Tunell raaammm!!!!

#72

Having second thought on the solid roller.

It`s another $2k in valve covers.

My manifolds wont let me reach the bottom valve cover screws.

Id have to take the tips, tails and manifolds off to get to them. That`s weekend job.

They are close so loosening one to get to the bolts isn`t an option either

It`s another $2k in valve covers.

My manifolds wont let me reach the bottom valve cover screws.

Id have to take the tips, tails and manifolds off to get to them. That`s weekend job.

They are close so loosening one to get to the bolts isn`t an option either

#73

Registered

iTrader: (7)

Damm those are tight. I’m really curious if my Hardin marine valve covers and stellengs are going to be an issue. What does mike recommend on checking lash. Your inside exhaust must be a real C…S…..

I only have 33 1/2” center to center but have a good 1 1/2” + clearance btwn the two.

pretty certain I can get the covers off with out touching the exhaust but…. I’ll probably only ck lash once a season. Maybe twice or if I’m down on power etc.

I only have 33 1/2” center to center but have a good 1 1/2” + clearance btwn the two.

pretty certain I can get the covers off with out touching the exhaust but…. I’ll probably only ck lash once a season. Maybe twice or if I’m down on power etc.

Last edited by getrdunn; 11-30-2021 at 01:13 PM.

#74

Charter Member #40

Having second thought on the solid roller.

It`s another $2k in valve covers.

My manifolds wont let me reach the bottom valve cover screws.

Id have to take the tips, tails and manifolds off to get to them. That`s weekend job.

They are close so loosening one to get to the bolts isn`t an option either

It`s another $2k in valve covers.

My manifolds wont let me reach the bottom valve cover screws.

Id have to take the tips, tails and manifolds off to get to them. That`s weekend job.

They are close so loosening one to get to the bolts isn`t an option either

#75

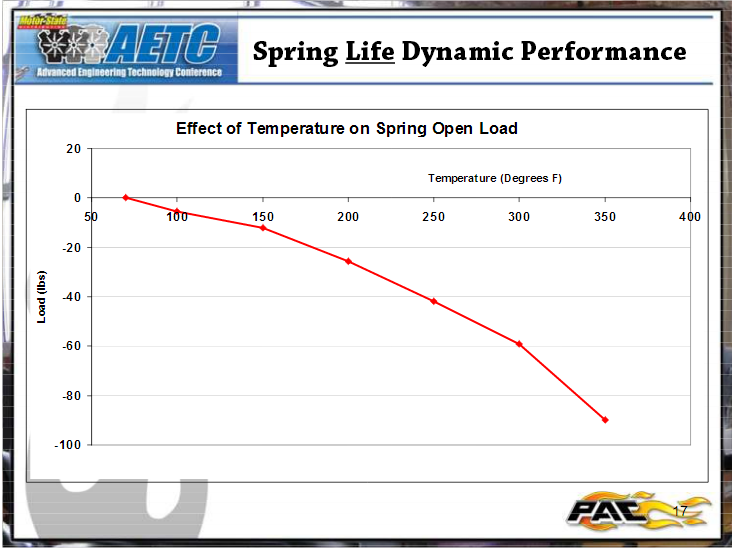

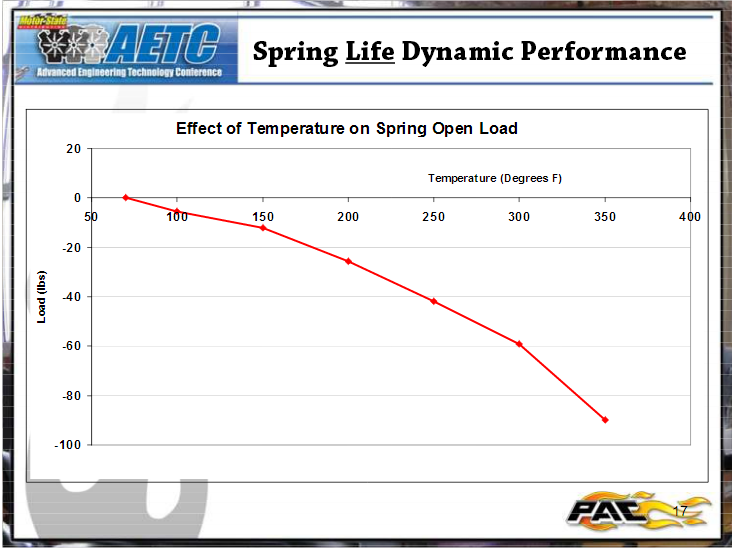

I really feel the spring oilers help, after a few years on my tool room springs they lost very little spring pressure. I run over 225/575 spring pressures .

