Fountain 47, 2372cid single engine diesel

The following 2 users liked this post by Twin O/B Sonic:

Gimme Fuel (10-09-2023), ksalmine (10-08-2023)

The following users liked this post:

ksalmine (10-08-2023)

The following users liked this post:

ksalmine (10-08-2023)

The following users liked this post:

ksalmine (10-08-2023)

#255

Registered

Thread Starter

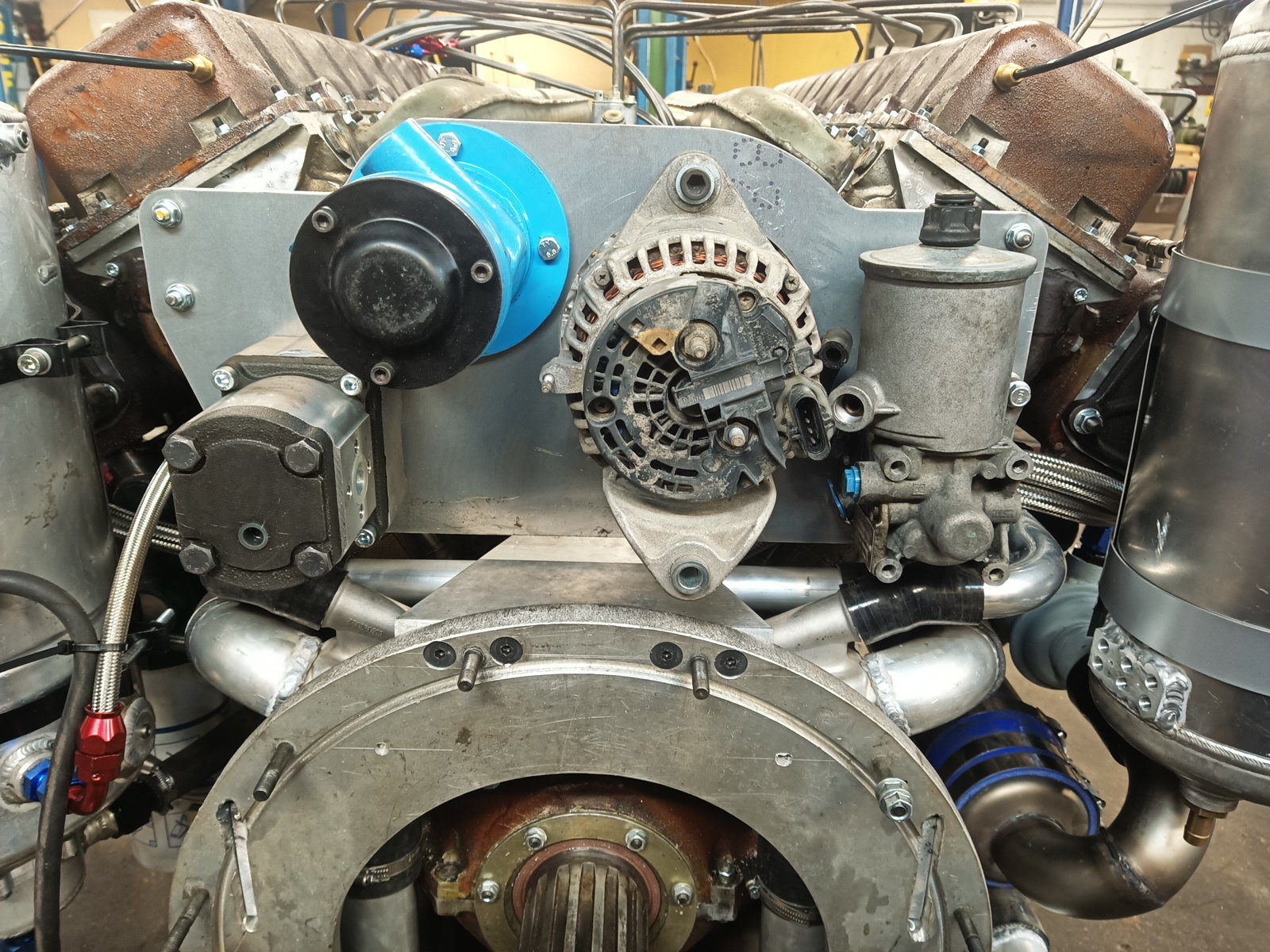

Accessory drive hydraulic pump is coupled to engine original alternator drive. It's driven from timing bevel gear, straight from crankshaft and spin 1.5 times faster than crank. 2 series 12cm3 pump max is 3750rpm so it should work fine. Raw water pump will be hydraulic driven and get own 16cm3 motor to reduse rpm because its huge size water pump, accessory drive motor is 12cm3 so drive pulley run 1.5 times rpm than engine.

This pump will make transmission hydraulic pressure also, I raise it from 16bar to 30bar to keep friction plates alive. Transmission original pump is not use anymore and pressure control is easier to adjust when it's external.

Raw water pump and accessory drive motors will be connect to series with some pressure contol valves. I think this is not a usual way to manage this things

