350 EFI TBI Mods, cam, heads, intake, tune, 383?

#41

Registered

Thread Starter

The boat runs great!

Till it hits around 5000 RPM, then the fuel injectors max out.

I changed the base timing to 8 degrees. This made it a little harder to start. It was cranking kind of hard, like an old carb motor with the timing set too high. I may have to change this in the tune, maybe back it off to 5 degrees or so and reset the distributor. Then add the timing back in to the main spark table.

With the stock BPW table I was running around 14.1 AFR with just an easy cruise at about 3000 RPM. I started bumping the BPW table up until I hit 12.5 at 3000 RPM then worked my way up in 500 RPM increments and made fuel adjustments as needed. I am running around 12.5 AFR across the board until the boat hits 5000 RPM and the AFR climbs to the mid 13's and the wide band starts to fluctuate. I also start picking up some spark knock. I know I am not in fuel cut off, becasue I have that set to 5500 RPM, and its not setting the fuel RPM cut off flag in the scanner. The good news is, I am not getting any knock under load at all until it starts to lean out up top.

So, my two main issues are:

https://www.youtube.com/watch?v=GC6j...ature=youtu.be

Till it hits around 5000 RPM, then the fuel injectors max out.

I changed the base timing to 8 degrees. This made it a little harder to start. It was cranking kind of hard, like an old carb motor with the timing set too high. I may have to change this in the tune, maybe back it off to 5 degrees or so and reset the distributor. Then add the timing back in to the main spark table.

With the stock BPW table I was running around 14.1 AFR with just an easy cruise at about 3000 RPM. I started bumping the BPW table up until I hit 12.5 at 3000 RPM then worked my way up in 500 RPM increments and made fuel adjustments as needed. I am running around 12.5 AFR across the board until the boat hits 5000 RPM and the AFR climbs to the mid 13's and the wide band starts to fluctuate. I also start picking up some spark knock. I know I am not in fuel cut off, becasue I have that set to 5500 RPM, and its not setting the fuel RPM cut off flag in the scanner. The good news is, I am not getting any knock under load at all until it starts to lean out up top.

So, my two main issues are:

- Hard starting with 8 degrees initial timing. Which the compression in this motor should be up around 10-10.5:1, being that I put flat top piston in it. So I may need to lower that.

- Not enough fuel up top. I am running the stock injectors, my junkyard 60 pound injectors were junk, wouldn't even pulse. Since the injectors on the boat are 4.3 injectors, ran at a higher fuel pressure, maybe a good set on 60 pound injectors (from a 350) would do the trick. Or, I may have to do some major fuel system upgrades.

https://www.youtube.com/watch?v=GC6j...ature=youtu.be

Last edited by Paxtonspeed; 07-02-2018 at 08:55 AM.

#42

Registered

iTrader: (1)

Surprised the 4.3L injectors let you get that far.

#43

Registered

Thread Starter

Apparently, that's how GM did it. On the late 454 truck, and in the boats with the big block TBI, they used 4.3 injectors. The main difference being, the 4.3 had 12-13 pounds fuel pressure. The big block, and my boat have about 30 pounds of fuel pressure, making the small injector flow more fuel.

The part number on my injector is 5235203, which comes up as a 4.3 injector

Copied from gearhead EFi forum

TBI Injectors

xxxxxxx - color / color - 33pph - 2.8l and 3.1l

xxxxxxx - color / color - 45pph - 4.3l engine NOTE: Some came with 2 differant size injectors?

5235279 - White / Green - 54pph - 5.0L / 305 Cars/Trucks

5235206 - Orange / Black - 61pph - 5.7L / 350 Cars/Trucks

17084327 - Yellow / Brown - 65pph - 5.7L / 350 Police Package

17084304 - Black / Blue - 74pph - 7.4L / 454 - 91-93

5235231 - Red / Blue - 80pph - 7.4L / 454 - 88-90

17104288 - Pink / Purple - 46pph @13psi - 7.4L / 454 - 94-95 *NOTE: Came with 30 PSI regulator used @ 26-32psi for 67-72pph

These flow rates are a safe bet average @ 12-13psi, be aware that actual flow can vary by greater than 10% throughout production.

http://www.gearhead-efi.com/Fuel-Inj...d-part-numbers

The part number on my injector is 5235203, which comes up as a 4.3 injector

Copied from gearhead EFi forum

TBI Injectors

xxxxxxx - color / color - 33pph - 2.8l and 3.1l

xxxxxxx - color / color - 45pph - 4.3l engine NOTE: Some came with 2 differant size injectors?