I believe the Merc. 850/1075 came stock with spring oilers. Id rather not eliminate them .

Found these interesting..

I believe the Merc. 850/1075 came stock with spring oilers. Id rather not eliminate them .

Found these interesting..

The following 3 users liked this post by ICDEDPPL:

#76

Registered

iTrader: (7)

Thought I’d post my older cooling thread since you touched on the subject. I’m finally nearing this point myself and are some good posts here including yours.

Ideal method of engine cooling for most consistent temps

Ideal method of engine cooling for most consistent temps

#77

Registered

iTrader: (7)

I really feel the spring oilers help, after a few years on my tool room springs they lost very little spring pressure. I run over 225/575 spring pressures .

I believe the Merc. 850/1075 came stock with spring oilers. Id rather not eliminate them .

Found these interesting..

I believe the Merc. 850/1075 came stock with spring oilers. Id rather not eliminate them .

Found these interesting..

No need buy the expensive PL’s either. Just a DC pump (explosion proof), dash switch and a little plumbing. About 125.00 aside.

Last edited by getrdunn; 12-01-2021 at 09:22 AM.

#78

Removing the valve covers without pulling anything else was my goal with KE covers. My application is a single engine, Dart big M, Dart pro one 335, Jessel sportsman steel rockers, BDS 1071, and CMI E tops. Right off the bat one of the headers touched the valve cover I assume because the Dart Pro Ones have a .300" raised exhaust port.. I am in the process of making 3/8" aluminum spacers to go between the headers and heads in order to give enough clearance to take the upper part of the valve cover off the adjust the mechanical roller lifters. Doing this I only have to remove the throttle cable bracket off the supercharger and the covers will come off with no other problems. As far as spring KE spring oilers I elected not to go with them yet and I understand that they are basically a spacer that replaces the gasket between the head and valve cover and would add to the clearance problem. A twin engine application depending on the exhaust and heads may have issues also.

The following users liked this post:

articfriends (12-01-2021)

#79

Platinum Member

Spring oilers are definitely worth doing. I run an oil return line from the back of the head to the pan. They will also raise your oil temps, so make sure you have enough cooling. More frequent oil changes also. You will definitely see better spring life.

The following users liked this post:

articfriends (12-01-2021)

#80

Platinum Member

iTrader: (1)

So did you see spring rate degradation then added spring oilers and it was less? When you say "spring oilers", you mean a bar or spacer fed with oil to shoot oil on the springs? I been following the lifter thread and this thread with great interest, I will add THIS, before Morel lifters had issues, I ran Morel lifters, good pushrods, Isky tool room springs with 190ish seat/490 open, .390/.380 lobe, TD shaft rockers with a .040 "spring oiler option" (was like a 20$ upgrade), no other "heroics", Bob M cam, boosted motor made over 1000 hp, was held at wot for 10+ minutes at a time at 6300, 12 to 14 lbs of boost and I set my "freshen/rebuild" interval at 100-120 hrs mainly when I started to see annual leakdown rates get past 30%. At that point my springs had decayed 5 lbs or so seat and maybe 10,15 lbs open. Now, at that time I replaced springs and lifters everytime, sold the other mint used parts for 35 to 50% of cost of new vs running them until they failed with FULL disclosure of their histroy. My oil temp ran 180 to 220 max. Ive since switched to Johnson lifters with their lowly .700 wheel and used them in quite a few other customers builds with no reported problems. I don't tell customers to attempt to run their blower motors for 300 or 400 hrs between freshen intervals, maybe Im overly cautious, maybe not. I think 55 mm cams, .904 lifters, jesel belt drives, dry sumps, solid lifters, etc are all "cool" upgrades BUT on these 6000, 6300 rpm motors is any of it really necessary. I HAVE used those things on 8000 rpm big blocks, Smitty

Last edited by articfriends; 12-01-2021 at 01:53 PM.

The following 3 users liked this post by articfriends: