350 EFI TBI Mods, cam, heads, intake, tune, 383?

#61

Registered

Thread Starter

For starters in the 60 and 80 kPa columns from 2000 rpm to 3600 rpm I'd set 32 degrees, leaving all the other cell values alone. See how it runs. If it seems sluggish or lazy coming on plane add a little timing in the 2400 and 2800 rpm rows in the 60 & 80 kPa columns. Of course all this is commensurate with limited or no knock retard kicking in.

I think I have it too low now. The boat seemed more responsive when I had the stock injectors in it, with the stock timing table, and the 8 degrees initial timing. Even though the timing was high, I didn't get any spark knock up until it started leaning out. I went back and looked at my logs to confirm. My original logs seemed like the advance being report was the initial + the main timing table. Since I changed the initial to 5 degrees, my log seems to only be reporting what is in the main spark table. I was getting some spark knock at 5000 RPM, AFR was a little rich at 11.9 but timing should have been around 30 degrees. 5 initial + 25 in the main table.

I did some research on the Fast Burn heads as far as timing, and it looks like they like around 34 - 36 degrees. I am running 93 octane fuel, compression should be around 10.5:1, so I have some more tuning to do.

I may start over, put the initial back to 8, lower the idle timing to 10 in the main table, to eliminate starting issues and re work the rest of the timing table.

Trash, when you talking about 32 degrees, was that including the 8 initial, or 32 plus the 8 initial?

#62

Took the boat out yesterday and had a few problems. I think I am chasing my tail with timing.

I think I have it too low now. The boat seemed more responsive when I had the stock injectors in it, with the stock timing table, and the 8 degrees initial timing. Even though the timing was high, I didn't get any spark knock up until it started leaning out. I went back and looked at my logs to confirm. My original logs seemed like the advance being report was the initial + the main timing table. Since I changed the initial to 5 degrees, my log seems to only be reporting what is in the main spark table. I was getting some spark knock at 5000 RPM, AFR was a little rich at 11.9 but timing should have been around 30 degrees. 5 initial + 25 in the main table.

I did some research on the Fast Burn heads as far as timing, and it looks like they like around 34 - 36 degrees. I am running 93 octane fuel, compression should be around 10.5:1, so I have some more tuning to do.

I may start over, put the initial back to 8, lower the idle timing to 10 in the main table, to eliminate starting issues and re work the rest of the timing table.

Trash, when you talking about 32 degrees, was that including the 8 initial, or 32 plus the 8 initial?

I think I have it too low now. The boat seemed more responsive when I had the stock injectors in it, with the stock timing table, and the 8 degrees initial timing. Even though the timing was high, I didn't get any spark knock up until it started leaning out. I went back and looked at my logs to confirm. My original logs seemed like the advance being report was the initial + the main timing table. Since I changed the initial to 5 degrees, my log seems to only be reporting what is in the main spark table. I was getting some spark knock at 5000 RPM, AFR was a little rich at 11.9 but timing should have been around 30 degrees. 5 initial + 25 in the main table.

I did some research on the Fast Burn heads as far as timing, and it looks like they like around 34 - 36 degrees. I am running 93 octane fuel, compression should be around 10.5:1, so I have some more tuning to do.

I may start over, put the initial back to 8, lower the idle timing to 10 in the main table, to eliminate starting issues and re work the rest of the timing table.

Trash, when you talking about 32 degrees, was that including the 8 initial, or 32 plus the 8 initial?

The timing value you see on Scanner Pro should be nearly equal to the cell value in the ECM. There may be some slight differences as F1 slope modifier and a few other parameters may be temporarily altering the value a bit. But in general the values should match very closely.

I'm running Dart Iron eagles and did some timing experimentation. I ran VP110 race gas so I could 'jack' the timing up to see if anything could be gained. I was up to 38 degrees at WOT but didn't see ANY gain. I did alter the fuel tables for the VP110 as its stoic is different than regular gas. Sweet spot is between 32-34 degrees. If you are tickling the knock sensor just pull about half a degree of timing in that cell and try again.