5235279 - White / Green - 54pph - 5.0L / 305 Cars/Trucks

5235206 - Orange / Black - 61pph - 5.7L / 350 Cars/Trucks

17084327 - Yellow / Brown - 65pph - 5.7L / 350 Police Package

17084304 - Black / Blue - 74pph - 7.4L / 454 - 91-93

5235231 - Red / Blue - 80pph - 7.4L / 454 - 88-90

17104288 - Pink / Purple - 46pph @13psi - 7.4L / 454 - 94-95 *NOTE: Came with 30 PSI regulator used @ 26-32psi for 67-72pph

These flow rates are a safe bet average @ 12-13psi, be aware that actual flow can vary by greater than 10% throughout production.

http://www.gearhead-efi.com/Fuel-Inj...d-part-numbers

Last edited by Paxtonspeed; 07-02-2018 at 11:15 AM.

#44

The boat runs great!

Till it hits around 5000 RPM, then the fuel injectors max out.

I changed the base timing to 8 degrees. This made it a little harder to start. It was cranking kind of hard, like an old carb motor with the timing set too high. I may have to change this in the tune, maybe back it off to 5 degrees or so and reset the distributor. Then add the timing back in to the main spark table.

With the stock BPW table I was running around 14.1 AFR with just an easy cruise at about 3000 RPM. I started bumping the BPW table up until I hit 12.5 at 3000 RPM then worked my way up in 500 RPM increments and made fuel adjustments as needed. I am running around 12.5 AFR across the board until the boat hits 5000 RPM and the AFR climbs to the mid 13's and the wide band starts to fluctuate. I also start picking up some spark knock. I know I am not in fuel cut off, becasue I have that set to 5500 RPM, and its not setting the fuel RPM cut off flag in the scanner. The good news is, I am not getting any knock under load at all until it starts to lean out up top.

So, my two main issues are:

https://www.youtube.com/watch?v=GC6j...ature=youtu.be

Till it hits around 5000 RPM, then the fuel injectors max out.

I changed the base timing to 8 degrees. This made it a little harder to start. It was cranking kind of hard, like an old carb motor with the timing set too high. I may have to change this in the tune, maybe back it off to 5 degrees or so and reset the distributor. Then add the timing back in to the main spark table.

With the stock BPW table I was running around 14.1 AFR with just an easy cruise at about 3000 RPM. I started bumping the BPW table up until I hit 12.5 at 3000 RPM then worked my way up in 500 RPM increments and made fuel adjustments as needed. I am running around 12.5 AFR across the board until the boat hits 5000 RPM and the AFR climbs to the mid 13's and the wide band starts to fluctuate. I also start picking up some spark knock. I know I am not in fuel cut off, becasue I have that set to 5500 RPM, and its not setting the fuel RPM cut off flag in the scanner. The good news is, I am not getting any knock under load at all until it starts to lean out up top.

So, my two main issues are:

- Hard starting with 8 degrees initial timing. Which the compression in this motor should be up around 10-10.5:1, being that I put flat top piston in it. So I may need to lower that.

- Not enough fuel up top. I am running the stock injectors, my junkyard 60 pound injectors were junk, wouldn't even pulse. Since the injectors on the boat are 4.3 injectors, ran at a higher fuel pressure, maybe a good set on 60 pound injectors (from a 350) would do the trick. Or, I may have to do some major fuel system upgrades.

https://www.youtube.com/watch?v=GC6j...ature=youtu.be

What is your spark advance at 5000 rpm (in other words what is your 3200 rpm / 100kPa spark setting)?

Are you getting 98-100 kPa or something less at WOT?

Like SB said I'm surprised you got as far as you did with 4.3 injectors. There are some higher flow TBI injectors you may need to install, I just can't remember the source right now. I'm not a fan of bumping fuel pressure to cover for lack of injector, but your hands are somewhat tied at this point.