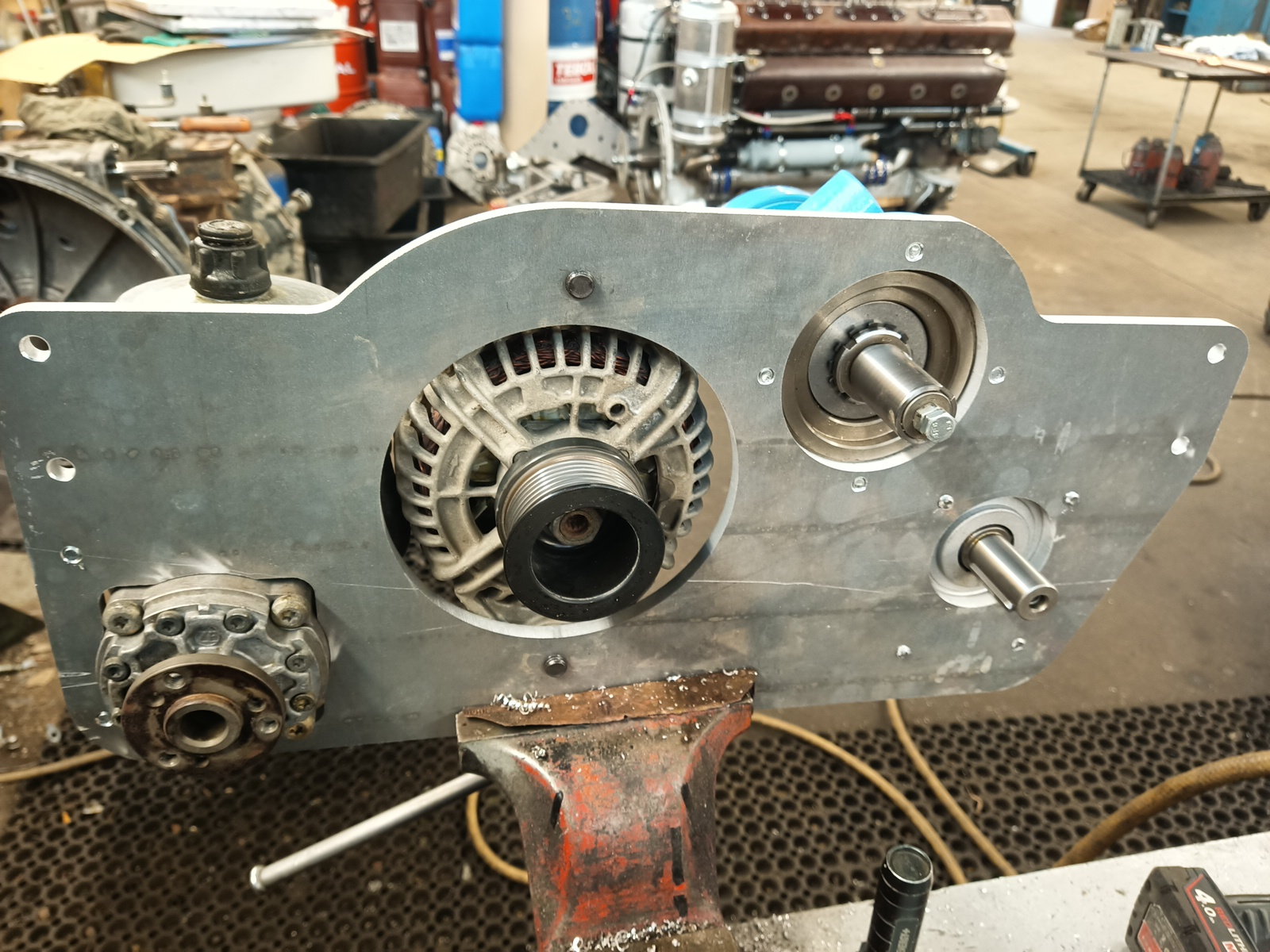

Accessory drive have hydraulic motor, 24vdc 100A alternator, crankcase vacuum pump and Mercedes Benz power steering pump. MB pump is actually dual pump, hydraulic rear suspension level adjustment have been working by this pump. I try use extra pump for splitbox oil filtration and cooling purpose.