I would set your base timing and leave it. This will have a global affect on the rest of the table if you keep diddling with it.

Here are 3 examples that will hopefully get you started.

This is a bone stock Merc 350 Mag EFI/MP timing table circa 1995 MEFI 1, non-Vortec head model. Sort of pre Scorpion motor. Keep in mind your version of ScannerPro inverts the tables compared to my version.

This is a Merc Scorpion 377 timing table

This is the load currently on my motor (377 stroker, standard bore)

Look how much more timing the non-Vortec head took in the mid-range as compared to the Vortec Scorpion (middle chart) and my load using Dart heads. I could likely plug a little more timing in this midrange on mine but it's splitting hairs and depending on atmospherics will occasionally tickle the knock sensor.

In addition when looking at knock, observe the knock retard to see how much spark is actually getting taken out. It often only needs to pull maybe a half degree to 2 degrees of timing for a short duration then its back to normal. The times where it pulls 8-9 degrees are the zones that really get my attention. You can control how much spark it takes out, the max it takes out and how fast it feeds it back in. BUT!!! I don't mess with those! Stock works well enough.

Another item to consider is if you have MBT in your spark system (Mean Best Timing). During steady state the ignition will advance until it senses either knock OR rpm reduces which effectively hits peak torque. This is most efficient for cruise. However, this is transparent to the end user IF installed unless you are watching it on ScannerPro. Merc employed this on a few motors, perhaps still to this day but I'm don't constantly follow all the latest systems.

Last edited by Trash; 07-17-2018 at 12:39 PM.

#63

Registered

Thread Starter

To get to your question first, yes the 32 deg includes the 8 initial. Think of it this way. You mechanically set 8 deg BTDC in base timing. Then that same value is loaded into the MEFI unit. Now the computer has a starting point from which to work. It assumes the 8 degrees is accurate and then adds timing to reach the total timing value stated in the Spark/MAP/RPM table.

The timing value you see on Scanner Pro should be nearly equal to the cell value in the ECM. There may be some slight differences as F1 slope modifier and a few other parameters may be temporarily altering the value a bit. But in general the values should match very closely.

I'm running Dart Iron eagles and did some timing experimentation. I ran VP110 race gas so I could 'jack' the timing up to see if anything could be gained. I was up to 38 degrees at WOT but didn't see ANY gain. I did alter the fuel tables for the VP110 as its stoic is different than regular gas. Sweet spot is between 32-34 degrees. If you are tickling the knock sensor just pull about half a degree of timing in that cell and try again.

I would set your base timing and leave it. This will have a global affect on the rest of the table if you keep diddling with it.

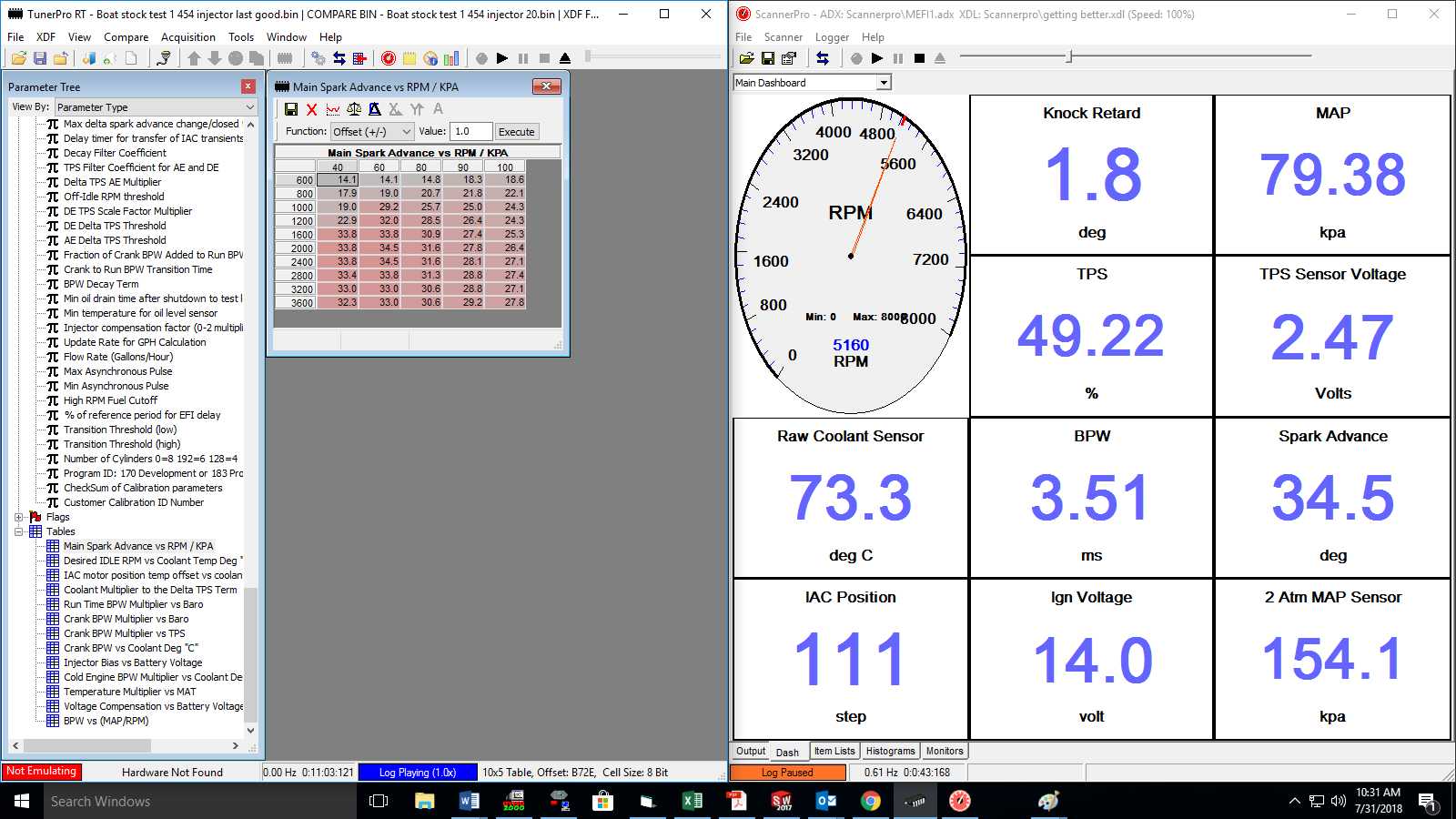

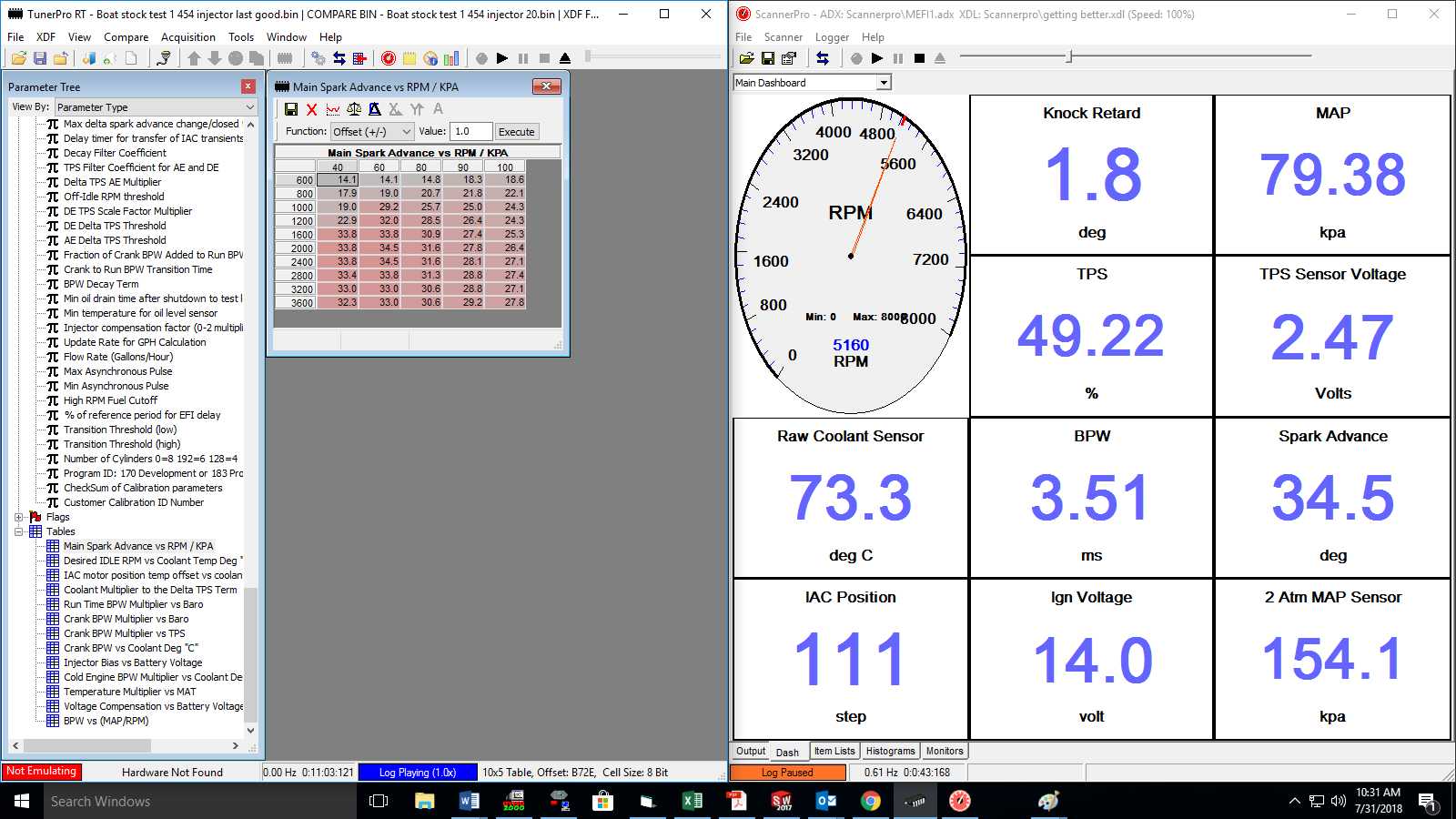

Here are 3 examples that will hopefully get you started.

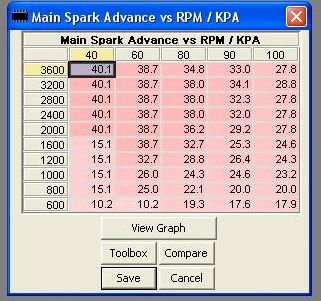

This is a bone stock Merc 350 Mag EFI/MP timing table circa 1995 MEFI 1, non-Vortec head model. Sort of pre Scorpion motor. Keep in mind your version of ScannerPro inverts the tables compared to my version.

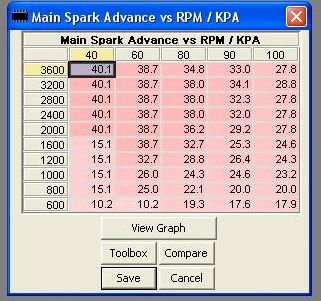

This is a Merc Scorpion 377 timing table

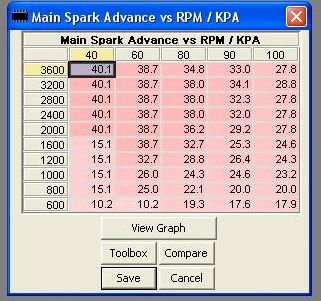

This is the load currently on my motor (377 stroker, standard bore)

Look how much more timing the non-Vortec head took in the mid-range as compared to the Vortec Scorpion (middle chart) and my load using Dart heads. I could likely plug a little more timing in this midrange on mine but it's splitting hairs and depending on atmospherics will occasionally tickle the knock sensor.

In addition when looking at knock, observe the knock retard to see how much spark is actually getting taken out. It often only needs to pull maybe a half degree to 2 degrees of timing for a short duration then its back to normal. The times where it pulls 8-9 degrees are the zones that really get my attention. You can control how much spark it takes out, the max it takes out and how fast it feeds it back in. BUT!!! I don't mess with those! Stock works well enough.

Another item to consider is if you have MBT in your spark system (Mean Best Timing). During steady state the ignition will advance until it senses either knock OR rpm reduces which effectively hits peak torque. This is most efficient for cruise. However, this is transparent to the end user IF installed unless you are watching it on ScannerPro. Merc employed this on a few motors, perhaps still to this day but I'm don't constantly follow all the latest systems.

The timing value you see on Scanner Pro should be nearly equal to the cell value in the ECM. There may be some slight differences as F1 slope modifier and a few other parameters may be temporarily altering the value a bit. But in general the values should match very closely.

I'm running Dart Iron eagles and did some timing experimentation. I ran VP110 race gas so I could 'jack' the timing up to see if anything could be gained. I was up to 38 degrees at WOT but didn't see ANY gain. I did alter the fuel tables for the VP110 as its stoic is different than regular gas. Sweet spot is between 32-34 degrees. If you are tickling the knock sensor just pull about half a degree of timing in that cell and try again.

I would set your base timing and leave it. This will have a global affect on the rest of the table if you keep diddling with it.

Here are 3 examples that will hopefully get you started.

This is a bone stock Merc 350 Mag EFI/MP timing table circa 1995 MEFI 1, non-Vortec head model. Sort of pre Scorpion motor. Keep in mind your version of ScannerPro inverts the tables compared to my version.

This is a Merc Scorpion 377 timing table

This is the load currently on my motor (377 stroker, standard bore)

Look how much more timing the non-Vortec head took in the mid-range as compared to the Vortec Scorpion (middle chart) and my load using Dart heads. I could likely plug a little more timing in this midrange on mine but it's splitting hairs and depending on atmospherics will occasionally tickle the knock sensor.

In addition when looking at knock, observe the knock retard to see how much spark is actually getting taken out. It often only needs to pull maybe a half degree to 2 degrees of timing for a short duration then its back to normal. The times where it pulls 8-9 degrees are the zones that really get my attention. You can control how much spark it takes out, the max it takes out and how fast it feeds it back in. BUT!!! I don't mess with those! Stock works well enough.

Another item to consider is if you have MBT in your spark system (Mean Best Timing). During steady state the ignition will advance until it senses either knock OR rpm reduces which effectively hits peak torque. This is most efficient for cruise. However, this is transparent to the end user IF installed unless you are watching it on ScannerPro. Merc employed this on a few motors, perhaps still to this day but I'm don't constantly follow all the latest systems.

I pulled the boat out of the garage last night and hooked it to the hose. Set initial back to 8 degrees.

I worked over the entire timing table, based off of your info and pictures you posted. I figured out cranking timing comes from the 600 RPM row, in the high MAP region. So by having the timing set too high here, it was making the boat hard to start. I get a chance I will post a picture of mt timing table.

Going to try and get her out this weekend, for some more test and tune.

