Just Turbines

#102

Registered

Thread Starter

#104

Registered

Jpzaluski what do you think the inside of a commercial jet engine looks like that's been flying for thousands of hours! Kinda scary what is " acceptable damage" looks like...

#105

Registered

send a flock of birds thru. man oh man chik fric a see

#106

Registered

To answer your earlier question we use full Argon in Inconel repairs. Inco is difficult to weld (my opinion)- A welder once told me "Inco flows like a dog turd on a sidewalk". My welding skills are about like yours from what you described- maybe having someone that welds every day is a good choice- a fabricator that works with stainless unless there are some in the area that have worked with Inco, particularly turbine parts. You could get all your repairs identified and bring someone in- none of my business just a suggestion.

Anyway some things to think about- maybe what you have are very small areas that this doesn't pertain too- my free internet advice:

Clean/prep crack area

Bend/fit Cu chill to back up band so you don't blow through band when welding

Measure throat area before welding- top, middle and bottom- suction side vane to adjacent vane pressure side- if ring has separated then vanes have moved apart. You can compare to other unaffected throat areas. The tenon holes are machine pre-punched so likely throat openings within .005 or so of each other. Ideally all throat openings should be same or you get a once/rev stimulus on the downstream blading.

If cracking severe and subsequent weld is substantial you may need to spread & block the vanes apart with wooden blocks as the weld will shrink and pull them together. A function of experience- you could crack the welds around the tenons. One of the cracks appeared wide but hard to tell from photo- you could start with the minor ones first and monitor movement.

Gently preheat to 100 deg F with rosebud prior to welding (drive moisture from weld area)

You will need to grind/sand, shape and polish the weld after completion.

Enjoyed the gearbox photos...

I'll be on the east coast next week- can you finish up by then so we can go for a ride?