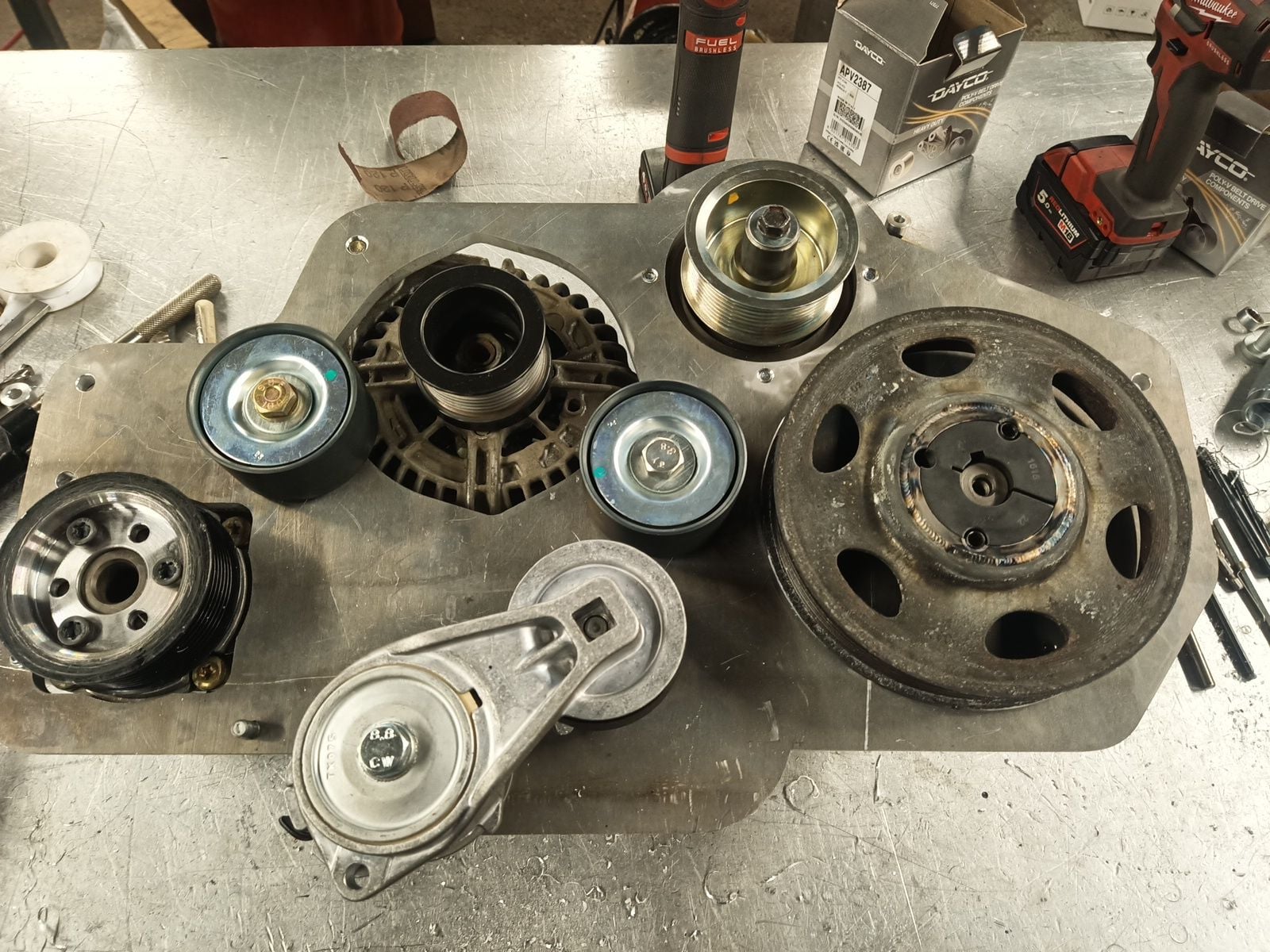

Automatic belt tensioner and few guide pulleys have to engineer to get job done.

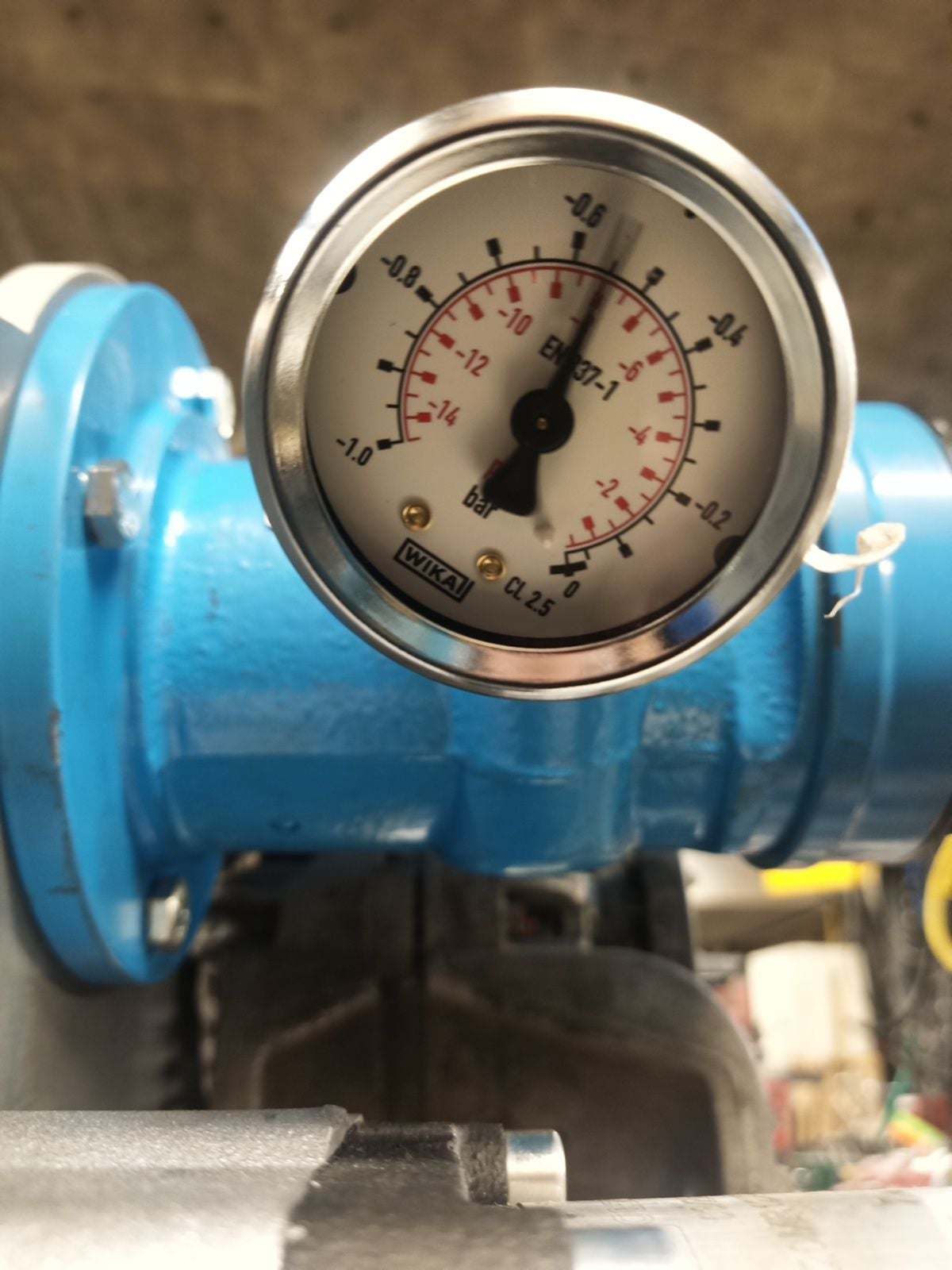

Crankcase vacuum pump is big atlas copco pneumatic motor, but it may work as vacuum pump, we will find it out soon. 0.5bar vacuum should keep oil inside engine, if not, I have a problem.

Last edited by ksalmine; 10-08-2023 at 11:56 AM.

The following 5 users liked this post by ksalmine:

Gimme Fuel (10-09-2023), Markus (12-08-2023), RSCHAP1 (10-09-2023), Samer (10-08-2023), Twin O/B Sonic (10-08-2023)

The following users liked this post:

Twin O/B Sonic (10-08-2023)

#257

Registered

Thread Starter

Accessory drive package is ready now. I screwed up first aluminium plate, tensioner and guide pulleys had not enough space to fit so new one had to cut but everything fit now nice. I'm little scared how taper lock welded pulley works, will it run straight or not? Belt offset is easy adjust now and it was way little time consuming than make special hub for pulley.

3/4" hydraulic T fitting transform to vacuum regulator, I found good spring in it, piston is self made of polyacetal plastic and valve is fully adjustable. Air motor pull good vacuum when I try it by power drill so vacuum have to regulate about 0.3-0.5 bar under atmosphere. Breather hose is AN16 from engine to pump and AN12 pump to dry sump tank, I hope they are big enough.

Original breather is modified to catastrophic valve. End cap is hold in place by only O ring tension and vacuum help keep it in place also. If engine blows up, crack piston or seized piston ring, vacuum pump may not have enough flow and crankcase goes positive pressure, it will be worse scenario. Polyacetal end cap is made to fly away and open 2" breather to engine room, it's a safety valve and may avoid bigger explosion.