#64

Registered

Thread Starter

Did some tuning this past weekend. I ended up finding an original set of GM 454 TBI injectors I had in my tool box, so I swapped them out, I was suspecting some fueling issues with the aftermarkets. All that did was lean my entire tune out a little and pretty much forced me to start over. So I started over with the stock .bin. Initial timing at 8 degrees, and went from there. My fueling is very close, 12-12.5 everywhere except idle which is 13.5. I get a little blip of spark knock when I accelerate out of the hole. I can not go full throttle out of the hole or it knocks, I have to ease into it. If I hammer it, the AFR goes really rich, like the PCM has an acceleration enrichment being activated. But if I ease it out of the hole AFR stays around 12 and she takes off, with maybe just a blip of knock. It also goes rich when I am decelerating. I have tried lowering the BPW in the 40 KPA column, that helped.

I see there are some scalars that may or may not help with this

Delta TPS AE Multiplier

DE Delta TPS Threshold

AE Delta TPS Threshold

DE TPS Scalar Factor Multiplier

When I started over with the tune I forgot to raise the fuel cut off form 4800 to 5500, and could not figure out why around 4800 the wide band would go nuts, and the boat would knock like crazy. The MEFI-1 has a crappy way of doing this. It cuts fuel, but not timing, making the boat knock like crazy. Anyway, I finally was like oh yeah...duh! I changed the fuel cut off to 5500 RPM.

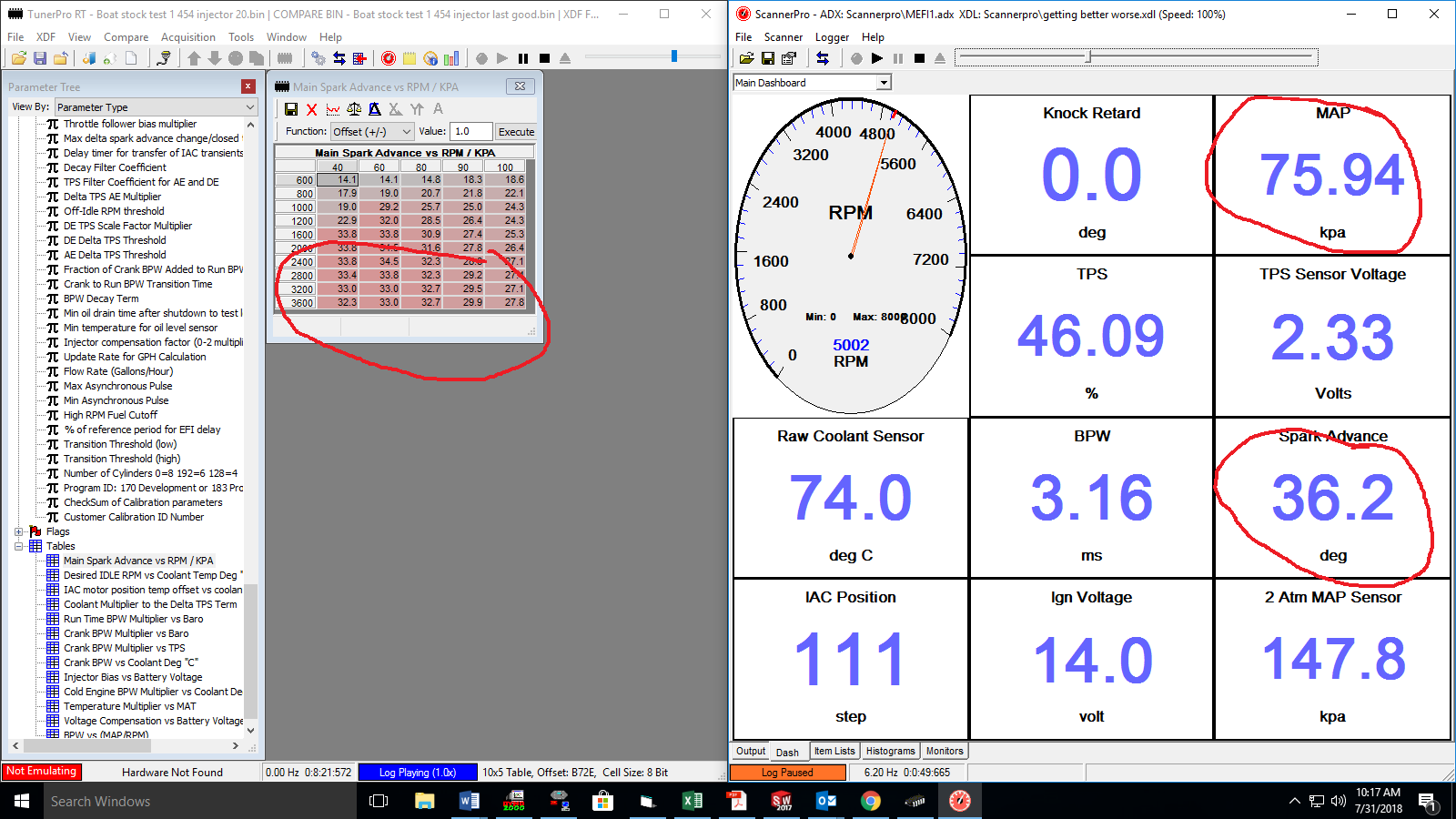

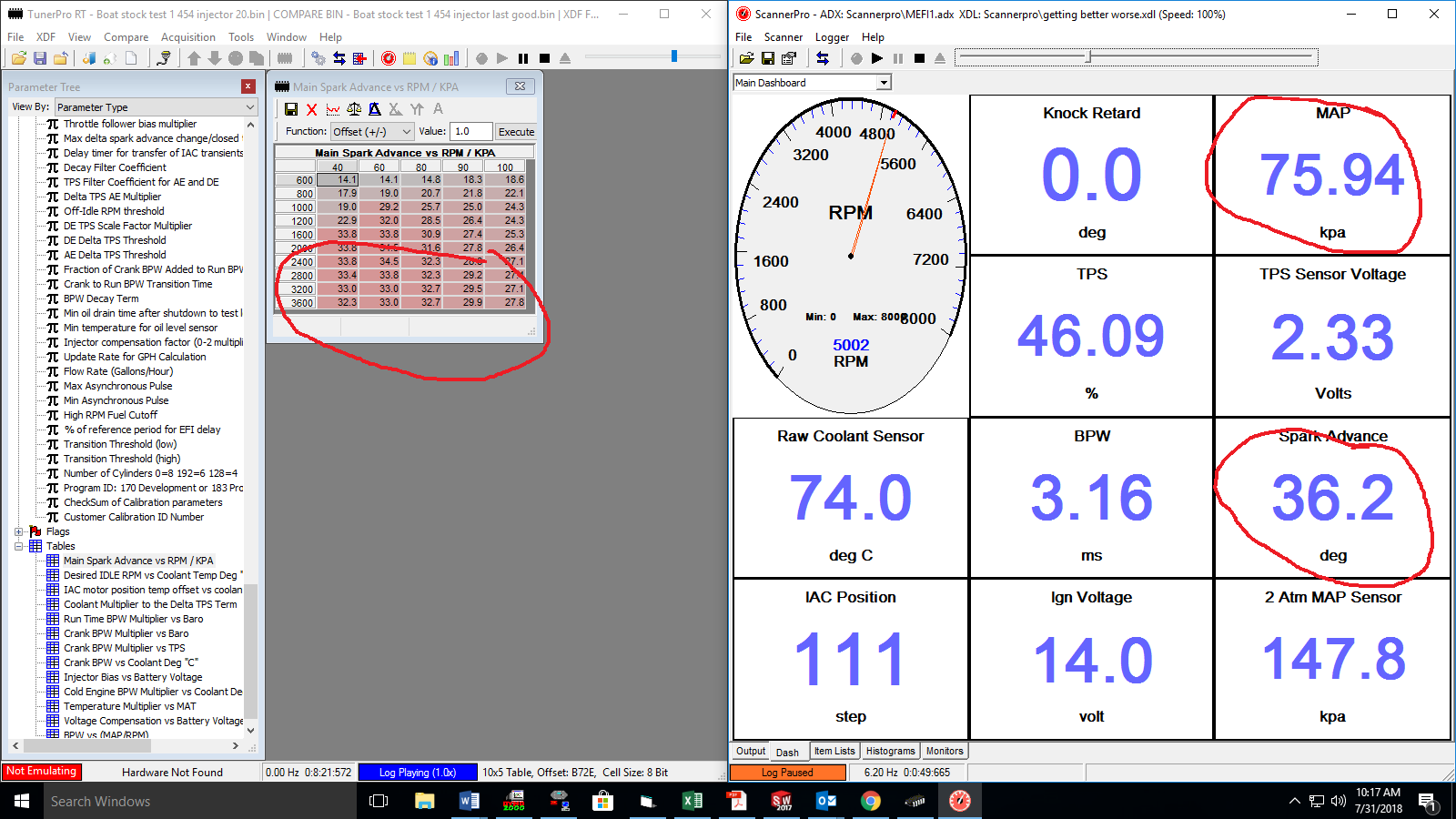

Here is the other issue I am having. The log from scanner pro does not match the timing I have in my main timing table. There is something advancing the timing.

I see there are some scalars that may or may not help with this

Delta TPS AE Multiplier

DE Delta TPS Threshold

AE Delta TPS Threshold

DE TPS Scalar Factor Multiplier

When I started over with the tune I forgot to raise the fuel cut off form 4800 to 5500, and could not figure out why around 4800 the wide band would go nuts, and the boat would knock like crazy. The MEFI-1 has a crappy way of doing this. It cuts fuel, but not timing, making the boat knock like crazy. Anyway, I finally was like oh yeah...duh! I changed the fuel cut off to 5500 RPM.

Here is the other issue I am having. The log from scanner pro does not match the timing I have in my main timing table. There is something advancing the timing.

#65

Registered

Thread Starter

As you can see above, nowhere in my timing table do I have 36 degrees of timing. Here is a picture of my timing table, the best its ran so far. Still get some knock. This is about as high as it gets, but I can hear and feel it when it happens. I pulled a couple plugs, last night, they look good to me, but wonder if maybe I should go a step cooler. The plugs are Autolite 4063's which is about an 8 heat range in an NGK. I am thinking about going to a BR9ES NGK, colder plug.

#66

Registered

iTrader: (1)

Don't know why you would need a colder plug than an -8/ Jeez, a -7 should be fine when everything is tuned right. But, as Darin Morgan famously says, 'let the motor tell you what it wants.'

#67

Registered

Thread Starter

What do you think, by the way the pug looks? This engine should have easy 10.5:1 compression, stock was 9.3:1, the stock plug is a 6, I thought the rule of thumb was to go a couple plugs cooler for every point of compression so thats why I am at an 8. I was expecting the plug to be a little more tan than that, with the boat running the AFR it does.

#68

Registered

iTrader: (1)

And that is prob your source of spark knock...too high of compression and too little of a cam for such high compression.

And I'm not going to ask why such high compression. Scratch that, why so high ? LOL at myself.

LOL at myself.

And I'm not going to ask why such high compression. Scratch that, why so high ?

LOL at myself.

LOL at myself.

#69

Registered

iTrader: (1)

Did you make templates out of stoc paper/manilla, etc to see how bad the ports line up ?

Are your inline silencers the type that puts a flat plate in the middle of them ?

#70

Registered

Thread Starter

I used the new D port gaskets to match the manifolds to the new heads, they were not off as bad as I thought they were. Just had to do some minimal work with a die grinder on the manifold ports to make them line up.

I am running GGB muffler inserts. They are the discs, with holes in them.