Lane

Last edited by 28 V; 11-15-2013 at 01:30 PM. Reason: added photos- area/chills

#107

Registered

Thread Starter

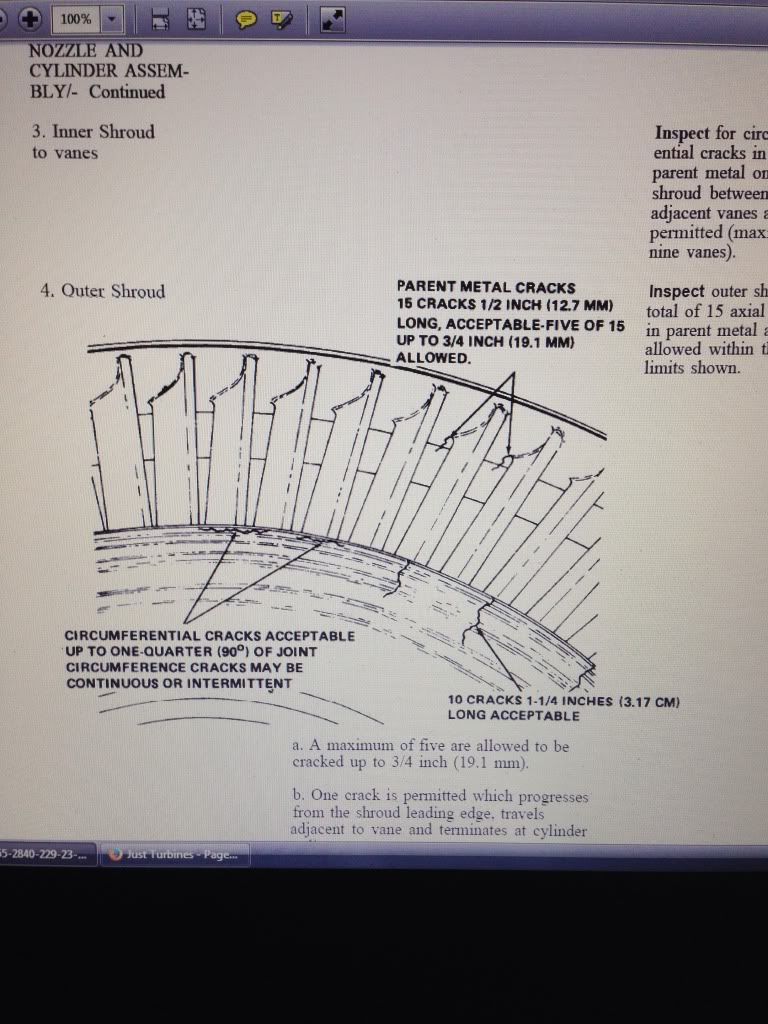

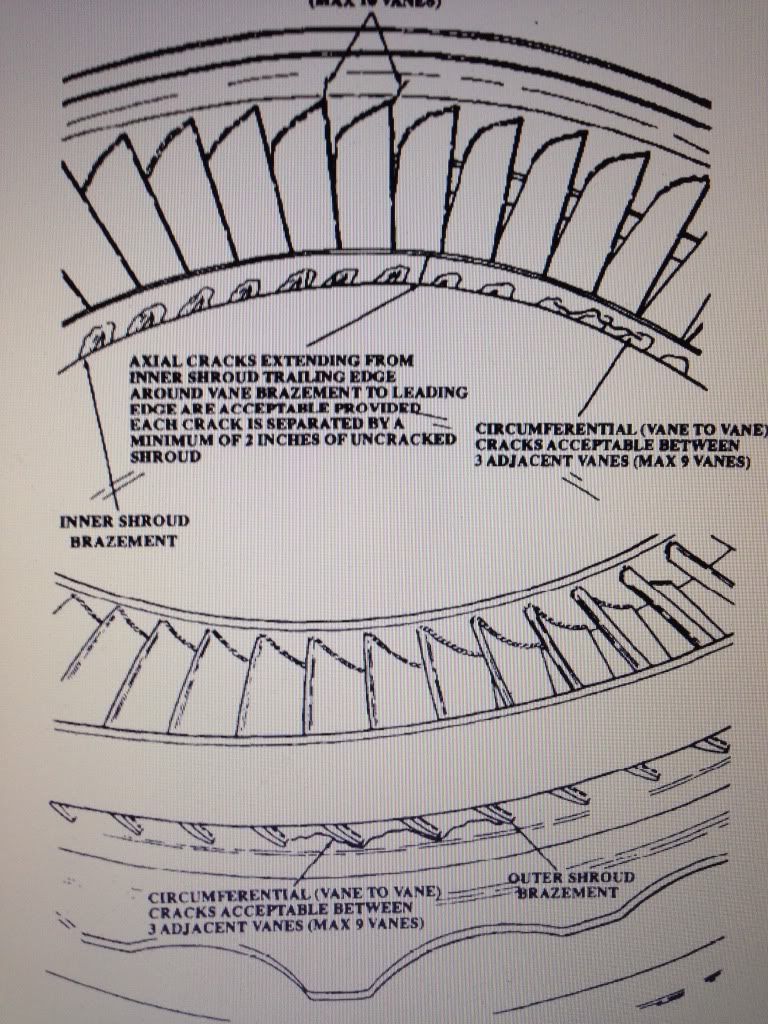

Interesting...more lenient than the "heavy duty" designs I'm familiar with- I suppose the question becomes- how fast is the growth rate?....When you will exceed the "critical crack size"..apparently quite some time!

To answer your earlier question we use full Argon in Inconel repairs. Inco is difficult to weld (my opinion)- A welder once told me "Inco flows like a dog turd on a sidewalk". My welding skills are about like yours from what you described- maybe having someone that welds every day is a good choice- a fabricator that works with stainless unless there are some in the area that have worked with Inco, particularly turbine parts. You could get all your repairs identified and bring someone in- none of my business just a suggestion.

Anyway some things to think about- maybe what you have are very small areas that this doesn't pertain too- my free internet advice:

Clean/prep crack area

Bend/fit Cu chill to back up band so you don't blow through band when welding

Measure throat area before welding- top, middle and bottom- suction side vane to adjacent vane pressure side- if ring has separated then vanes have moved apart. You can compare to other unaffected throat areas. The tenon holes are machine pre-punched so likely throat openings within .005 or so of each other. Ideally all throat openings should be same or you get a once/rev stimulus on the downstream blading.

If cracking severe and subsequent weld is substantial you may need to spread & block the vanes apart with wooden blocks as the weld will shrink and pull them together. A function of experience- you could crack the welds around the tenons. One of the cracks appeared wide but hard to tell from photo- you could start with the minor ones first and monitor movement.

Gently preheat to 100 deg F with rosebud prior to welding (drive moisture from weld area)

You will need to grind/sand, shape and polish the weld after completion.

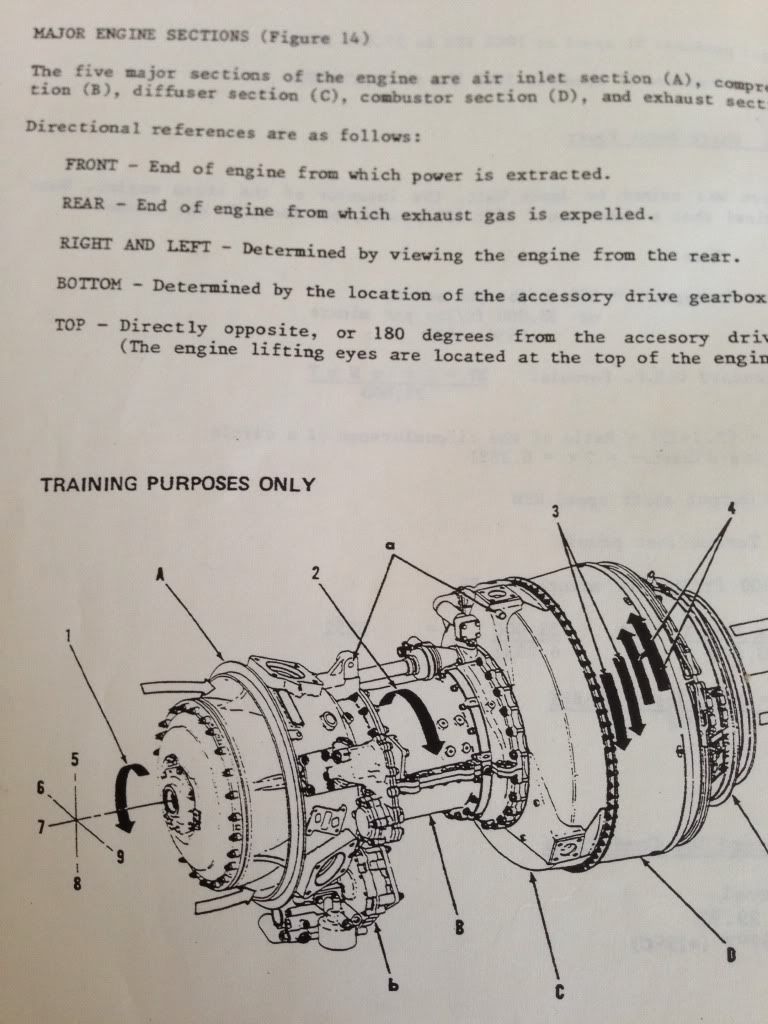

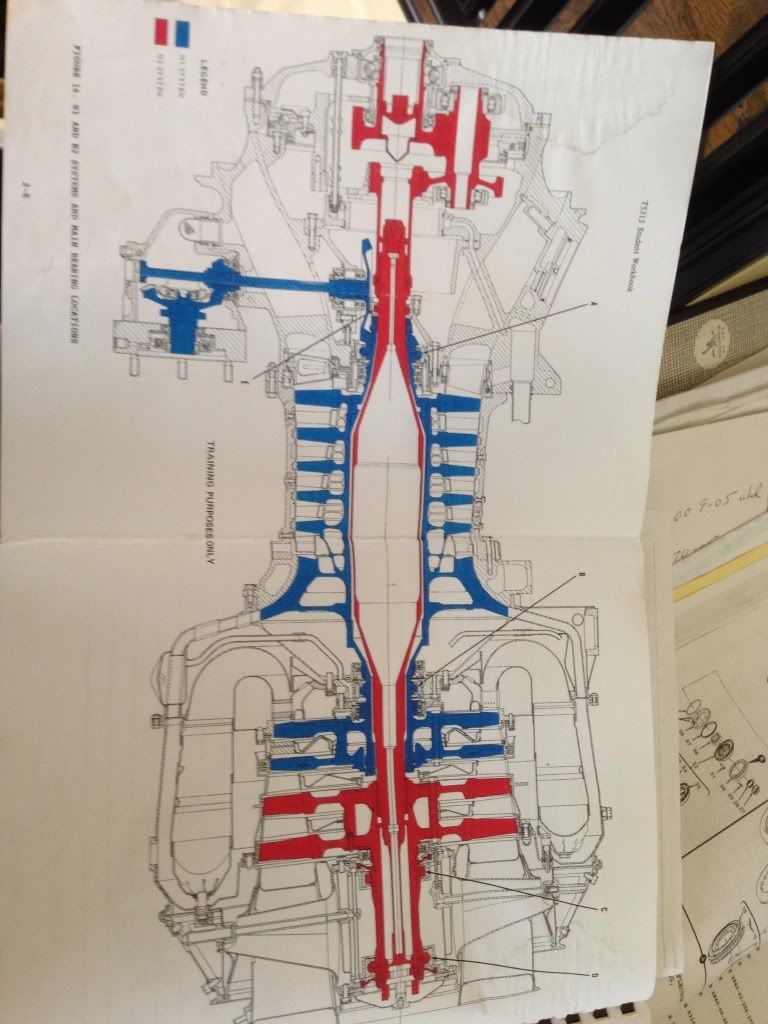

Enjoyed the gearbox photos...

I'll be on the east coast next week- can you finish up by then so we can go for a ride?

Lane

To answer your earlier question we use full Argon in Inconel repairs. Inco is difficult to weld (my opinion)- A welder once told me "Inco flows like a dog turd on a sidewalk". My welding skills are about like yours from what you described- maybe having someone that welds every day is a good choice- a fabricator that works with stainless unless there are some in the area that have worked with Inco, particularly turbine parts. You could get all your repairs identified and bring someone in- none of my business just a suggestion.

Anyway some things to think about- maybe what you have are very small areas that this doesn't pertain too- my free internet advice:

Clean/prep crack area

Bend/fit Cu chill to back up band so you don't blow through band when welding

Measure throat area before welding- top, middle and bottom- suction side vane to adjacent vane pressure side- if ring has separated then vanes have moved apart. You can compare to other unaffected throat areas. The tenon holes are machine pre-punched so likely throat openings within .005 or so of each other. Ideally all throat openings should be same or you get a once/rev stimulus on the downstream blading.

If cracking severe and subsequent weld is substantial you may need to spread & block the vanes apart with wooden blocks as the weld will shrink and pull them together. A function of experience- you could crack the welds around the tenons. One of the cracks appeared wide but hard to tell from photo- you could start with the minor ones first and monitor movement.

Gently preheat to 100 deg F with rosebud prior to welding (drive moisture from weld area)

You will need to grind/sand, shape and polish the weld after completion.

Enjoyed the gearbox photos...

I'll be on the east coast next week- can you finish up by then so we can go for a ride?

Lane

Excellent description!

Thank you

#108

Registered

Thread Starter

#109

Registered

Thread Starter

#110

Registered

Thread Starter