LS Build: In Progress

#61

Registered

Good power cam. See how the int/ex split forces the exhaust closing past 0 (8in headers would be great. We run dry down here, screw reversion.t your case). I can see why you had to go dry. Good for scavenging. Bad for reversion. I opted the other way to keep the db down and headers are not in the budget. Yet........... lol. Any dyno numbers??

#62

Registered

Thread Starter

Are you using a cam design program? Or some predictive modeling? Does seem with the cam Corey has that long tube headers would be nice, as for reversion. Down here we just run dry headers, screw the noise and there are no laws. I think ICDPLE uses some type of muffler on his dry pipe blower motor that worked good. I THINK,,,,,

#64

Registered

Thread Starter

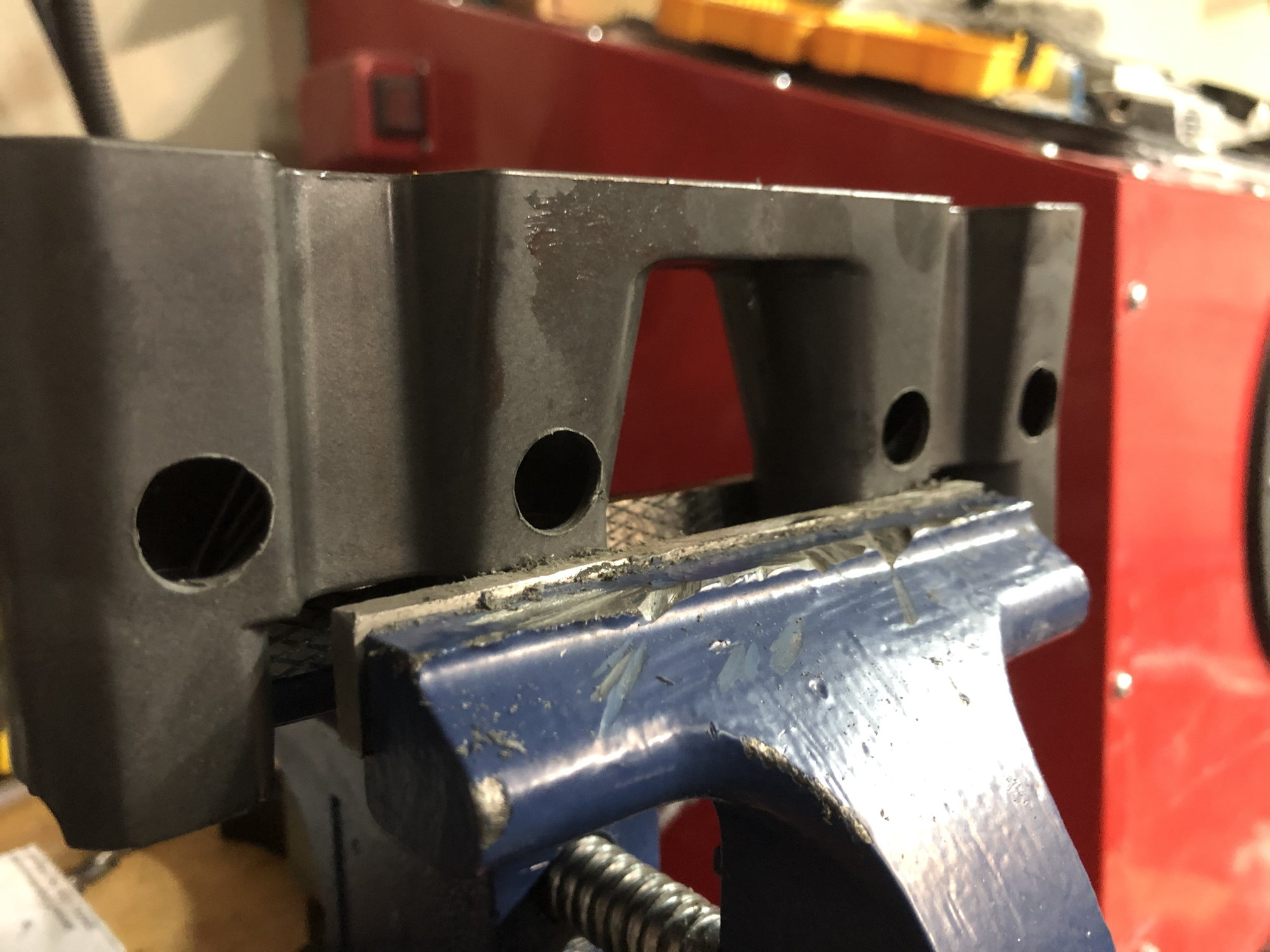

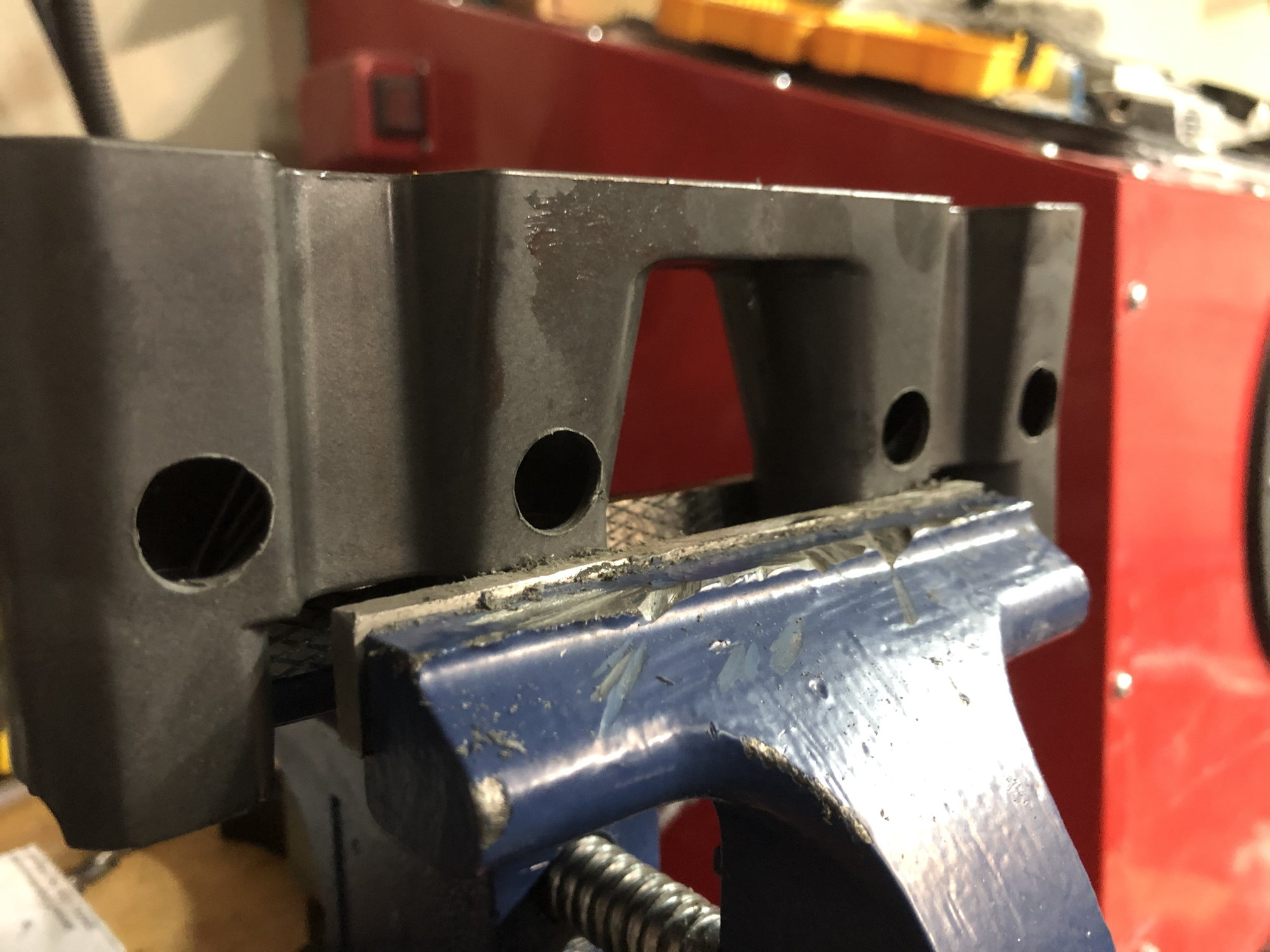

Oiling mods. 1/2” holes drilled in lifter trays for drainback. Still need to debur I know. Also pic of billet barbell for back of block. Much tighter tolerances= less oil seeping by.

#65

Registered

One thing to keep in mind is the oil to the head is the only means to cool the valve springs...big issue on BB's not sure on the LS setups, none of the ones we run or have we did anything to the oiling other than a ported H/P oil pump..Rob

#67

yep...goes in from the back and directs oil into the oil filter...if it wasn't there then unfiltered oil would go straight up to the bearings. The stock plastic ones have a thicker shaft that's more "restrictive" and they fit kinds loose in the bore...these are made to be tighter so less likely of any unfiltered oil getting by.

__________________

-Wally

Money can't buy happiness, but it can buy horsepower. And I've never seen a sad person hauling a$$!

-Wally

Money can't buy happiness, but it can buy horsepower. And I've never seen a sad person hauling a$$!

#69

Registered

Thread Starter

Im using 2008 ly6 blocks. Chose these due to priority main oiling being gen iv which requires vvt delete. I went iron because of strength( found out how much a aluminum ls2 could handle the hard way at 22psi boost in the gto). Way less cylinder distortion. Also much less swing in bearing clearance while waiting for blocks to warm up. Msin reason is raw water cooling. I do not run in salt and am saving an astronomical amount of money by avoiding closed cooling. Mainly out in havasu and Phoenix.

#70

Registered

Im using 2008 ly6 blocks. Chose these due to priority main oiling being gen iv which requires vvt delete. I went iron because of strength( found out how much a aluminum ls2 could handle the hard way at 22psi boost in the gto). Way less cylinder distortion. Also much less swing in bearing clearance while waiting for blocks to warm up. Msin reason is raw water cooling. I do not run in salt and am saving an astronomical amount of money by avoiding closed cooling. Mainly out in havasu and Phoenix.

What would you do cast or AL?