Next thing is buy full backpag hose clamps, make cooling system leak proof and build somekind cooling system pressure control valve. After that engine can started again for longer period to find out how vacuum keep oil inside engine and try adjust idle quality. I don't like "blower surge" like idle.

Extension boxes should be ready next week and other driveline components need to design soon. Long post but hope you like things going forward.

The following 8 users liked this post by ksalmine:

Gimme Fuel (10-30-2023), IGetWet (10-17-2023), kidturbo (10-18-2023), Markus (12-08-2023), resurrected (10-24-2023), RSCHAP1 (10-17-2023), Samer (10-22-2023), thegoodson (10-16-2023)

#258

Registered

Thread Starter

First bigger adversity is half repaired now. I pressure tested cooling system by compressed air and engine leak about dozen points, it was dissappointing. I figured out that Locktite 577 and 55 should used never again, every other thread was leaking a little. I pull exhaust manifold off and all brass water passange sleeves that leak. Fortunately self made special tool grabbed enough to get sleeves out.

Sleeves have M33x1.5 threads and this time I put good engine sealant to it flange and Locktite 542 hydraulic sealant to thread, they can't leak anymore. Water passange O rings had too low tension also, they were sold at 21x3mm but diameter was really 2.85-2.92mm so tension was not good. I found 21x3 viton O rings, they are really 3mm and feels much better in place.

Oil filter housing bracket was mount to M33x1.5 water plugs before but mounting have serious change to fail so I mill manifold flat and make 10mm thick aluminium adapter plate.

