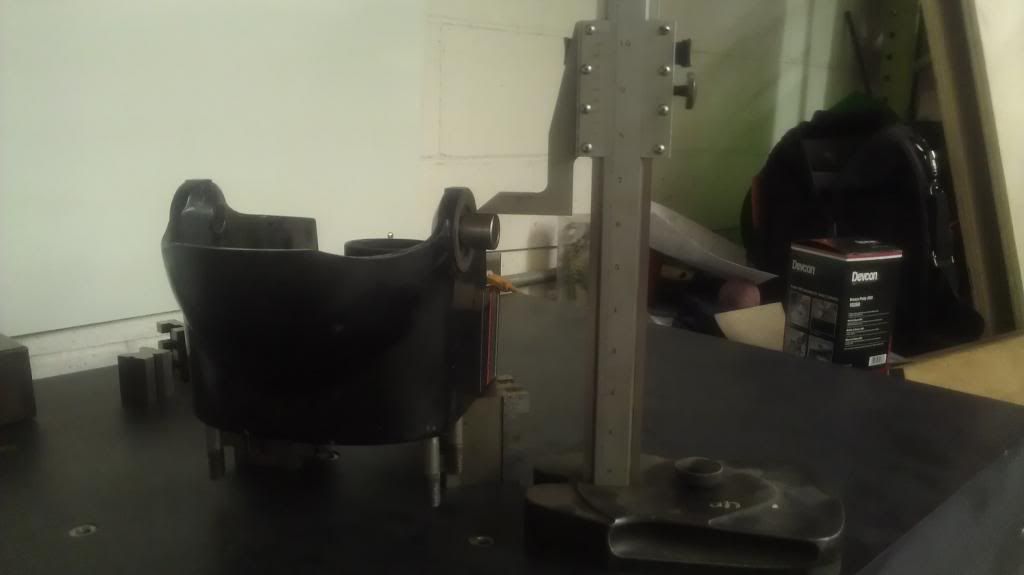

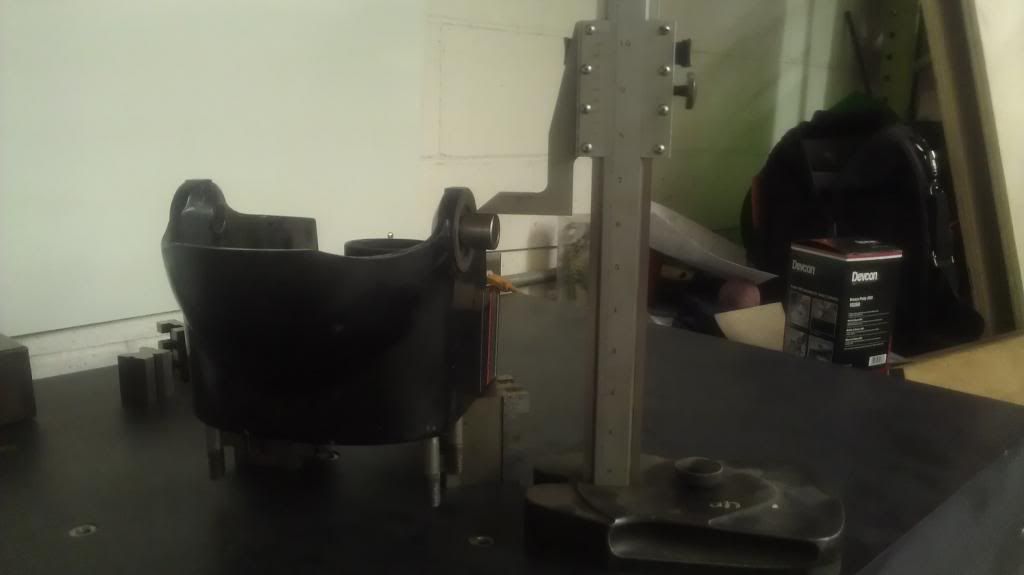

Luckily, the other hole was good. So we set the bellhousing on blocks on the surface plate to get a measurement.

Going back to a round hole, it finally cleared up around .968", guess that explains my slop.

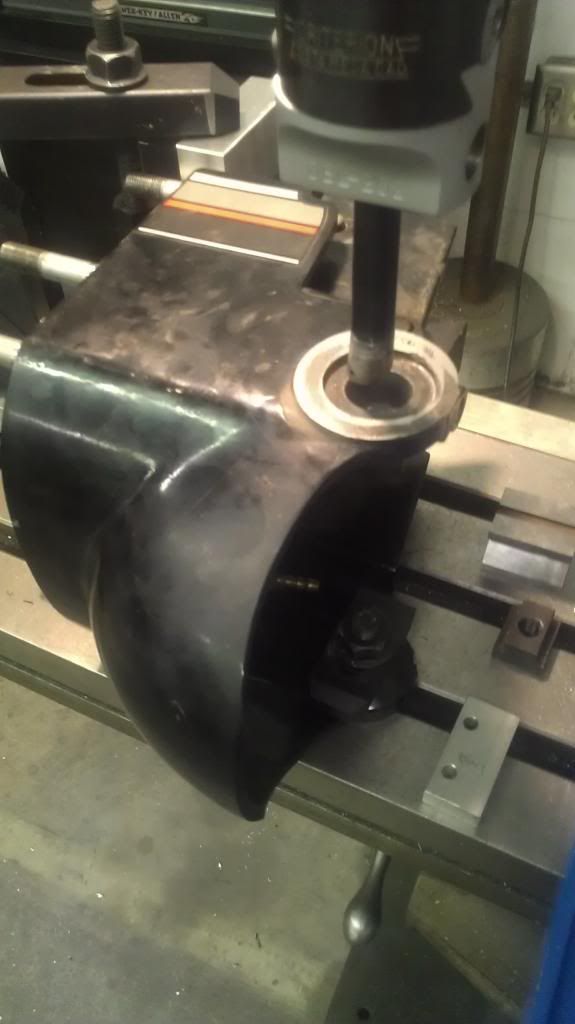

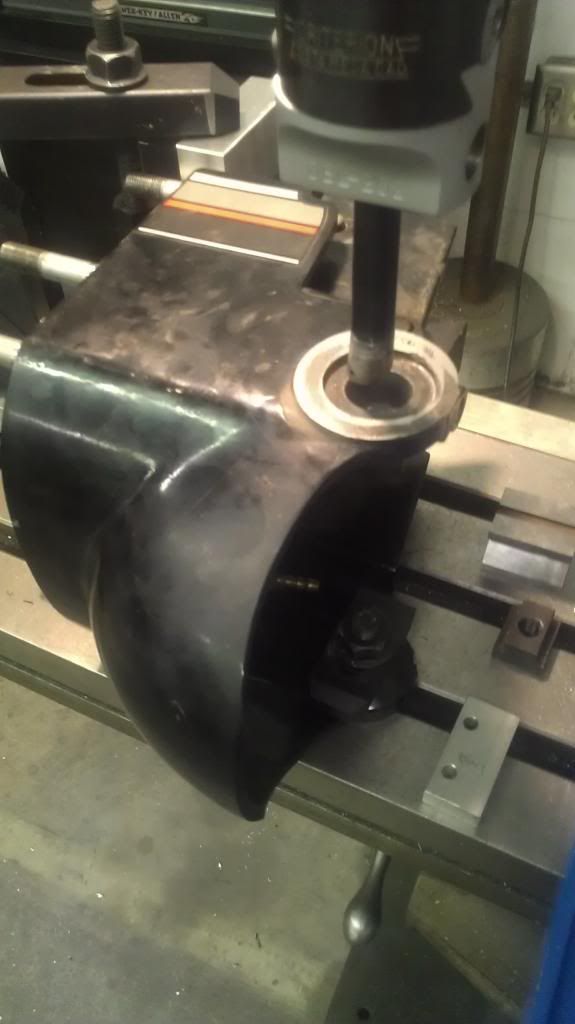

I got in the rhythm and forgot to take a pic of the lathe work, but as you can see the hole is smaller.

From there I installed a Heli-coil and went back together with it.

Aside- the socket I cut for gripping the shift cable nut.

However, it turns out that pliers and a 1/4" impact work even better.

The money I spent on that mill and tooling doesn't seem so bad after saving a bellhousing...

-Cole

This hole is a little bigger than stock-

Luckily, the other hole was good. So we set the bellhousing on blocks on the surface plate to get a measurement.

Going back to a round hole, it finally cleared up around .968", guess that explains my slop.

I got in the rhythm and forgot to take a pic of the lathe work, but as you can see the hole is smaller.

From there I installed a Heli-coil and went back together with it.

Aside- the socket I cut for gripping the shift cable nut.

However, it turns out that pliers and a 1/4" impact work even better.

The money I spent on that mill and tooling doesn't seem so bad after saving a bellhousing...

-Cole