#45

Registered

Thread Starter

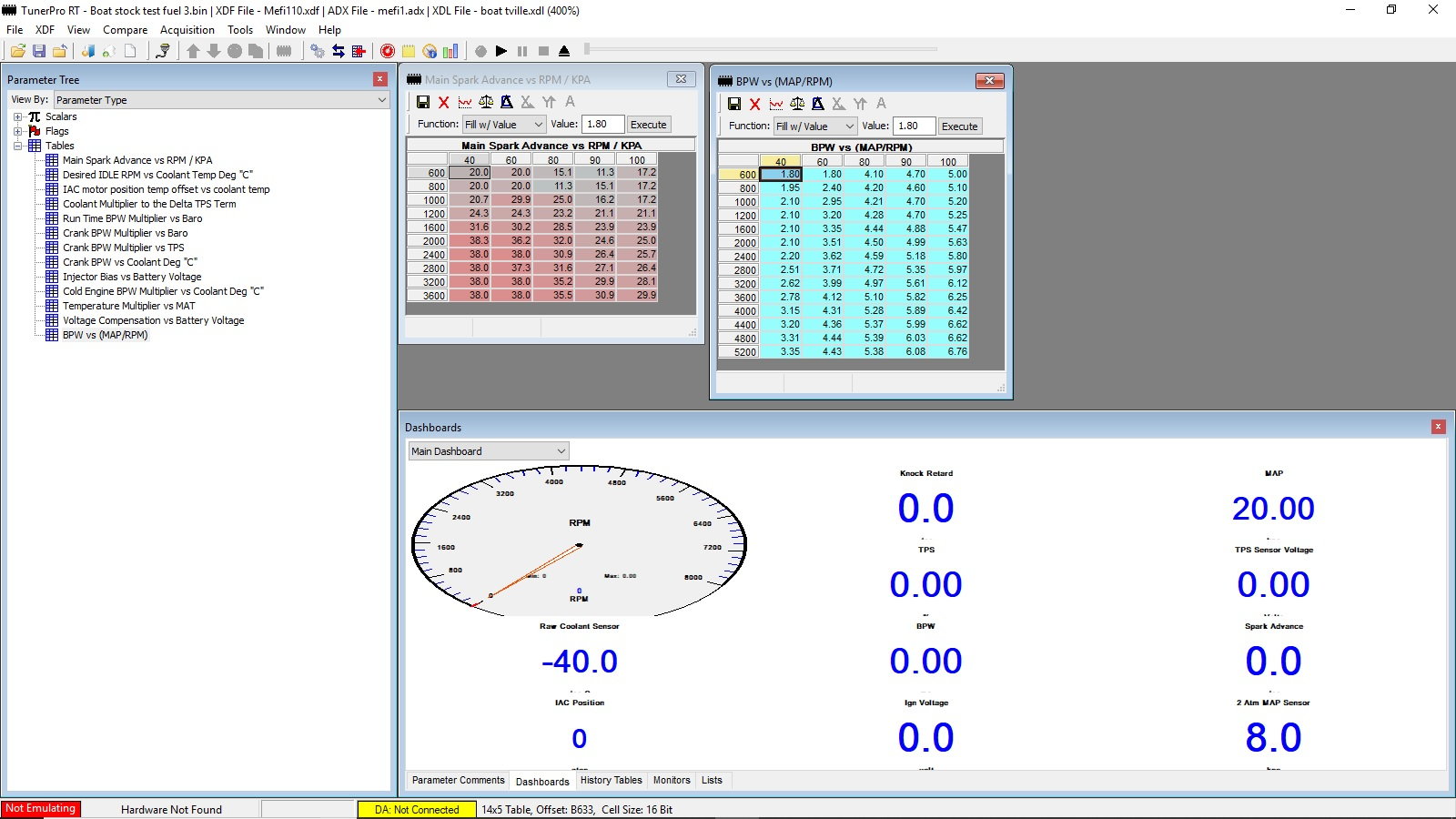

What is your table spark advance for 600/800 rpm at 40 and 60 kPa?

What is your spark advance at 5000 rpm (in other words what is your 3200 rpm / 100kPa spark setting)?

Are you getting 98-100 kPa or something less at WOT?

Like SB said I'm surprised you got as far as you did with 4.3 injectors. There are some higher flow TBI injectors you may need to install, I just can't remember the source right now. I'm not a fan of bumping fuel pressure to cover for lack of injector, but your hands are somewhat tied at this point.

What is your spark advance at 5000 rpm (in other words what is your 3200 rpm / 100kPa spark setting)?

Are you getting 98-100 kPa or something less at WOT?

Like SB said I'm surprised you got as far as you did with 4.3 injectors. There are some higher flow TBI injectors you may need to install, I just can't remember the source right now. I'm not a fan of bumping fuel pressure to cover for lack of injector, but your hands are somewhat tied at this point.

I am at work, so I will have to go back and look for everything you asked for. I do have a short recorded log that shows whats going on when it leans out at 5000 RPM, everything but AFR. It seems to happen when the BPW hits 6.

Like I said the spark table is stock, other than the idle area. I can send you the log, and take a few screen shots of the tune.

I am not getting anywhere near WOT.....

As far as raising fuel pressure, that's how GM did it on the 4.3 injectors. I am not looking to raise it anymore, I am going to source some new injectors.

#46

Registered

Thread Starter

Just realized the main spark table only goes to 3600 RPM, at 100 KPA timing is 29.9 degrees.

In my log, the scanner is showing 37-38 degrees of timing, max MAP reading is about 80 KPA, about 50% throttle.

All this while running on the hairy edge of it going lean.

I guess its adding in the initial timing to the main spark table. Thats a lot of timing! Didn't realize it was that high!

In my log, the scanner is showing 37-38 degrees of timing, max MAP reading is about 80 KPA, about 50% throttle.

All this while running on the hairy edge of it going lean.

I guess its adding in the initial timing to the main spark table. Thats a lot of timing! Didn't realize it was that high!

#48

Drop your idle timing down to 10.1 in the 600 / 40kPa and 600 / 60 kPa cells.

Set timing to around 15 in the 800 / 40 kPa cell.

That table is set up more for a non-Vortec style head, Newer heads don't need, nor like as much advance in the load region.

Besides the two corrections I stated in the 40 kPa column leave the other 40 kPa values alone. The high advance in that region is beneficial during deceleration.

For starters in the 60 and 80 kPa columns from 2000 rpm to 3600 rpm I'd set 32 degrees, leaving all the other cell values alone. See how it runs. If it seems sluggish or lazy coming on plane add a little timing in the 2400 and 2800 rpm rows in the 60 & 80 kPa columns. Of course all this is commensurate with limited or no knock retard kicking in.

Set timing to around 15 in the 800 / 40 kPa cell.

That table is set up more for a non-Vortec style head, Newer heads don't need, nor like as much advance in the load region.

Besides the two corrections I stated in the 40 kPa column leave the other 40 kPa values alone. The high advance in that region is beneficial during deceleration.

For starters in the 60 and 80 kPa columns from 2000 rpm to 3600 rpm I'd set 32 degrees, leaving all the other cell values alone. See how it runs. If it seems sluggish or lazy coming on plane add a little timing in the 2400 and 2800 rpm rows in the 60 & 80 kPa columns. Of course all this is commensurate with limited or no knock retard kicking in.

#50

Registered

Thread Starter

Drop your idle timing down to 10.1 in the 600 / 40kPa and 600 / 60 kPa cells.

Set timing to around 15 in the 800 / 40 kPa cell.

That table is set up more for a non-Vortec style head, Newer heads don't need, nor like as much advance in the load region.

Besides the two corrections I stated in the 40 kPa column leave the other 40 kPa values alone. The high advance in that region is beneficial during deceleration.

For starters in the 60 and 80 kPa columns from 2000 rpm to 3600 rpm I'd set 32 degrees, leaving all the other cell values alone. See how it runs. If it seems sluggish or lazy coming on plane add a little timing in the 2400 and 2800 rpm rows in the 60 & 80 kPa columns. Of course all this is commensurate with limited or no knock retard kicking in.

Set timing to around 15 in the 800 / 40 kPa cell.

That table is set up more for a non-Vortec style head, Newer heads don't need, nor like as much advance in the load region.

Besides the two corrections I stated in the 40 kPa column leave the other 40 kPa values alone. The high advance in that region is beneficial during deceleration.

For starters in the 60 and 80 kPa columns from 2000 rpm to 3600 rpm I'd set 32 degrees, leaving all the other cell values alone. See how it runs. If it seems sluggish or lazy coming on plane add a little timing in the 2400 and 2800 rpm rows in the 60 & 80 kPa columns. Of course all this is commensurate with limited or no knock retard kicking in.

The boat ran great, with no knock at all until it started going lean. I tried to upload my log so you could take a look at it if you want, but the sight would not let me, I even changed it to a text file. If you want to PM me your email I can send it to you. If not that's cool too.

Roger that on the prop. Thanks for all the help!

Last edited by Paxtonspeed; 07-03-2018 at 07:04 AM.