Homemade heat exchanger was biggest worry, will it leak or not, but luckily only one pinhole at so many solders. Its soldered with phosphorus copper, easy to repair. Exchanger size is another big question, I try calculate it and it should be big enough but there is many variables in calculations. 70 meters 8mmx0.8mm tube get about 1.2 square meter cooling area.

Sleeves have M33x1.5 threads and this time I put good engine sealant to it flange and Locktite 542 hydraulic sealant to thread, they can't leak anymore. Water passange O rings had too low tension also, they were sold at 21x3mm but diameter was really 2.85-2.92mm so tension was not good. I found 21x3 viton O rings, they are really 3mm and feels much better in place.

Oil filter housing bracket was mount to M33x1.5 water plugs before but mounting have serious change to fail so I mill manifold flat and make 10mm thick aluminium adapter plate.

Homemade heat exchanger was biggest worry, will it leak or not, but luckily only one pinhole at so many solders. Its soldered with phosphorus copper, easy to repair. Exchanger size is another big question, I try calculate it and it should be big enough but there is many variables in calculations. 70 meters 8mmx0.8mm tube get about 1.2 square meter cooling area.

The following 7 users liked this post by ksalmine:

AllDodge (10-31-2023), Gimme Fuel (11-06-2023), kidturbo (11-03-2023), Markus (12-08-2023), resurrected (11-06-2023), smashm (11-02-2023), Twin O/B Sonic (11-01-2023)

#259

Registered

Thread Starter

Extension boxes have arrived! Next town metal work shop make awesome work, they are really good quality. Transom mating face and drive face plate are 12mm S355 steel, sides are 5mm steel. I maybe make mistake and over design them, weight is 45kg (99lbs) each. There is unnecessary weight, but better this way than that they break and sink my boat. Aluminium construction could have been better way but I have to economize and keep cost down.

They have 15 degree angle, same that transom angle so drives should be 0 degree ange when they are parallel to bottom. That should be full throttle situation.

Engine room side reinforcement and trim cylinder mount plates are 304 stainless steel for better outlook, boxes will get sandblast and epoxy coat.

You can guess what hole is just above drive mount hole?

My friend have big milling machine and he promise to make faces straight, my machine have not enough travel to do that.

I have never ever even see extension box in live before, but I hope these self design boxes do their jos as planned.

They have 15 degree angle, same that transom angle so drives should be 0 degree ange when they are parallel to bottom. That should be full throttle situation.

Engine room side reinforcement and trim cylinder mount plates are 304 stainless steel for better outlook, boxes will get sandblast and epoxy coat.

You can guess what hole is just above drive mount hole?

My friend have big milling machine and he promise to make faces straight, my machine have not enough travel to do that.

I have never ever even see extension box in live before, but I hope these self design boxes do their jos as planned.

The following 7 users liked this post by ksalmine:

Gimme Fuel (11-06-2023), hblair (11-25-2023), kidturbo (11-28-2023), resurrected (11-06-2023), RSCHAP1 (11-06-2023), scippy (11-28-2023), Twin O/B Sonic (11-04-2023)

#260

Registered

Thread Starter

Trim cylinders are close to ready, upper end need cnc turned aluminium bronze pieces for ball joint, they are next on list. Whole cylinders are self design and my friend turned tubes and shafts by manual lathe. I have small engine cylinder hone and that make good surface to turned stainless tube, seals should be work on that surface.

Drives are fully assembled with all seals and right clearances.

It was difficult to drill small oil holes to bronze ball so I can put hose and bottle in engine room. Small reservoir bottle is necessary because if I fill drives at 20*C temperature and put boat to 10*C water, they will get some vacuum inside. Drives will make some heat at bigger power levels so they get pressure inside. Reservoir bottle help keep just atmospheric pressure there, its better every way.

Ball joint lubrication passanges is also drilled, there is tiny channel in stainless housing that get grease to ball joint, there will be hose to engine room so its easy to lubricate when boat sit in water. If X-ring seal broke in middle of summer, I have not to get boat out of water, just give small quantity stiff grase to joint so it won't leak water to boat.

The following 3 users liked this post by ksalmine: